Metal plate structure combustor of gas stove

A technology of gas stoves and burners, which is applied in the direction of gas fuel burners, burners, and combustion methods, which can solve the problems of high price, lack of availability, and price reduction of dry-burning gas stoves, and achieve the improvement of corrosion resistance and improvement Appearance, the effect of preventing dirt from entering the inner cavity of the cooker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

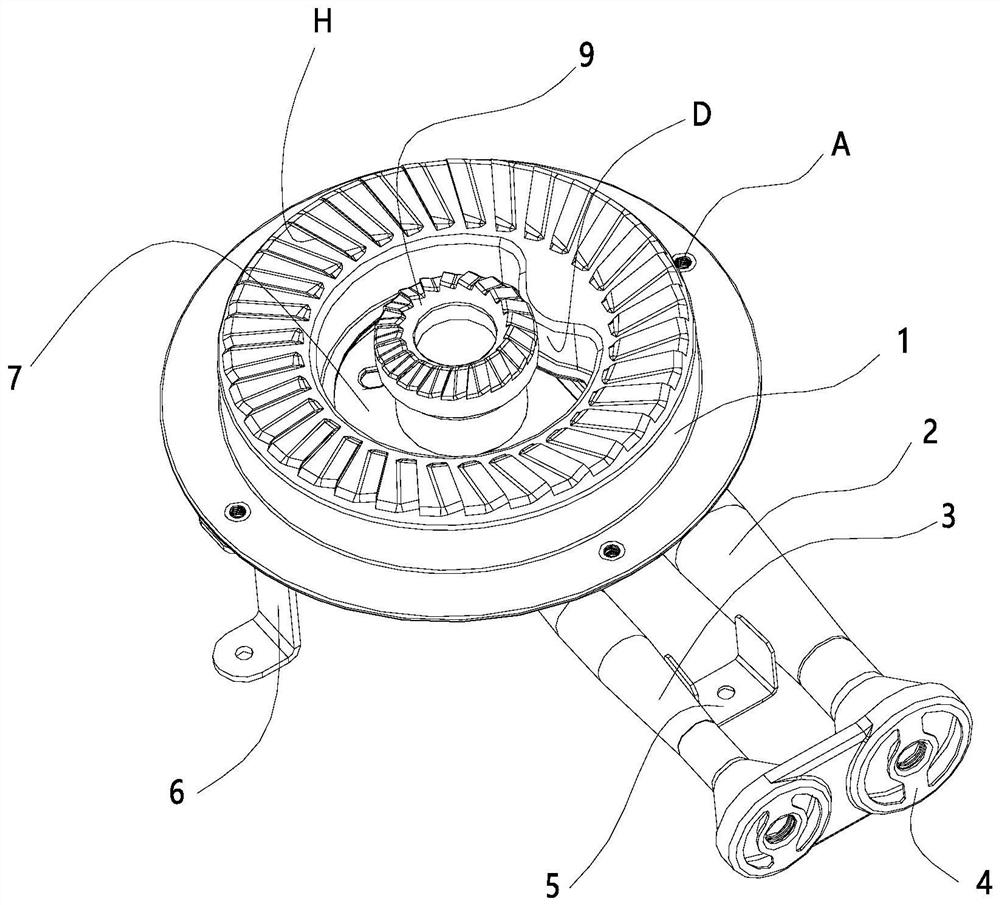

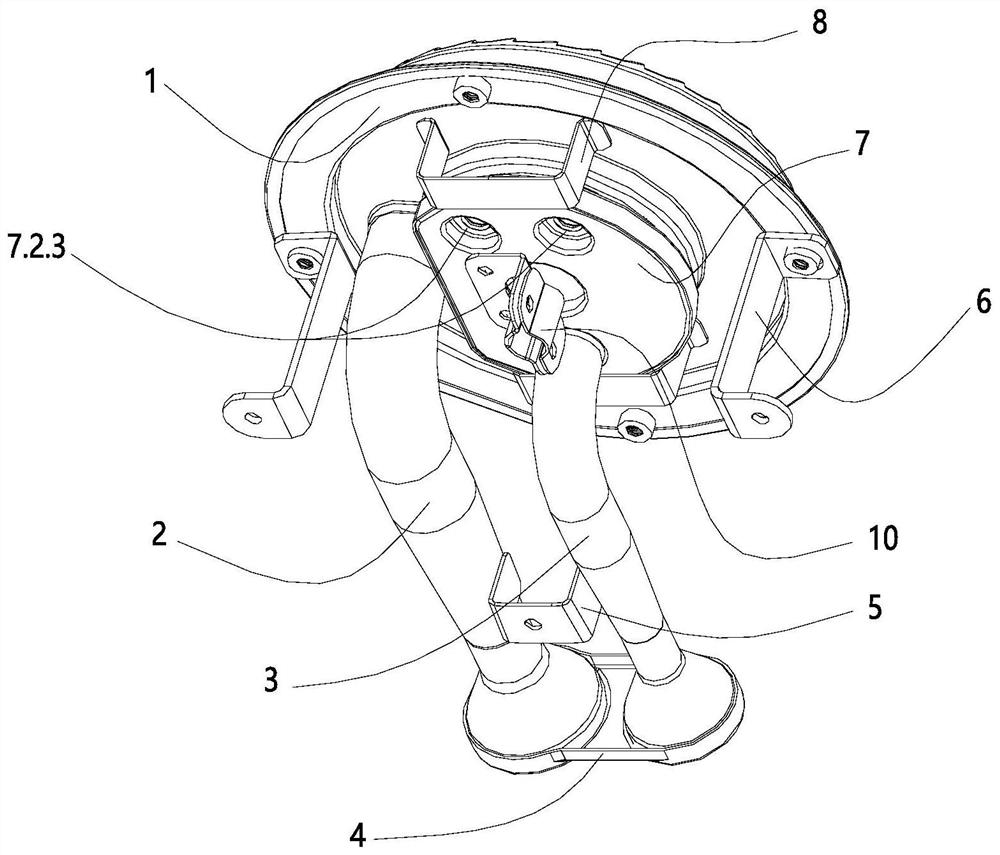

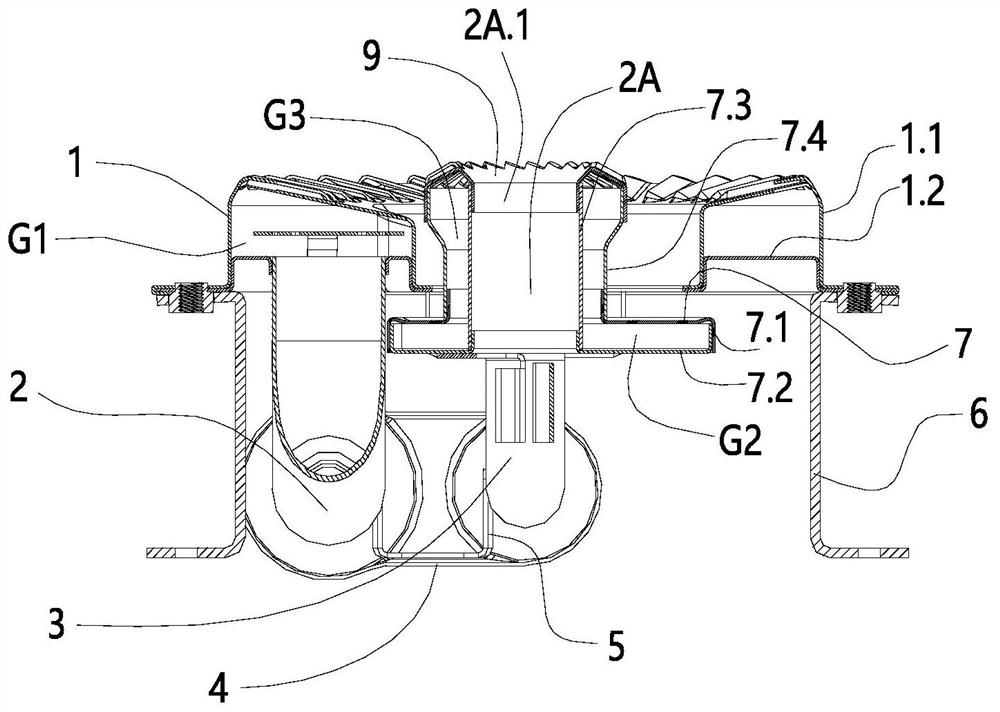

[0044] Such as Figure 1-7 As shown, the sheet metal structure burner of the gas stove in this embodiment, the outer ring fire cover and the burner head are integrated, and the center fire cover has a secondary air channel. The specific implementation is as follows:

[0045]A burner with a sheet metal structure for a gas stove at least includes a burner head, an outer ring fire cover and a central fire cover. , The front mounting bracket 5 and the rear mounting bracket 6 are formed, and the outer ring fire cover is integrated with the burner main body. The burner main body is located at the top of the burner and is disc-shaped, consisting of a main body upper part 1.1 and a main body lower part 1.2 , the outer ring fire cover is integrated with the upper part of the main body; between the upper part of the main body and the lower part of the main body, there is an annular gas mixing chamber G1, the top of the annular gas mixing chamber is conical, and the main body at the bott...

Embodiment 2

[0049] Such as Figure 8 As shown, the specific implementation method of this embodiment differs from that of Embodiment 1 only in that the outer sleeve on the mounting plate of the central injection tube has the same diameter at the upper and lower ends, and the central fire cover with the secondary air channel is an assembly Structure, is made of single fire cover 9 and fire cover seat 9B.

Embodiment 3

[0051] Such as Figure 9 As shown, the specific implementation of this embodiment differs from that of Embodiment 1 only in that this embodiment does not install an anti-dry probe, and a decorative cover 11 is provided at the outlet of the secondary air channel of the central fire cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com