8N electronic-grade high-purity ammonia rectification system and quality control method thereof

A quality control method and rectification system technology, applied in the 8N electronic grade high-purity ammonia rectification system and its quality control field, can solve problems such as inability to stably produce and control rectification process parameters, to ensure high purity, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

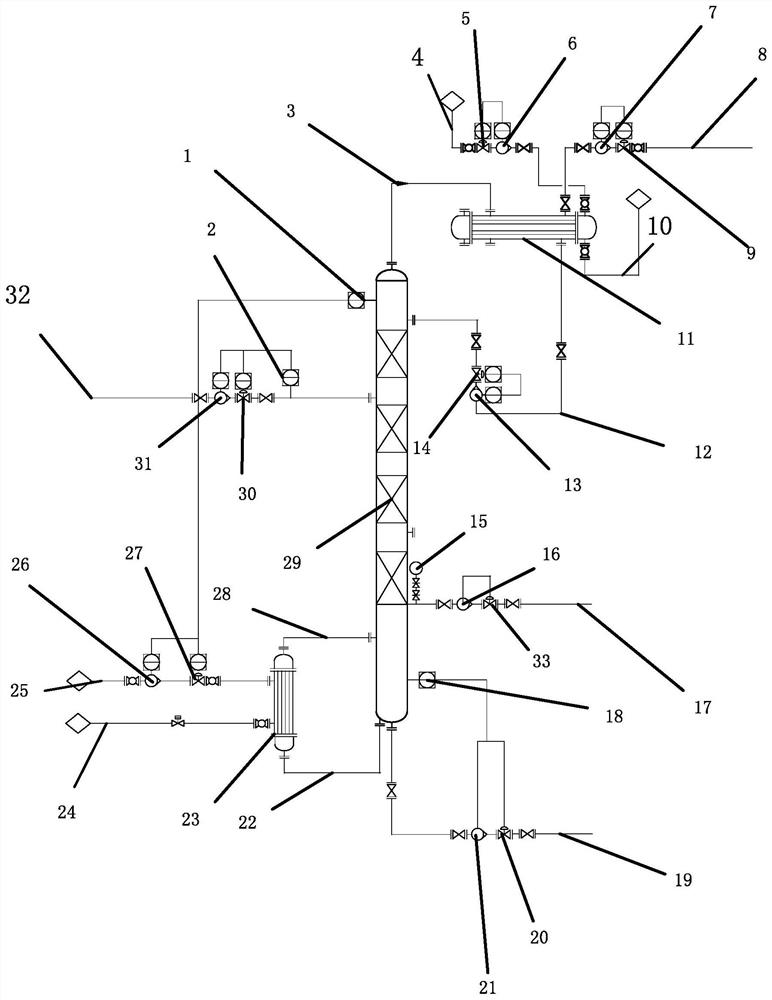

[0021] Such as figure 1 Shown, the technical solution of the present invention is a kind of 8N electronic grade high-purity ammonia rectification system, and it comprises rectification tower 29, reboiler, condenser 11, vaporizer, feed pipe 32, tower top exhaust pipe 8, The product collection outlet pipe 17 and the tower kettle row pipe 19 are characterized in that a reboil inlet pipe 22 and a reboil outlet pipe 2823 are connected between the reboiler and the rectifying tower 29, and a reboiler outlet pipe 2823 is connected to the reboiler. A hot water inlet pipe 24 and a hot water outlet pipe 25, a condensation inlet pipe 3 and a condensation outlet pipe 12 are connected between the condenser 11 and the rectification tower 29, and a cold water inlet pipe 10 and a cold water outlet pipe 4 are connected on the condenser 11. The waste discharge pipe 8 at the top of the tower is connected to the exhaust outlet of the condenser 11, the feed pipe 32, the product collection outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com