Anti-falling rotary transfer robot

A handling robot, rotating technology, applied in the field of handling robots, can solve the problems of affecting the appearance effect, object damage, etc., and achieve the effect of easy handling, accelerated wear and tear, and enhanced safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

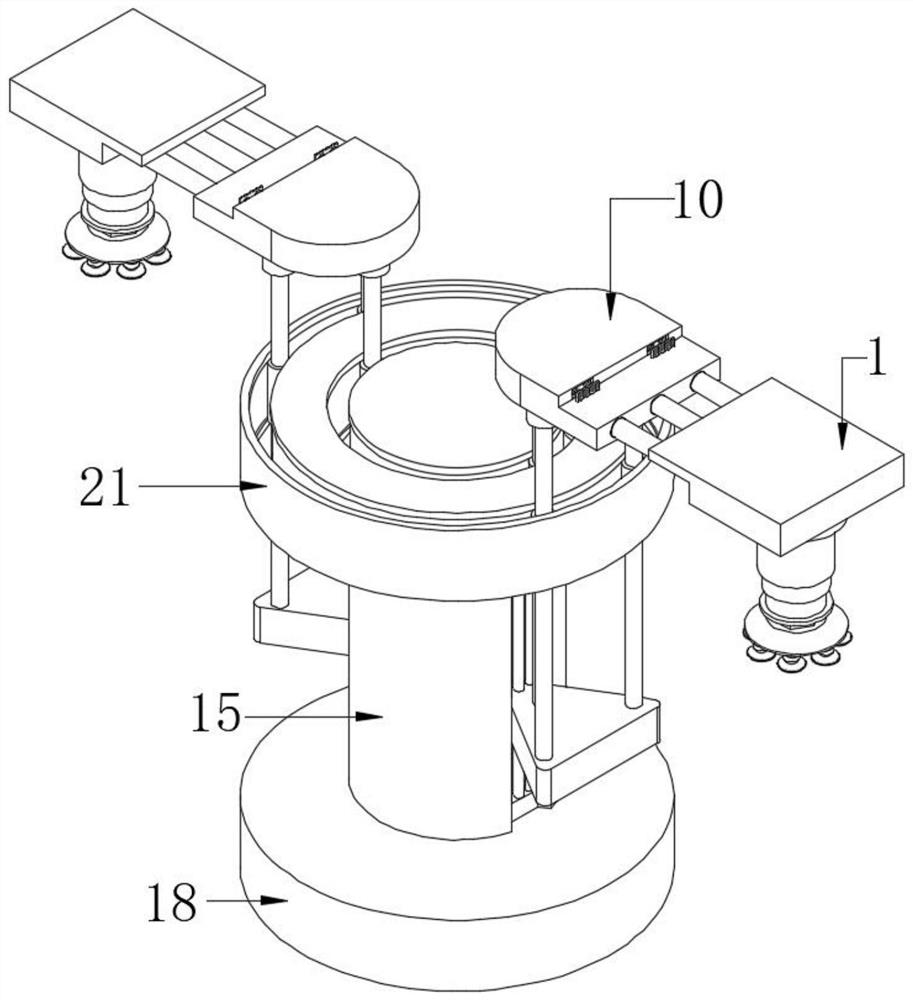

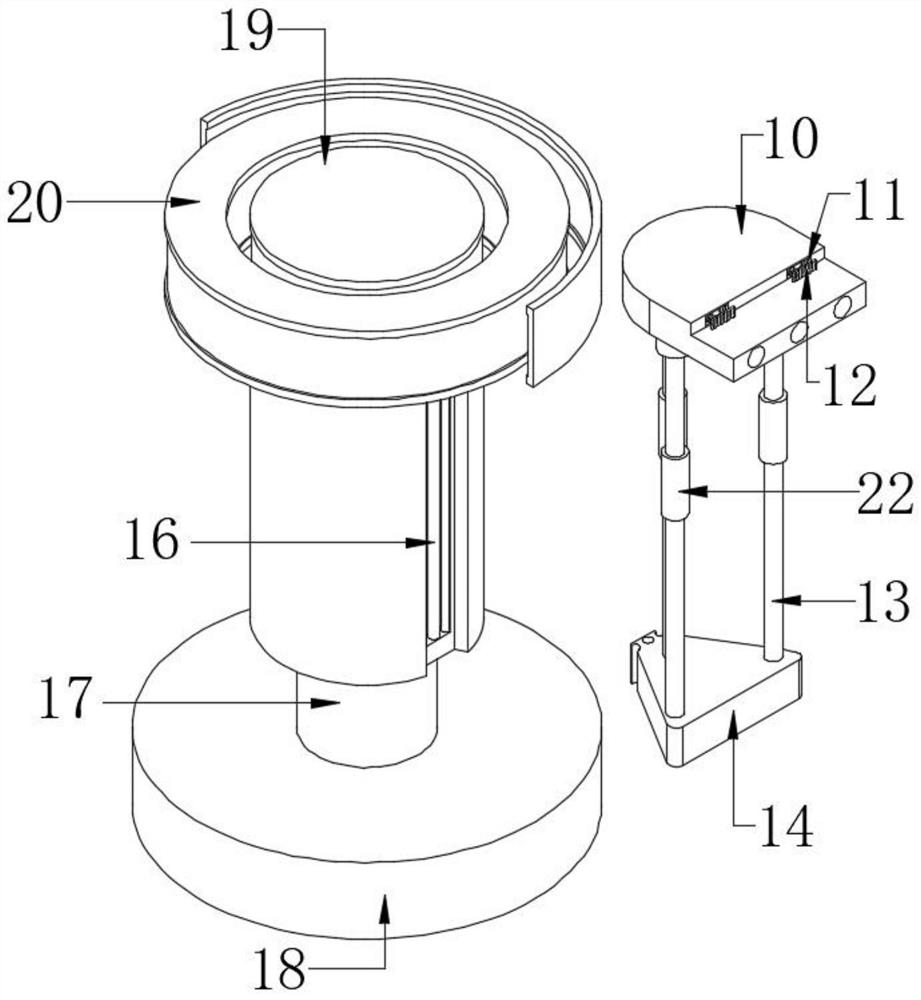

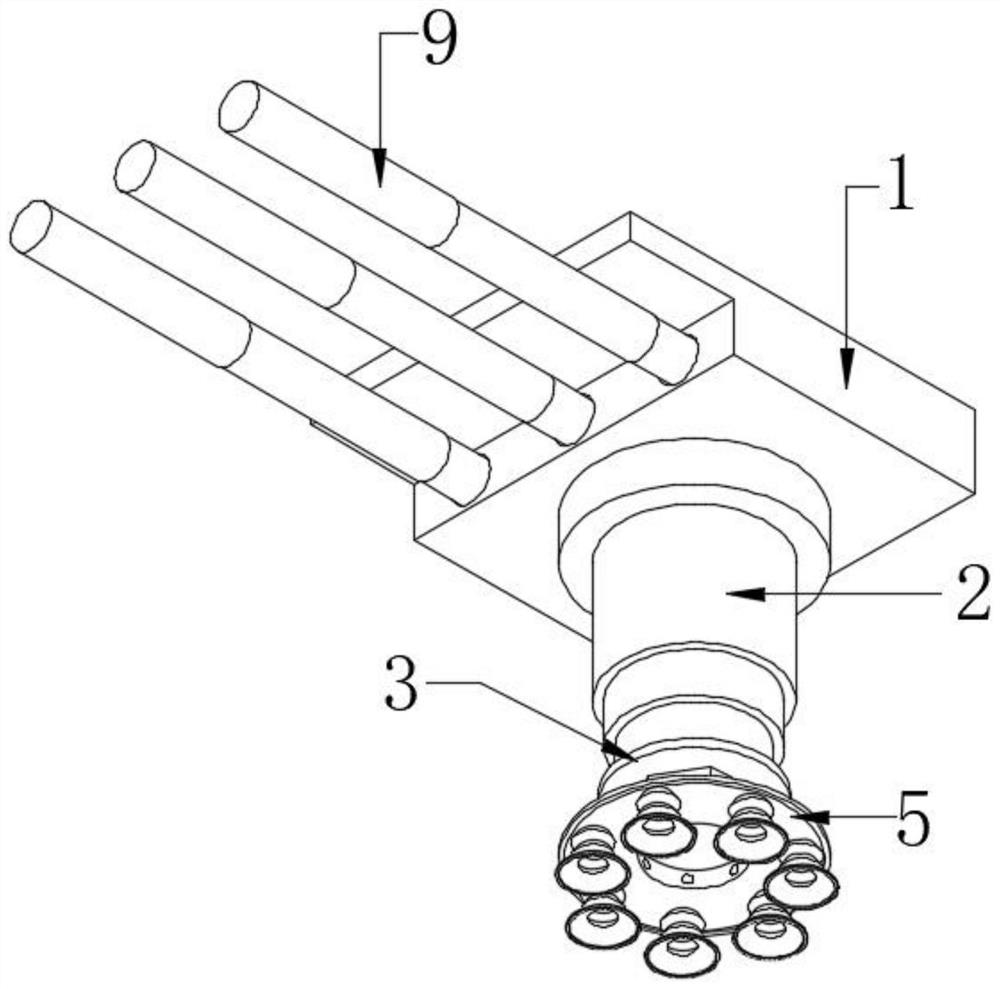

[0026] refer to Figure 1-4 , a rotary transfer robot that can prevent falling off, including an extension platform 1, the lower outer wall of the extension platform 1 is connected with a hydraulic rod 2 through bolts, and the other end of the hydraulic rod 2 is connected with a connecting plate 3 through bolts, and the connecting plate 3 The lower outer wall of the airflow control valve 4 is connected with the airflow control valve 4 through bolts, and the other end of the airflow control valve 4 is connected with the lifting plate 5 through bolts. The bottom of the lifting plate 5 is provided with a plurality of airflow holes, and the outer walls of the multiple airflow holes are The compression sleeve 6 is connected by bolts, and the bottom of the compression sleeve 6 is connected with a suction cup 7 by bolts. The outer walls of the suction cups 7 are provided with circular grooves, and the inner walls of the circular grooves are connected with silica gel pads 8 by bolts. ...

Embodiment 2

[0035] refer to Figure 5, a rotary handling robot that can prevent falling off. Compared with Embodiment 1, this embodiment also includes a base 23 under the chassis 18. The lower outer wall of the chassis 18 and the upper outer wall of the base 23 are provided with multiple a square slot, and a damper 24 is connected by bolts between the upper and lower square slots.

[0036] When in use, according to the position feedback signal of the object to be transported to the center plate 10, the triangular tray 14 is driven by the electric slide rail 16 to adjust the height of the center plate 10, and then the three telescopic rods 9 are stretched to adjust the extension table 1 and the center plate 10 After the stretching platform 1 reaches the top of the object to be transported, the hydraulic rod 2 will be stretched, and the suction cup 7 will be in contact with the surface of the object. During the continuous extrusion process of the hydraulic rod 2, the compression sleeve 6 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com