Non-woven fabric rolling mechanism of mask machine and rolling method

A technology of non-woven fabric and rolling, which is applied in the field of non-woven rolling mechanism and rolling, which can solve the problems that dust is easy to stick on the pressure roller, affects the cleanliness of non-woven fabrics, and is inconvenient to use, so as to achieve convenience Effects of adjustment, cleanliness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

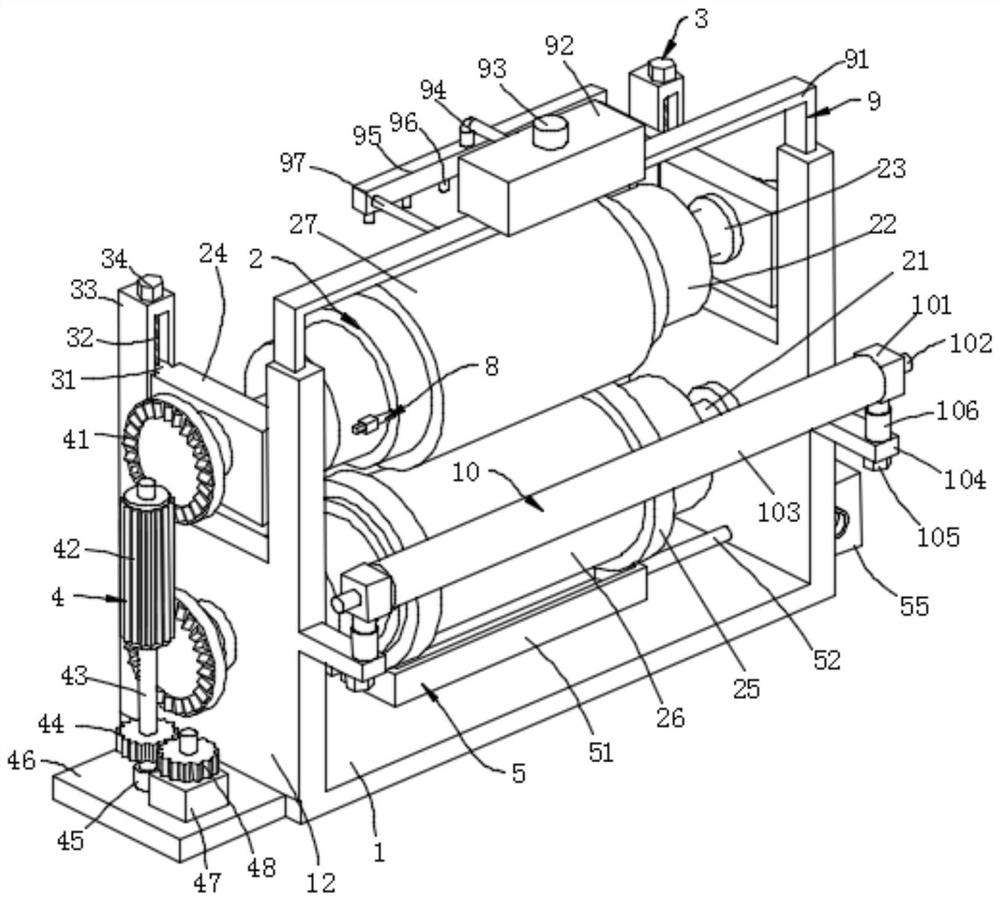

[0044] Example 1, please refer to Figure 1-2 And 7, this embodiment provides a technical solution: a non-woven fabric rolling mechanism of a mask machine, including a base 1, a rolling execution unit 2, a pressure roller spacing adjustment unit 3, a rolling power unit 4 and a pressure roller position adjustment unit 8;

[0045] Both sides of the surface of the base 1 are respectively provided with side plates 12 perpendicular to the surface of the base 1, and a rolling power unit 4 is installed on the side of one of the side plates 12;

[0046] The rolling execution unit 2 includes a rotating shaft 21, a mounting cylinder 22, a bearing 23, a movable mounting plate 24, a pressure roller 25, an annular groove 26 and an annular sleeve 27, and a bearing 23 is rotatably connected between the two side plates 12. The two ends of the rotating shaft 21, and the tops of the two side plates 12 are respectively equipped with two movable mounting plates 24 through the pressure roller spa...

Embodiment 2

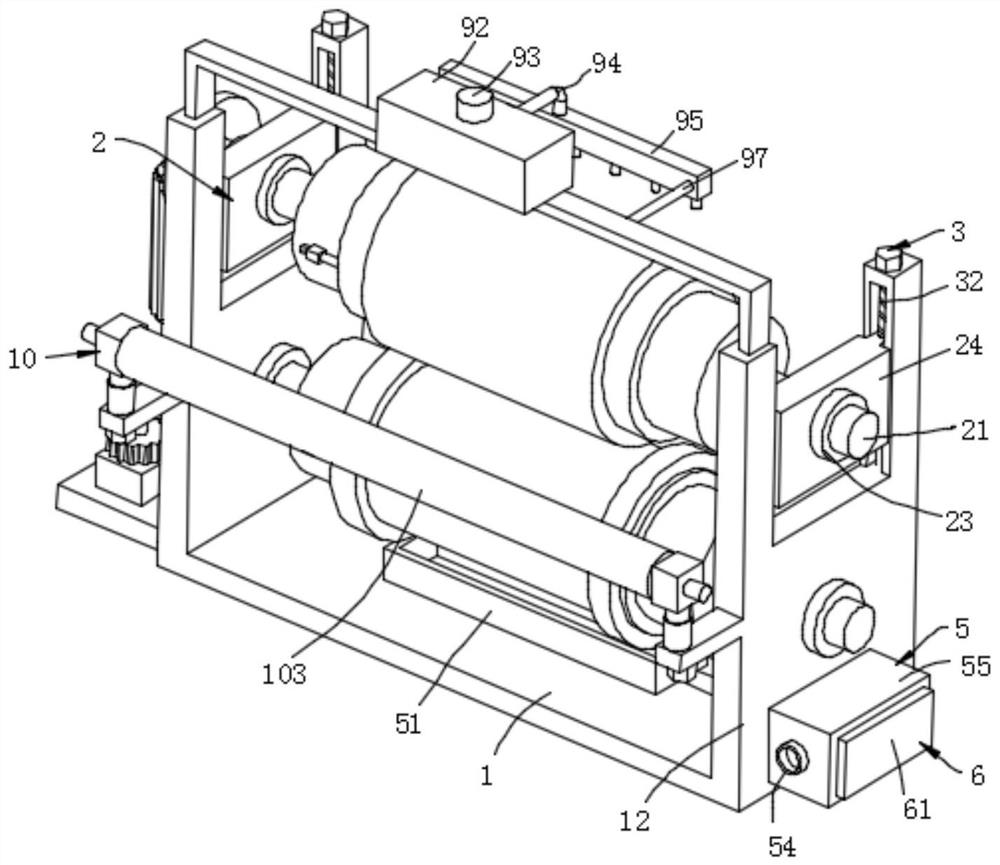

[0054] Example 2, please refer to figure 1 , 3 And 4, this embodiment provides a technical solution: a non-woven fabric rolling mechanism of a mask machine, the structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that it also includes a dust absorption unit 5, which absorbs dust The unit 5 includes a dust collection cover 51, a dust suction pipe 52, a separation box 53, an air outlet 54, an installation box 55, an air pump 56, an air supply pipe 57 and a partition 58, and is fixed on the outside of the side plate 12 away from the rolling power unit 4. Install box 55, be provided with dividing plate 58 in installing box 55, one side of dividing plate 58 is provided with separating box 53, the inlet of separating box 53 connects the air outlet of air pump 56 through air supply pipe 57, the air inlet of air pump 56 passes suction The dust pipe 52 is connected to the dust collection cover 51, the dust collection cover 51 is placed on the ba...

Embodiment 3

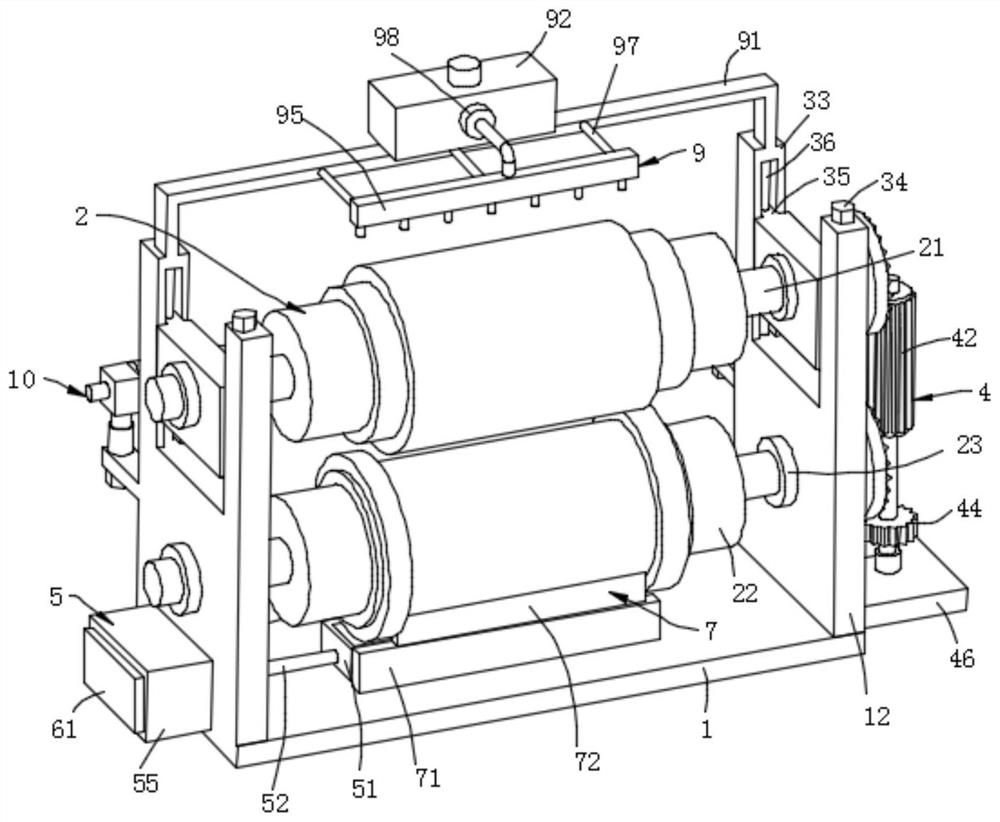

[0056] Embodiment three, please refer to Figure 3-5 , this embodiment provides a technical solution: a non-woven fabric rolling mechanism for a mask machine. It includes an end cover 61, a sealing ring 62, an inner sleeve 63, a flexible sealing sleeve 64, an installation frame 65, a filter screen 66 and a sealing strip 67. The side opening of the separation box 53 is provided with an end cover 61, and the end cover 61 is sleeved There is a sealing ring 62, and an inner sleeve 63 is provided on the side of the end cover 61, and a flexible sealing sleeve 64 is sleeved on the inner sleeve 63, and the inner sleeve 63 is fixed in one side opening of the separation box 53 through the flexible sealing sleeve 64, and the end cover A mounting frame 65 is arranged equidistantly inside the 61 , and a filter screen 66 is arranged in the mounting frame 65 , and a sealing strip 67 is arranged on the rear side of the mounting frame 65 located in the separation box 53 .

[0057] When the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com