A Real-time Furnace Condition Evaluation Method of Roasting Furnace Based on Temperature Trend Feature Extraction

A feature extraction and roasting furnace technology, which is applied in the field of real-time furnace condition evaluation of roasting furnaces based on temperature trend feature extraction, can solve the problems affecting the stable control of the standard temperature of the boiling layer and the large time delay of the roasting furnace, so as to overcome the problem of large time delays. , Accurate temperature changes, reduce the effect of overfitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

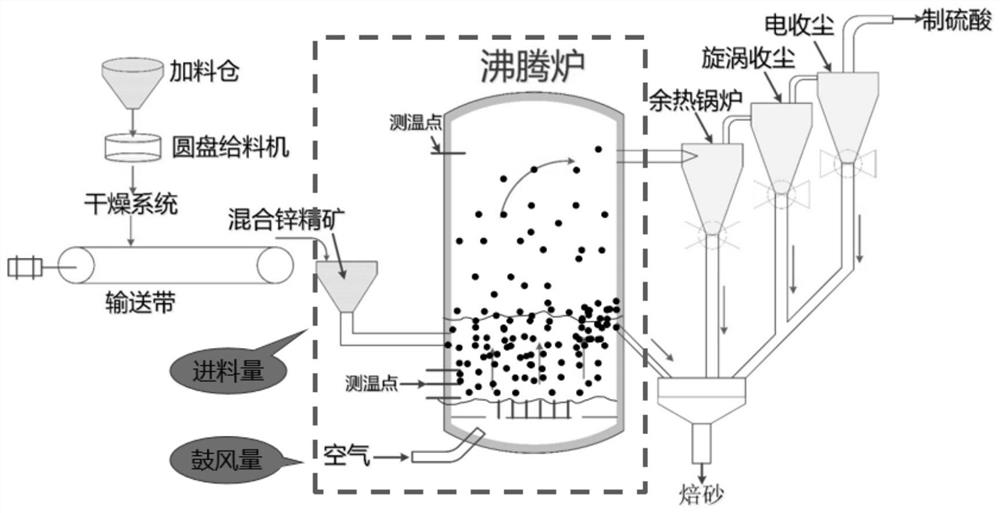

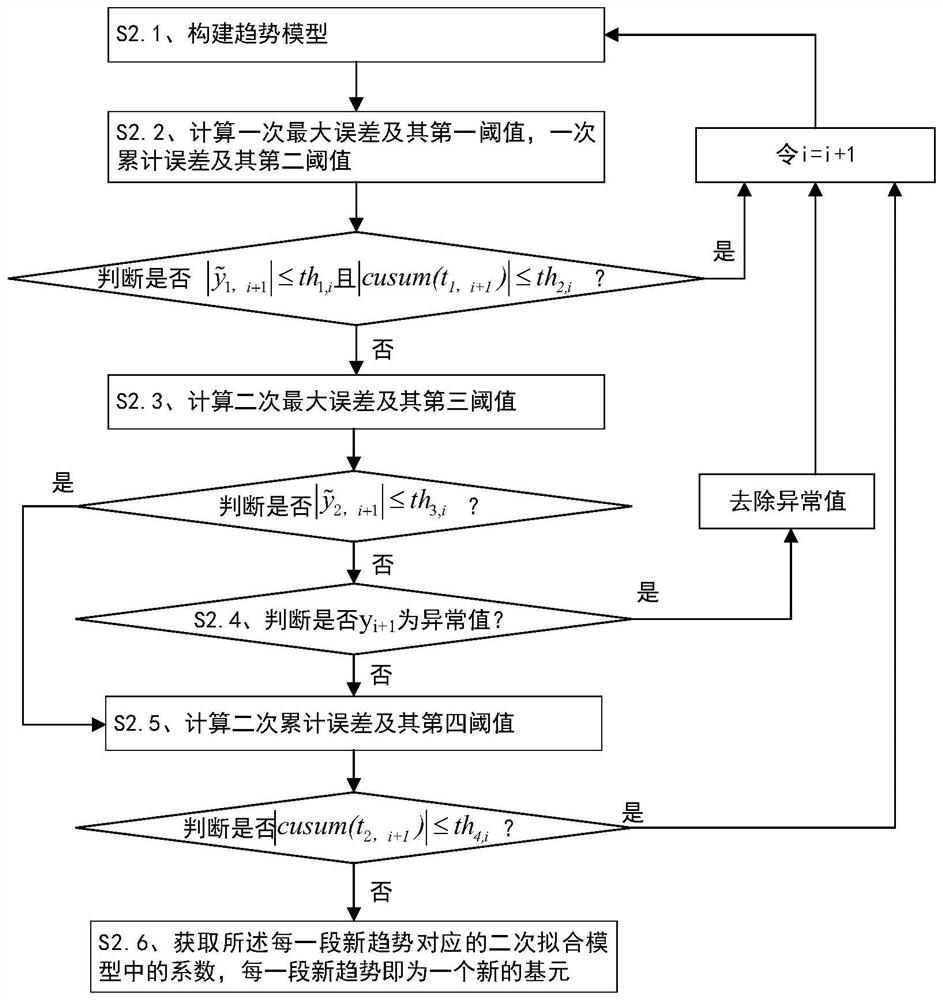

[0035] The embodiment of the present invention takes the zinc hydrometallurgy roasting process of a certain smelter as the background, and the process flow chart is as follows figure 1 shown. During the roasting process, the zinc concentrate particles are mixed evenly by the disc feeder and then blown into the fluidized roasting furnace through the conveyor belt. The blown air fully contacts and reacts with the zinc concentrate. When the wind speed reaches a certain speed, the zinc concentrate particles will be suspended to form a boiling layer. The state of the boiling layer is the main factor affecting the furnace ore of the roaster, and the state of the boiling layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com