Light agricultural earth boring machine

A kind of earth drilling machine, light technology, applied in agriculture, application, excavation/covering trenches, etc., can solve the problem of reducing the utilization rate of agricultural production operations, drilling hole diameter, hole direction irregularity, difficult to accurately control the drilling direction, etc. problem, to achieve the effect of high utilization rate of mechanical parts, increased drilling depth range, and improved application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The light-duty agricultural earth-boring machine disclosed in this embodiment is composed of two parts: a host machine and a drilling tool that cooperate with each other;

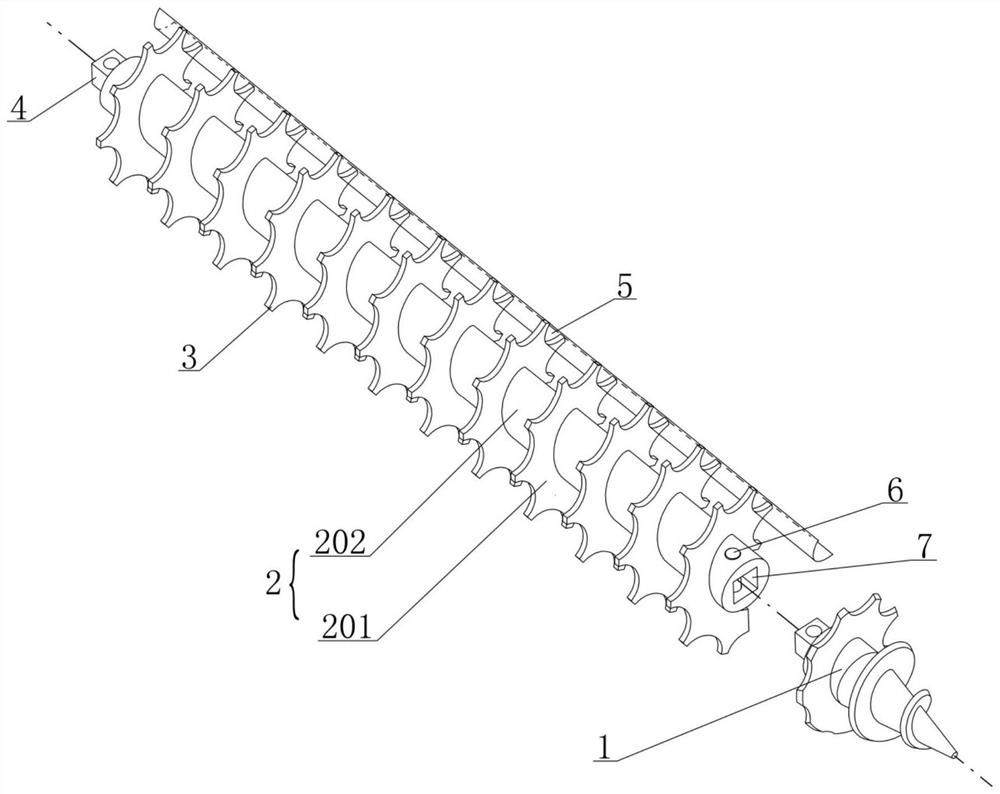

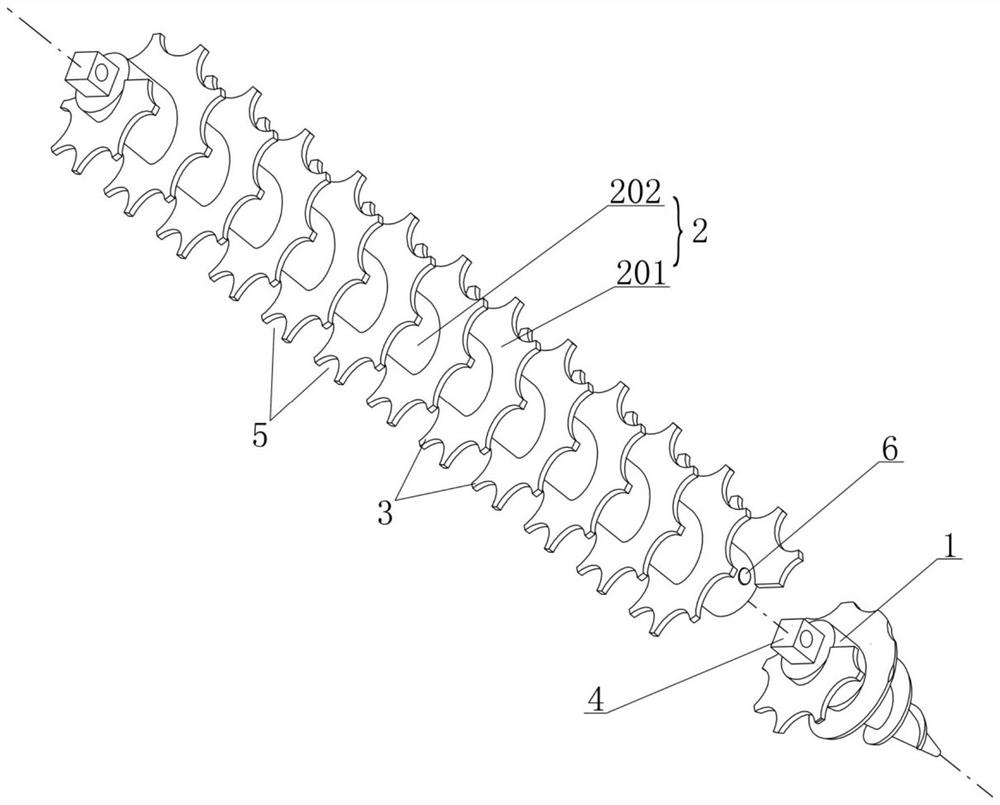

[0029] Among them, see figure 1 , 2 As shown, the drilling tool includes a drill bit 1 and a drill rod 2 that can be combined and connected. There are multiple drill rods 2 that can be connected end to end; The sheet 201 is wound and fixed on the outside of the core rod 202; the helical sheet 201 is surrounded by a number of axial grooves 5 that are equiangularly distributed and extend axially along the drill pipe 2, and the outer edge of the helical sheet 201 is in the adjacent axial groove. The part between 5 is tooth 3;

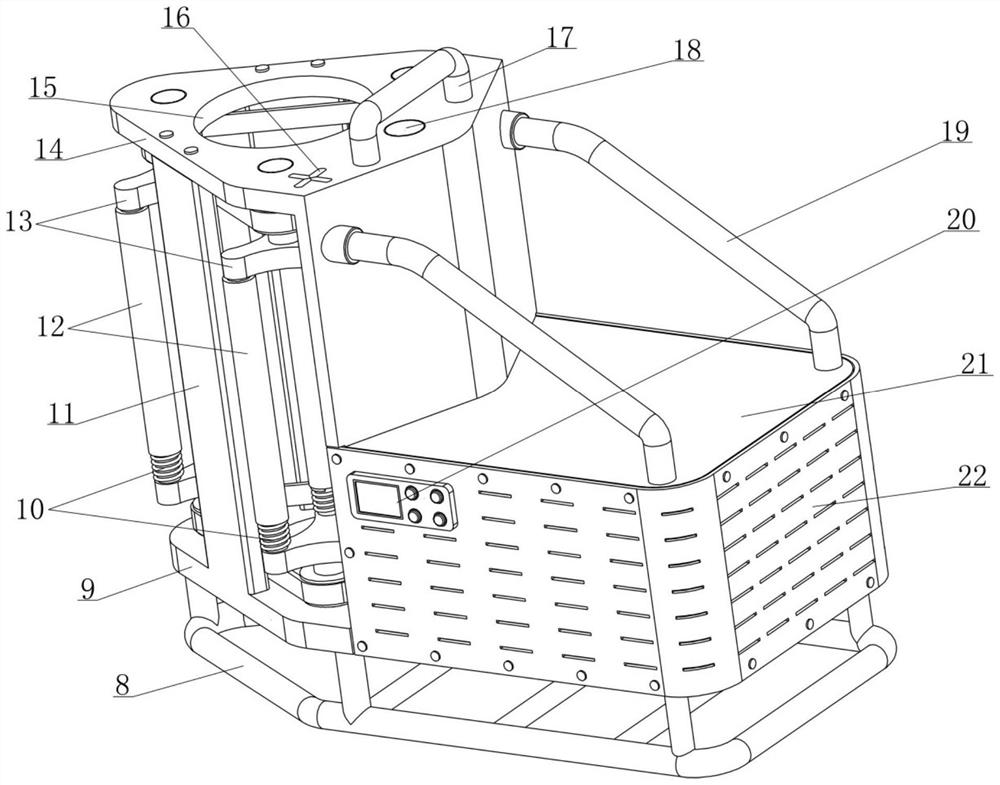

[0030] Among them, see image 3 , 4 , 5 and 6, the main frame includes a frame 8, the frame 8 is provided with a top plate 14 and a base plate 9 distributed up and down, and the frame 8 is laid flat on the ground and the base plate 9 has a ground clearance. The top plate 14 ...

Embodiment 2

[0051] see Image 6 As shown, during the drilling operation of the light-duty agricultural earth-boring machine disclosed in the aforementioned embodiments, the spiral piece 201 will transport the earth material produced in the borehole to the ground. Generally, it will not affect the normal operation of the drilling operation. If the drilling depth is deep and the soil material produced is large, the soil material needs to be transferred to avoid the soil material gathering above the hole and affecting the drilling efficiency. The operator can The soil material produced by drilling is transferred by tools such as shovels to avoid the accumulation of soil material above the hole, but this operation method is cumbersome, time-consuming and laborious. For this reason, the present embodiment has further improvements on the basis of the structure of the light agricultural earth-boring machine disclosed in embodiment 1, and the specific structure is:

[0052] see Figure 9 , 10 ...

Embodiment 3

[0056] see Image 6 As shown, in the structure adopted by the light-duty agricultural earth-boring machine disclosed in the foregoing embodiments, the helical piece 201 is provided with an axial groove 5 so that its outer end is formed with teeth 3 distributed at intervals. This kind of special structure will weaken its upward conveying ability to soil materials, but because most of the soil in the farmland has poor fluidity, in addition, the rotation frame 13, driving roller 12, axial groove 5, teeth 3 and other parts can be adjusted during implementation. Relative positional relationship, quantity, specific shape and size and other parameters are reasonably adjusted to make up for the aforementioned lack of poor conveying capacity, thereby ensuring that the spiral blade 201 can convey the soil material generated during the drilling process to the ground above the ground. At the same time, this embodiment has a further improvement on the basis of the structure of the light-du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com