Low-temperature curing process for refrigerated and pre-conditioning meat product

A technology of low-temperature curing and meat products, which is applied in the preservation of meat/fish, preservation of meat/fish by freezing/cooling, preservation of meat/fish by radiation/electrical treatment, etc., can solve the problems of evaluating the quality of pre-conditioned meat products, etc. Achieve the effect of realizing industrialized production and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

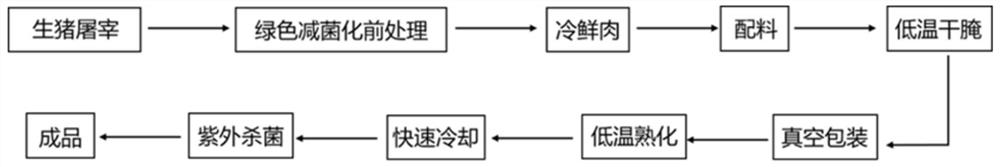

[0030] A low-temperature curing process for refrigerated pre-conditioned meat products, comprising the steps of:

[0031] (1) Raw meat acquisition and pre-treatment: the raw pork pre-treated with green reduction bacteria, after sorting, cutting and reshaping, sliced and refrigerated at 2°C to obtain chilled fresh meat for later use;

[0032] (2) Compound spice powder: use an electronic balance to accurately weigh 1 part of dried red pepper, 1 part of dried peppercorns, 1 part of star anise, 1 part of fragrant leaves, 1 part of turmeric, 1 part of cinnamon, 1 part of cumin and 5 parts of food salt, crush the spices, pass through an 80-mesh sieve, stir evenly with edible salt, store in a refrigerator at 2°C, and prepare the compound spice powder for later use;

[0033] (3) Low-temperature dry pickling: Take 70 parts of chilled fresh meat and 7 parts of pre-cooled seasoning powder at 2°C in a pre-cooled stainless steel basin with a diameter of 50 cm and a height of 40 cm, and f...

Embodiment 2

[0039] A low-temperature curing process for refrigerated pre-conditioned meat products, comprising the steps of:

[0040] (1) Acquisition and pretreatment of raw meat: raw pork pretreated by green reduction, after sorting, cutting and reshaping, sliced and refrigerated at 3°C to obtain chilled fresh meat for later use;

[0041] (2) Compound spice powder: use an electronic balance to accurately weigh 1.2 parts of dried red pepper, 1.2 parts of dried peppercorns, 1.2 parts of star anise, 1.2 parts of fragrant leaves, 1.2 parts of turmeric, 1.2 parts of cinnamon, 1.2 parts of cumin and 6 parts of food Salt, crush the spices, pass through an 80-mesh sieve, stir evenly with edible salt, store in a refrigerator at 3°C, and prepare the compound spice powder for later use;

[0042] (3) Low-temperature dry pickling: Take 90 parts of cold fresh meat and 9 parts of pre-cooled seasoning powder in a pre-cooled stainless steel basin with a diameter of 50 cm and a height of 40 cm under l...

Embodiment 3

[0048] A low-temperature curing process for refrigerated pre-conditioned meat products, comprising the steps of:

[0049] (1) Acquisition and pretreatment of raw meat: the raw pork that has been pretreated with green bacteria reduction, after sorting, cutting, and reshaping, slices and refrigerates at 0°C to obtain chilled fresh meat for later use;

[0050](2) Compound spice powder: use an electronic balance to accurately weigh 1.5 parts of dried red pepper, 1.5 parts of dried peppercorns, 1.5 parts of star anise, 1.5 parts of fragrant leaves, 1.5 parts of turmeric, 1.5 parts of cinnamon, 1.5 parts of cumin and 8 parts of food salt, crush the spices, pass through an 80-mesh sieve, stir evenly with edible salt, store in a refrigerator at 0°C, and prepare compound spice powder for later use;

[0051] (3) Low-temperature dry pickling: Take 110 parts of chilled fresh meat and 11 parts of pre-cooled seasoning powder in a pre-cooled stainless steel basin with a diameter of 50 cm and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com