Solid oxide fuel cell and preparation method thereof

A solid oxide and fuel cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of low sealing difficulty, high current collection difficulty, small current collection area, etc., and achieve low sealing difficulty, long durability, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] And a method for preparing a simplified solid oxide fuel cell with reduced cost and time consumption is provided, comprising the following steps:

[0037] Coating powder slurry on one side of the anode flat tube support body containing the air channel to form the anode current collecting structure layer;

[0038] Coating electrolyte slurry on the opposite side of the anode flat tube support body containing air passages to form an electrolyte layer, and sintering at high temperature;

[0039] The cathode is coated on the electrolyte layer of the sintered anode flat tube support body, and sintered at high temperature to obtain a flat tube single-cathode battery with an anode current collecting structure.

[0040] It is mostly carried out by coating and sintering, and the process is simple.

[0041] For the anode flat tube support with air channels, its material can be Ni, NiO or other Ni alloys, or mixed with GDC and YSZ, where GDC: gadolinia-doped cerium oxide, YSZ: ytt...

Embodiment 1

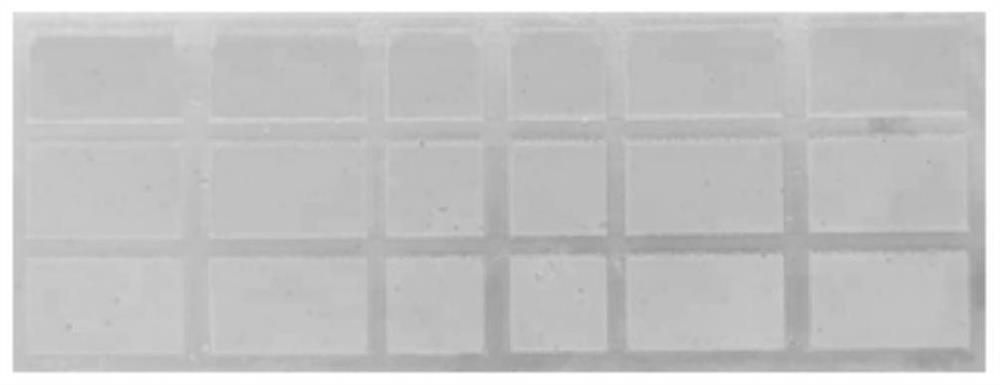

[0052] 1. Using NiO-YSZ composite powder as raw material, the flat tube body is obtained by extrusion molding;

[0053] 2. After calcining the green body at 1000°C to remove the glue, obtain the anode flat tube support body;

[0054] 3. Coating NiO slurry on the A side of the anode flat tube support by screen printing, with a thickness of 15 μm;

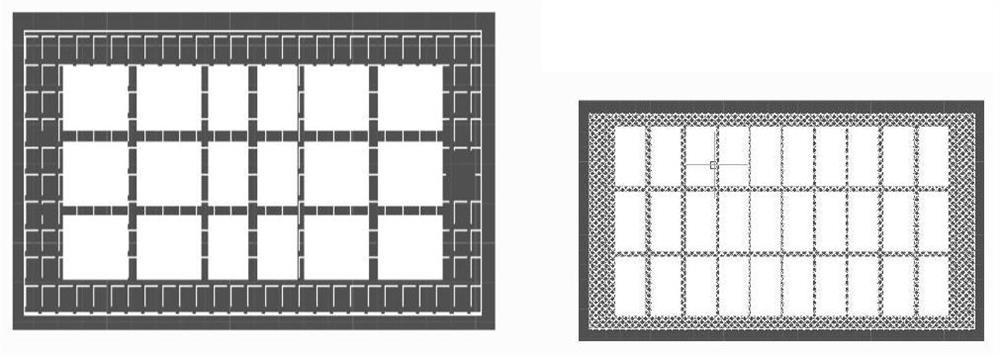

[0055] 4. After air drying, apply YSZ electrolyte slurry grid, the thickness is 8 μm, the grid size is 8*4mm and 4*4mm, and the 4*4mm grid is in the center;

[0056] 5. Dry the anode current collecting structure in step 4, and print the NiO-YSZ active anode slurry on the B side of the flat tube support, with a thickness of 20 μm;

[0057] 6. After drying at 60°C, print YSZ electrolyte slurry on the active anode layer on the B side, with a thickness of 6 μm;

[0058] 7. Sinter at 1300°C for 4 hours to obtain a YSZ half-cell;

[0059] 8. Coat the GDC barrier layer on the B side of the YSZ half-cell with a thickness of 2 μm, and sint...

Embodiment 2

[0062] 1. Using NiO-YSZ composite powder as raw material, the flat tube body is obtained by isostatic pressing;

[0063] 2. After calcining the green body at 800°C to remove the glue, obtain the anode flat tube support body;

[0064] 3. Coating NiO slurry containing 20wt% YSZ on the A side of the flat tube support by screen printing, with a thickness of 12 μm;

[0065] 4. Dry the anode current collecting structure in step 3, and print the NiO-YSZ active anode slurry on the B side of the flat tube support, with a thickness of 15 μm;

[0066] 5. After drying at 60°C, print YSZ electrolyte slurry on the active anode layer on the B side, with a thickness of 10 μm;

[0067] 6. Sinter at 1300°C for 4 hours to obtain a YSZ half-cell;

[0068] 7. Coat the GDC barrier layer on the B side of the YSZ half-cell with a thickness of 1.5 μm and sinter at 1300°C for 4 hours to obtain a GDC half-cell

[0069] 8. Coat the cathode on the B side of the GDC half-cell, with a thickness of 25 μm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com