Device and method for intensifying aeration by utilizing fine bubbles generated by hydraulic shearing

A technology of fine air bubbles and hydraulic shearing, applied in chemical instruments and methods, biological treatment devices, water aeration, etc., can solve problems such as easy blockage of aeration system, low oxygenation efficiency, low oxygen utilization rate, etc., to achieve Increase dissolved oxygen rate and oxygen utilization rate, low power consumption, and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

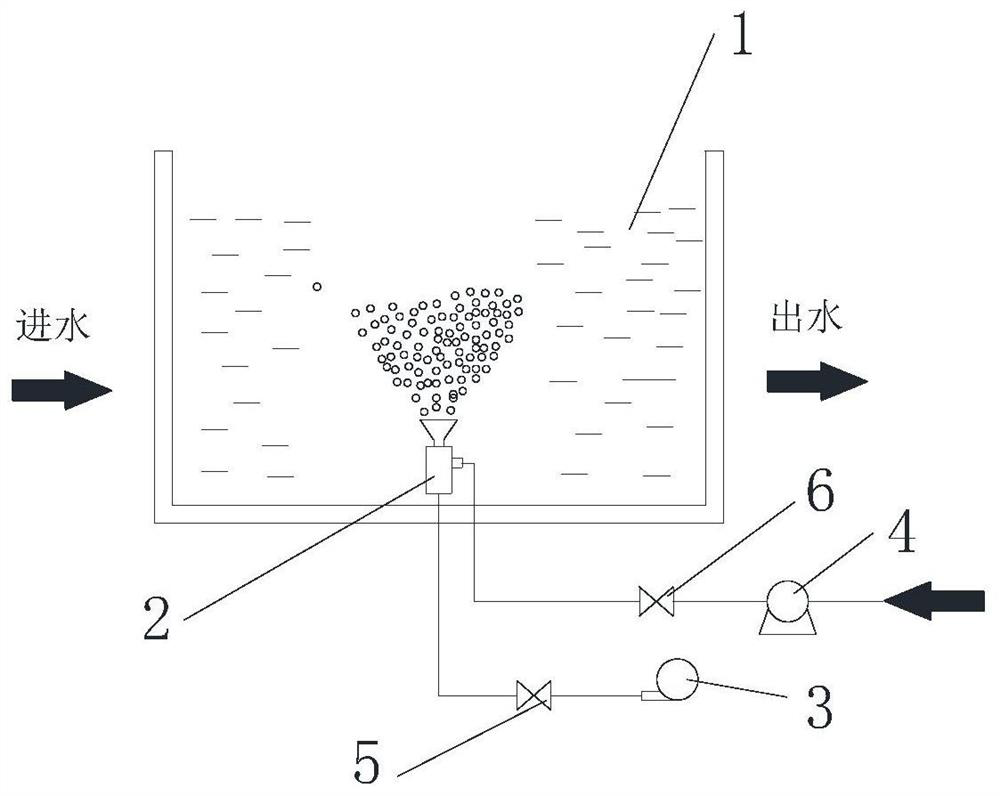

[0039] figure 1 It is the device of the present invention that utilizes hydraulic shearing to generate micro-bubbles to enhance aeration, and is used in the aeration tank 1 for biological treatment of wastewater. The device for enhancing aeration includes an aeration core arranged at the bottom of the aeration tank 1 The tube 2 is connected with the aeration core tube 2 through a pipeline, and the blower 3 and the booster pump 4 are placed outside the aeration tank 1 .

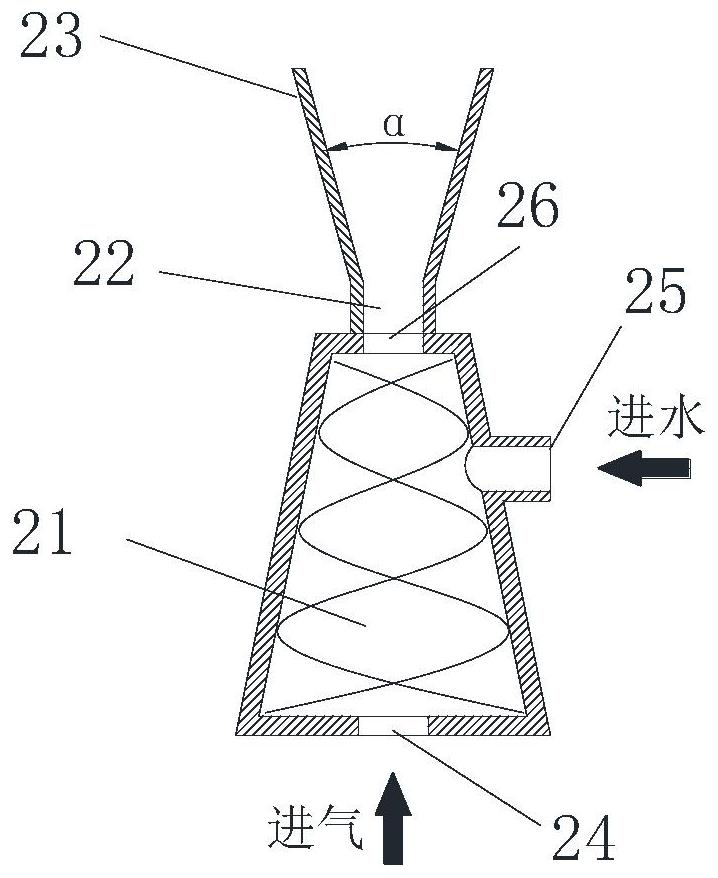

[0040] Among them, such as figure 2As shown, the aeration core tube 2 includes a swirl chamber section 21, a throat section 22 and a diffuser section 23 connected in sequence; the swirl chamber section 21 has a spiral cavity structure inside, and the swirl chamber The side wall of chamber section 21 is provided with one or more liquid inlets 25, and the direction of described liquid inlet 25 is tangent to the side wall of described swirl chamber section 21, and the bottom of described swirl chamber section 2...

Embodiment 2

[0061] The device and method described in Example 1 are used to generate micro-bubbles to strengthen aeration by hydraulic shearing, and the aeration is strengthened under different working conditions where the water depth of the aeration tank is 2-4m, 4-6m and 6-8m respectively, and the treatment sewage. The aeration core tube includes a liquid inlet, and the installation direction of the aeration core tube is that the outlet of the diffusion section is upward, and the aeration direction is upward aeration. The specific operating data and achieved effects for different water depths of aeration tanks are shown in the table below.

[0062]

[0063] Under the above operating conditions, the oxygen utilization rate of aeration is in the range of 20%-25%, and on the premise of ensuring that the dissolved oxygen concentration in the aeration tank is 2-5mg / L, the hydraulic retention time is compared with that without the above-mentioned hydraulic retention time. The sheared blas...

Embodiment 3

[0065] Adopt the device described in embodiment 1 to utilize hydraulic shearing to produce fine air bubbles to strengthen aeration, such as Figure 5 As shown, the swirl chamber section of the aeration core pipe is cylindrical, including 3 liquid inlets, and distributed at equal intervals along the section of the swirl chamber section, that is, the angle formed by adjacent liquid inlets is 120° °, the liquid inlet is located at 3 / 4 of the height of the swirl chamber section. The water depth of the aeration tank is 2-4m, the diameter of the liquid inlet is 10mm, the diameter of the air inlet is 8mm, the diameter of the bubble outlet is 15mm, the height of the swirl chamber section is 20cm, the length of the throat section is 3cm, and the angle of the diffusion section is α is 20°.

[0066] Using the method described in Example 1, the booster pump provides liquid feed to the 3 liquid inlets of the aeration core pipe with a working pressure of 0.1Mpa, and the flow rate of each l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com