Sealing plugging material for electric power as well as preparation method and application thereof

A sealing plugging and electric power technology, which is applied in the field of electric power engineering, can solve problems such as poor expansion performance and high temperature resistance of sealing plugging materials, and achieve the effects of improving expansion performance, ensuring expansion uniformity, and inhibiting cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

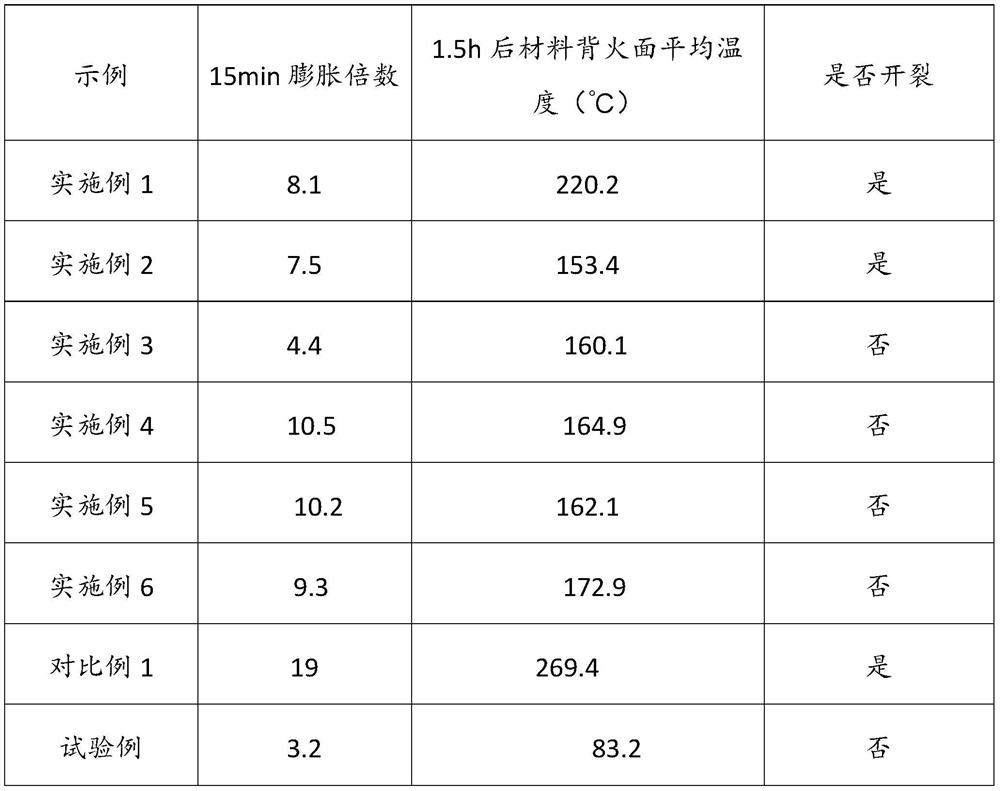

Examples

preparation example Construction

[0027] The present invention also provides a preparation method of the sealing and blocking material for electric power, comprising the following steps:

[0028] After the modified vermiculite, organic resin and reinforcing material are mixed evenly, the composite material is obtained by stirring and reacting at 170°C; the prepared composite material is ground and sieved, and the curing agent is added, mixed evenly, and placed in an oven at 180°C Inside, the cured sample was obtained.

[0029] The vermiculite modification method is to fully stir vermiculite and water in a container at a mass ratio of 1:10, add sodium chloride or hydrochloric acid, place it in a water bath at 70-75°C and stir for 2 hours, cool and suction filter, and use deionized Wash it with water several times, then activate it at 110°C for 2 hours with an electric constant temperature blast drying oven, grind it, and sieve it to make a modified vermiculite.

[0030] The modified vermiculite expands at high...

Embodiment 1

[0036] This embodiment provides a sealing and blocking material for electric power, which includes 85% phenolic resin, 8% unexpanded vermiculite, 5% 1, 4 butanediol, 2% cellulose fibers.

[0037] The preparation method of the above-mentioned sealing and blocking material for electric power comprises the following steps,

[0038] After the unexpanded vermiculite is sieved through 250 mesh, after being modified by HCL / NaCl, it is ground to a specific surface area of 350g / cm 2 The powder, modified vermiculite, organic resin and reinforcing material are mixed evenly, and then stirred and reacted at 170°C to obtain a composite material; the prepared composite material is ground and sieved, added a curing agent, mixed evenly, and placed in In an oven at 180°C, the cured sample was obtained.

Embodiment 2

[0040] This embodiment provides a sealing and blocking material for electric power, which includes 85% phenolic resin, 8% unexpanded vermiculite, 5% 1, 4 butanediol, 2% cellulose fibers.

[0041] The preparation method of the above-mentioned sealing and blocking material for electric power comprises the following steps,

[0042] Sieve the unexpanded vermiculite through 250 mesh, modify it with HCL / NaCl, expand it at 800°C, and grind it to a specific surface area of 350Kg / m2 with an expansion factor of 10 times 2 The powder, modified vermiculite, organic resin and reinforcing material are mixed evenly, and then stirred and reacted at 170°C to obtain a composite material; the prepared composite material is ground and sieved, added a curing agent, mixed evenly, and placed in In an oven at 180°C, the cured sample was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com