A kind of preparation method of high magnetic permeability iron-based nanocrystalline soft magnetic alloy magnetic core

A technology of iron-based nanocrystals and soft magnetic alloys, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, and magnetic materials. Effects of reduced magnetic anisotropy, high effective permeability, and high remanence ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

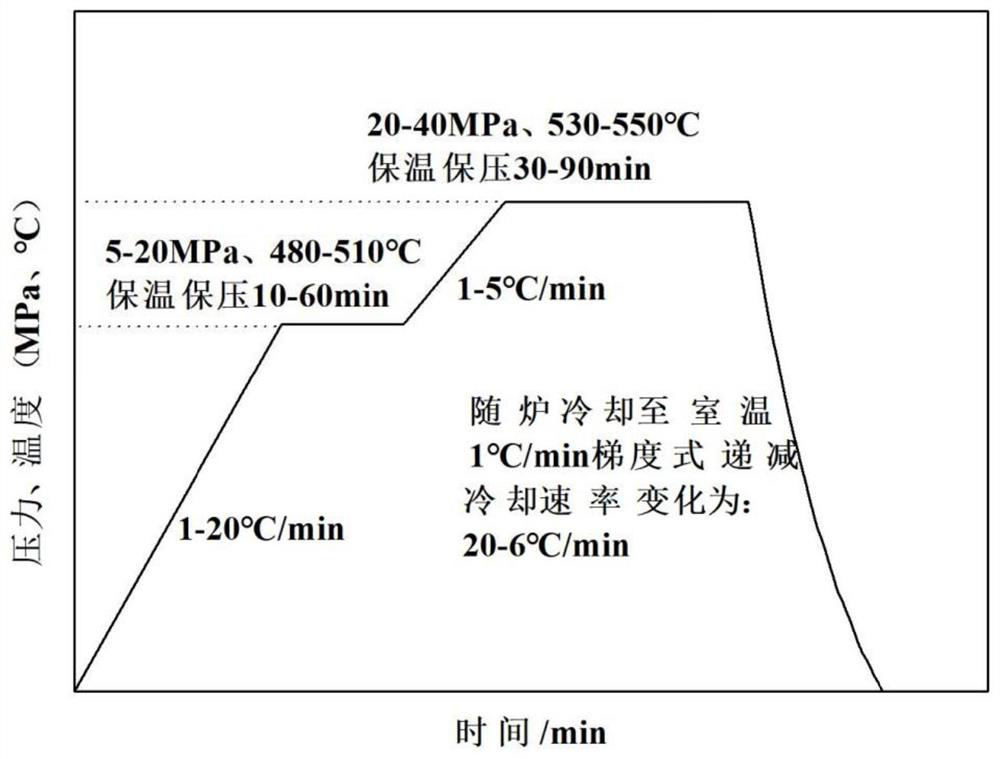

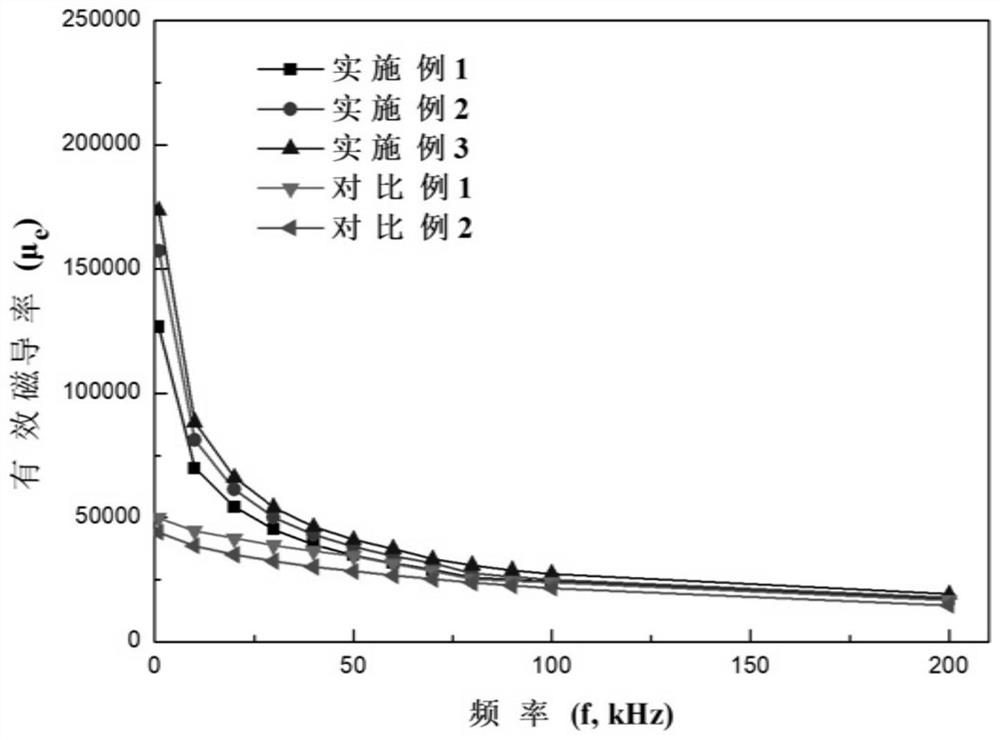

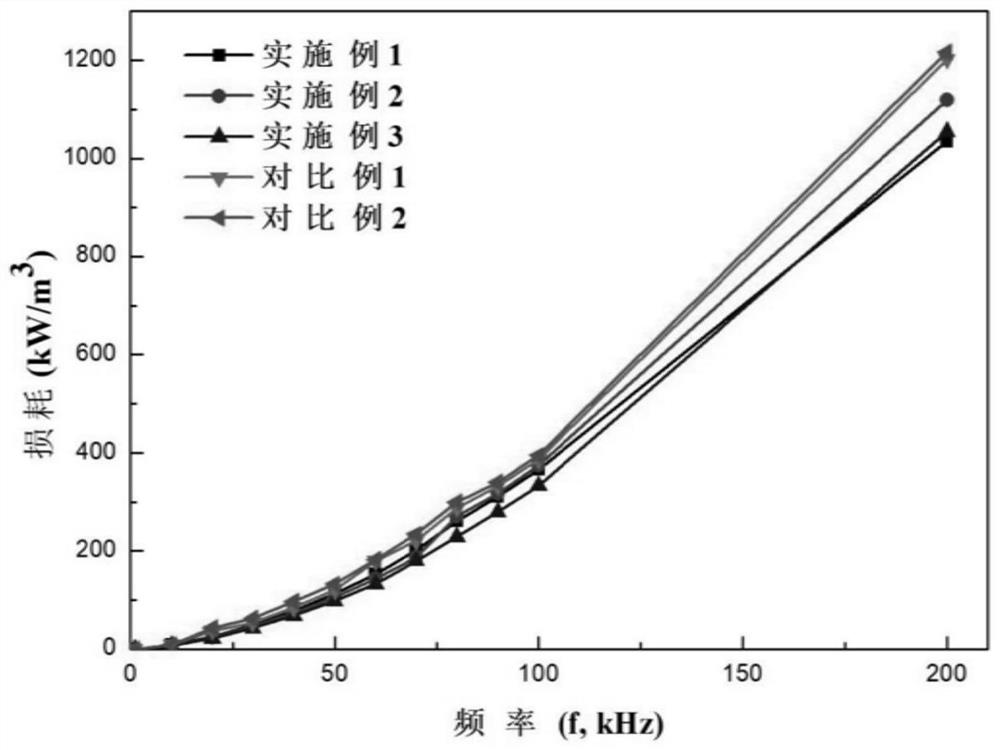

[0028] An embodiment of the method for preparing a high-permeability iron-based nanocrystalline soft magnetic alloy magnetic core according to the present invention, the preparation method in this embodiment includes the following steps:

[0029] will Fe 73.5 Si 13.5 B 9 Cu 1 Nb 3 Amorphous strip (atomic percentage), wound into a magnetic core, open the cavity, place the magnetic core in the cavity, close the furnace body, pump it to a vacuum state, and set the heat treatment process as follows: at a heating rate of 20°C / min from The room temperature was raised to 480°C, and high-purity Ar was charged into the furnace cavity at the same time. At the same time, the pressure was input to the magnetic core through Ar, and the control pressure was 15MPa. The magnetic core was kept at 480°C and 15MPa for 30 minutes. The temperature rises to 530°C at a heating rate of 2°C / min. At this time, the pressure rises to 30MPa. The magnetic core is kept at 530°C and 30Mpa for 60 minutes,...

Embodiment 2

[0031] An embodiment of the method for preparing a high-permeability iron-based nanocrystalline soft magnetic alloy magnetic core according to the present invention, the preparation method in this embodiment includes the following steps:

[0032] will Fe 73.5 Si 13.5 B 9 Cu 1 Nb 3 Amorphous strip (atomic percentage), wound into a magnetic core, open the cavity, place the magnetic core in the cavity, close the furnace body, evacuate to a vacuum state, and set the heat treatment process as follows: at a heating rate of 20°C / min from The room temperature was raised to 510 °C, and high-purity Ar was charged into the furnace cavity at the same time. At the same time, the pressure was input to the magnetic core through Ar, and the control pressure was 15MPa. The magnetic core was kept at 510 °C and 15MPa for 30 minutes. The temperature rises to 540°C at a heating rate of 2°C / min. At this time, the pressure rises to 30MPa. The magnetic core is kept at 540°C and 30MPa for 60 minut...

Embodiment 3

[0034] An embodiment of the method for preparing a high-permeability iron-based nanocrystalline soft magnetic alloy magnetic core according to the present invention, the preparation method in this embodiment includes the following steps:

[0035] will Fe 73.5 Si 13.5 B 9 Cu 1 Nb 3 Amorphous strip (atomic percentage), wound into a magnetic core, open the cavity, place the magnetic core in the cavity, close the furnace body, evacuate to a vacuum state, and set the heat treatment process as follows: at a heating rate of 20°C / min from The room temperature was raised to 510 °C, and high-purity Ar was charged into the furnace cavity at the same time. At the same time, the pressure was input to the magnetic core through Ar, and the control pressure was 15MPa. The magnetic core was kept at 510 °C and 15MPa for 30 minutes. The temperature rises to 550°C at a heating rate of 1°C / min. At this time, the pressure rises to 30MPa. The magnetic core is kept at 550°C and 30MPa for 60 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com