Antibacterial garment cloth preparation system and preparation process

A technology for preparing systems and fabrics, which is applied in the processing of textile material equipment configuration, textile processing machine accessories, textile material processing, etc., can solve the problems of poor durability and easy falling off, and achieve the effect of good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

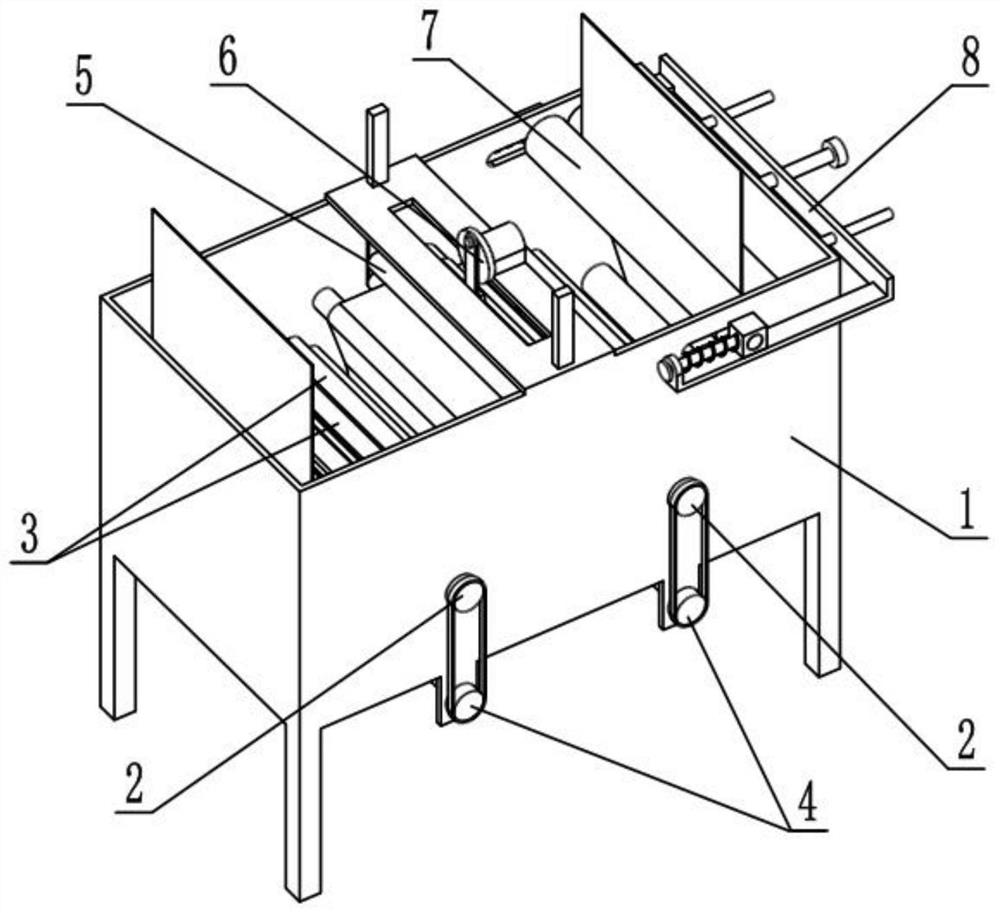

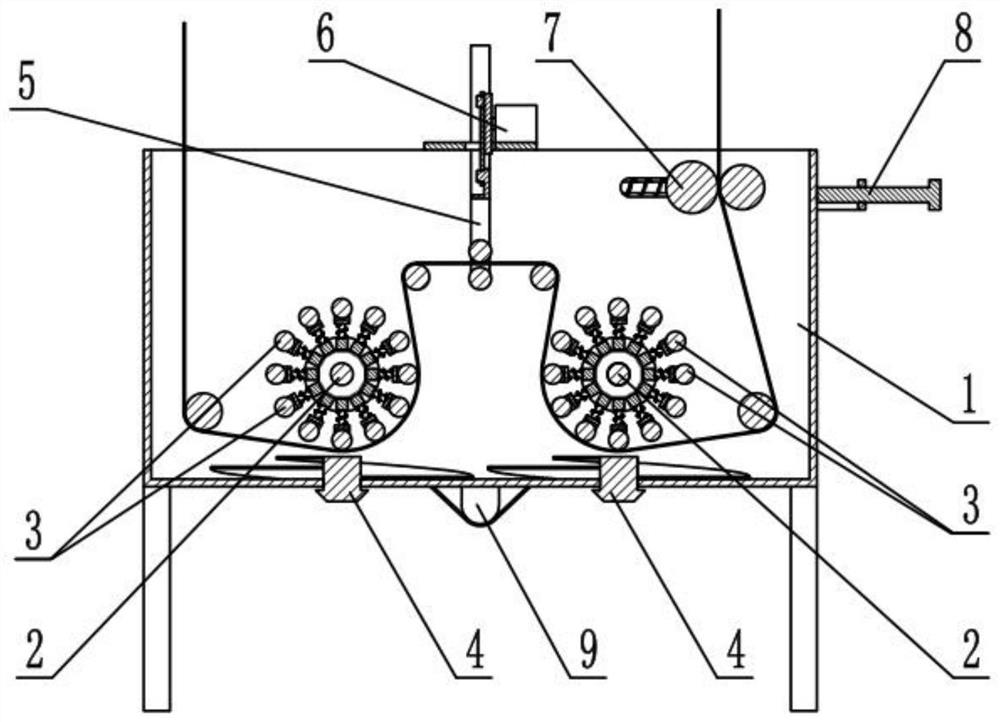

[0034] Such as Figure 1-10 As shown, a clothing antibacterial cloth preparation system includes a soaking box frame 1, a rotating mechanism 2, a cloth beating mechanism 3, a liquid stirring mechanism 4, a vibration mechanism 5, a vibration power mechanism 6, a clamping and dehydrating mechanism 7, and a clamping adjustment mechanism. Mechanism 8 and motor 9, described rotating mechanism 2 is provided with two, and two rotating mechanisms 2 are all rotatably connected in the soaking case frame 1, and are all connected with a plurality of cloth hitting mechanism 3 on two rotating mechanisms 2, so The liquid stirring mechanism 4 is provided with two, and the two liquid stirring mechanisms 4 are all rotatably connected to the lower end of the soaking box frame 1, and the two liquid stirring mechanisms 4 are respectively located directly below the two rotating mechanisms 2, and the two liquid stirring mechanisms 4 are respectively connected to the transmission of the two rotating ...

specific Embodiment approach 2

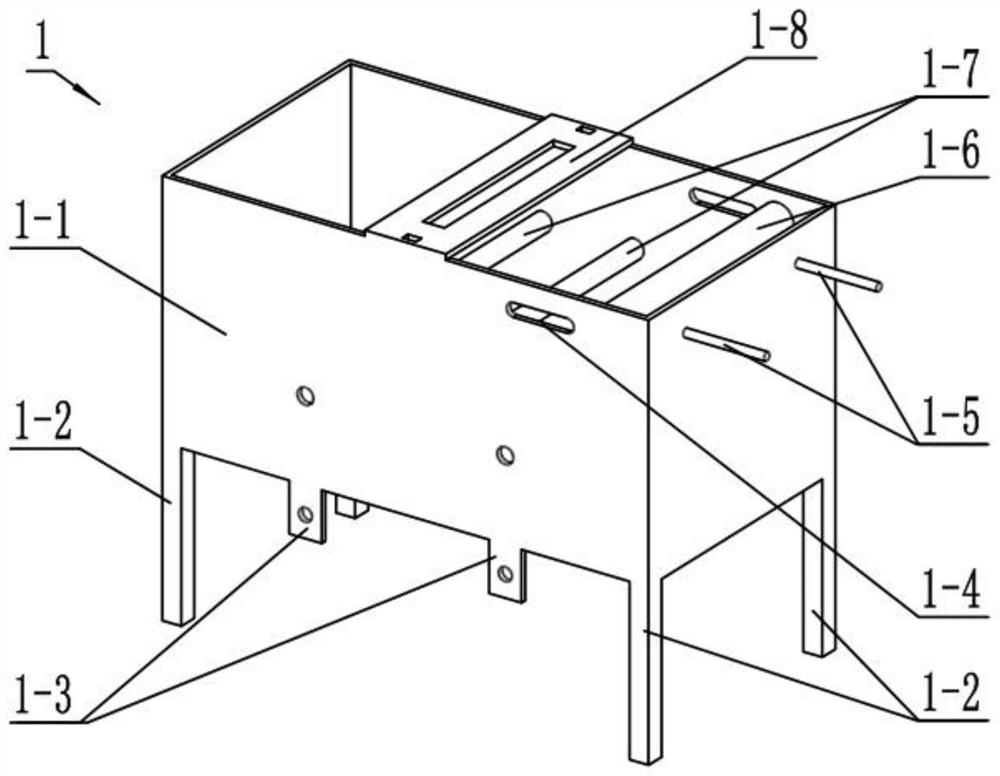

[0037] Such as Figure 1-10 As shown, the soaking box frame 1 includes a box body 1-1, supporting legs 1-2, mounting plate 1-3, sliding slot 1-4, fixed sliding column 1-5, dehydration fixed roller 1-6, Go up block roller 1-7, upper cross plate 1-8 and lower block roller 1-9, the four corners of box body 1-1 lower end are all fixedly connected with supporting leg 1-2, and the lower end of box body 1-1 all There are two mounting plates 1-3 fixedly connected, a long sliding hole 1-4 runs through the box body 1-1, two fixed sliding columns 1-5 are fixedly connected on the right side of the box body 1-1, and the dehydration fixed roller 1-6 is rotatably connected in the box body 1-1 and is located on the right side of the sliding long hole 1-4. There are two upper blocking rollers 1-7, and the two upper blocking rollers 1-7 are rotatably connected to the box body In the middle of 1-1, there are two lower blocking rollers 1-9, the two lower blocking rollers 1-9 are rotatably connec...

specific Embodiment approach 3

[0040] Such as Figure 1-10 As shown, the rotating mechanism 2 includes a rotating shaft 2-1, a rotating side plate 2-2 and a linkage cross bar 2-3, and both ends of the rotating shaft 2-1 are fixedly connected with a rotating side plate 2-2, A plurality of interlocking horizontal bars 2-3 are evenly and fixedly connected in the circumferential direction between the two rotating side plates 2-2, and there are two rotating mechanisms 2, and the two rotating shafts 2-1 are connected to the box Inside the body 1-1, the motor 9 is fixedly connected to the lower end of the box body 1-1, the two rotating shafts 2-1 are located between the two lower blocking rollers 1-9, and the two upper blocking rollers 1-7 are located Between the two rotating shafts 2-1, the motor 9 is connected to the two rotating shafts 2-1 simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com