Method for improving performance of NiZn ferrite film prepared by rotary spraying

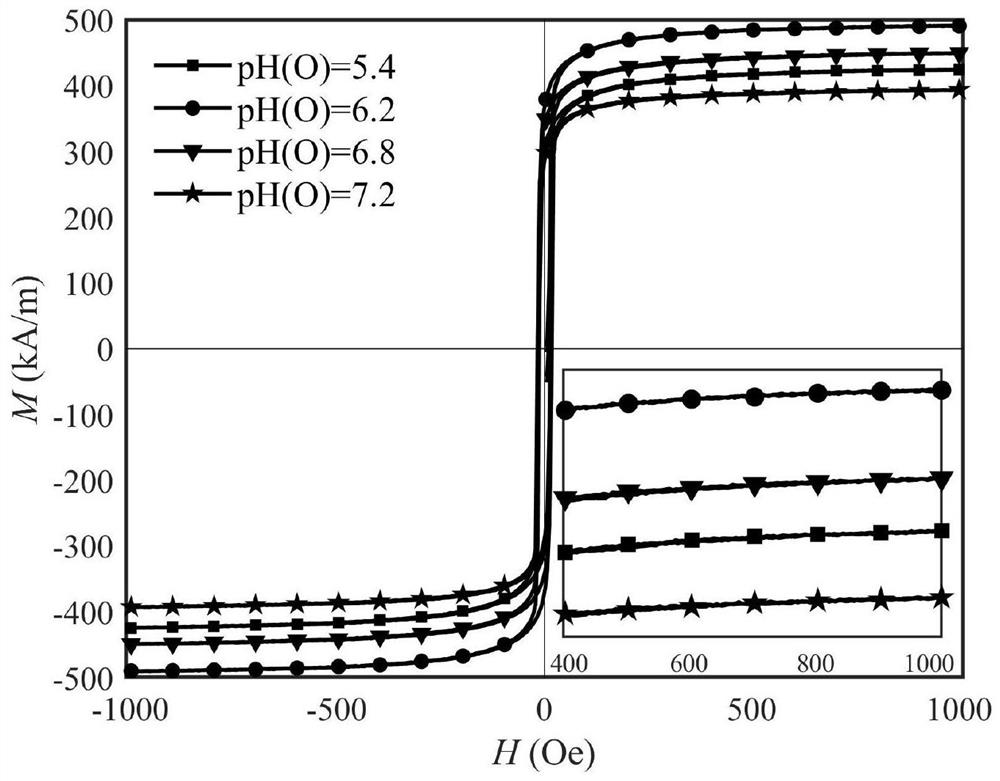

A technology of ferrite thin film and rotary spraying, which is applied to the device and coating of surface coating liquid, which can solve the problems of low magnetic permeability and saturation magnetization, high iron content of NiZn ferrite thin film, and film formation. Instability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

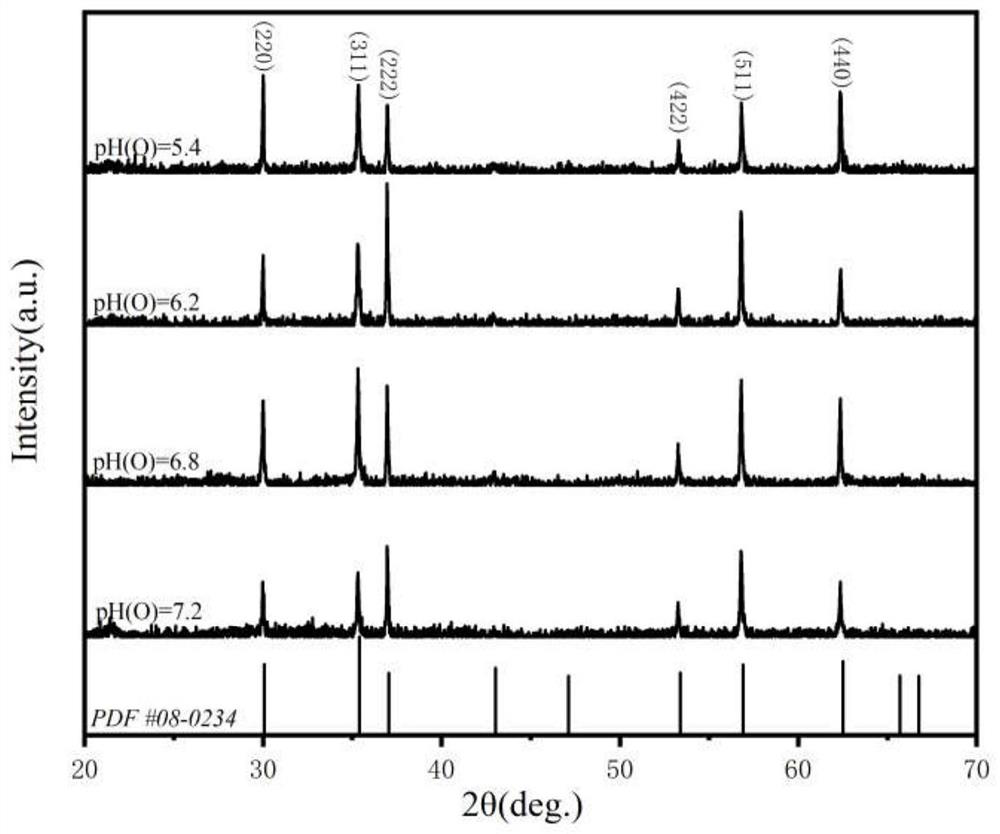

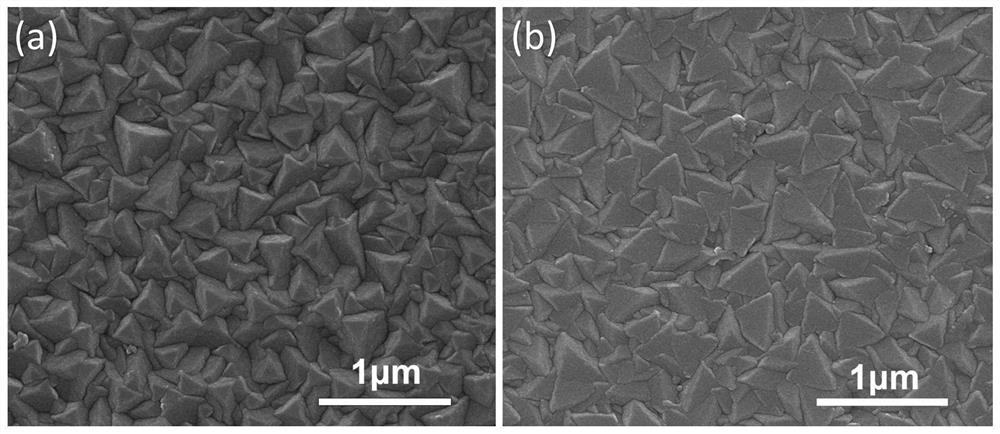

[0035] A method for improving the performance of NiZn ferrite film prepared by spin spraying, specifically comprising the following steps:

[0036] Step 1. Substrate preparation: wash the 0.2mm glass substrate twice with absolute ethanol, and let it dry naturally;

[0037] Step 2, preparation of oxidation reaction solution and reduction reaction solution: add soluble ferrous chloride, nickel chloride hexahydrate, and zinc chloride into 1L deionized water, stir and mix evenly to obtain a reduction reaction solution, in the reduction reaction solution, chlorinate The concentration of ferrous iron is 10.8mmol / L, the concentration of nickel chloride hexahydrate is 2mmol / L, and the concentration of zinc chloride is 0.6mmol / L; add sodium nitrite, sodium acetate, and acetic acid into 1L deionized water, stir and mix Uniformly, obtain oxidation reaction liquid, in oxidation reaction liquid, the concentration of sodium nitrite is 2.2mmol / L, and the concentration of sodium acetate is 18...

Embodiment 2

[0042] Compared with Example 1, the present embodiment differs in that the amount of acetic acid added when preparing the oxidation reaction solution in step 2 is 0.6 mL (the volume fraction of acetic acid is 0.06%), and the pH value of the oxidation solution is pH (0 ) = 6.2.

Embodiment 3

[0044] Compared with Example 1, this embodiment differs in that the amount of acetic acid added when preparing the oxidation reaction solution in step 2 is 0.2 mL (the volume fraction of acetic acid is 0.02%), and the pH value of the oxidation solution is pH (0 ) = 6.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com