Process for producing alcohols with clostridium on a solid support

A solid carrier, a technology of the genus Clostridium, applied in a method of sterilization, a method of supporting/immobilizing microorganisms, immobilizing on/in an organic carrier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Example 1 according to the specification: Tests in batch mode with polyurethane foam

[0101] The method of batch mode was carried out experimentally: two fermentations and a control fermentation (cells in suspension) with a solid support of polyurethane foam type with different physical and structural characteristics (foam 1, foam 2). Table 1 below lists the main characteristics of the two foams:

[0102] Table 1

[0103] solid carrier foam 1 bubble 2 Aperture(mm) 0.73 1 Bulk density (g / L) 29.8 20.5

[0104] Several bioreactors were charged with 20 mL of fermentation medium which had been placed under anaerobic conditions in order to ensure the absence of oxygen. A solid volume (apparent volume) of 40% relative to the total volume of the bioreactor was introduced into each bioreactor. Initial glucose was set at 90 g / L and an inoculum rate of 10% (liquid volume) was used with cells at maximum growth rate (same inoculum size for all...

Embodiment 2

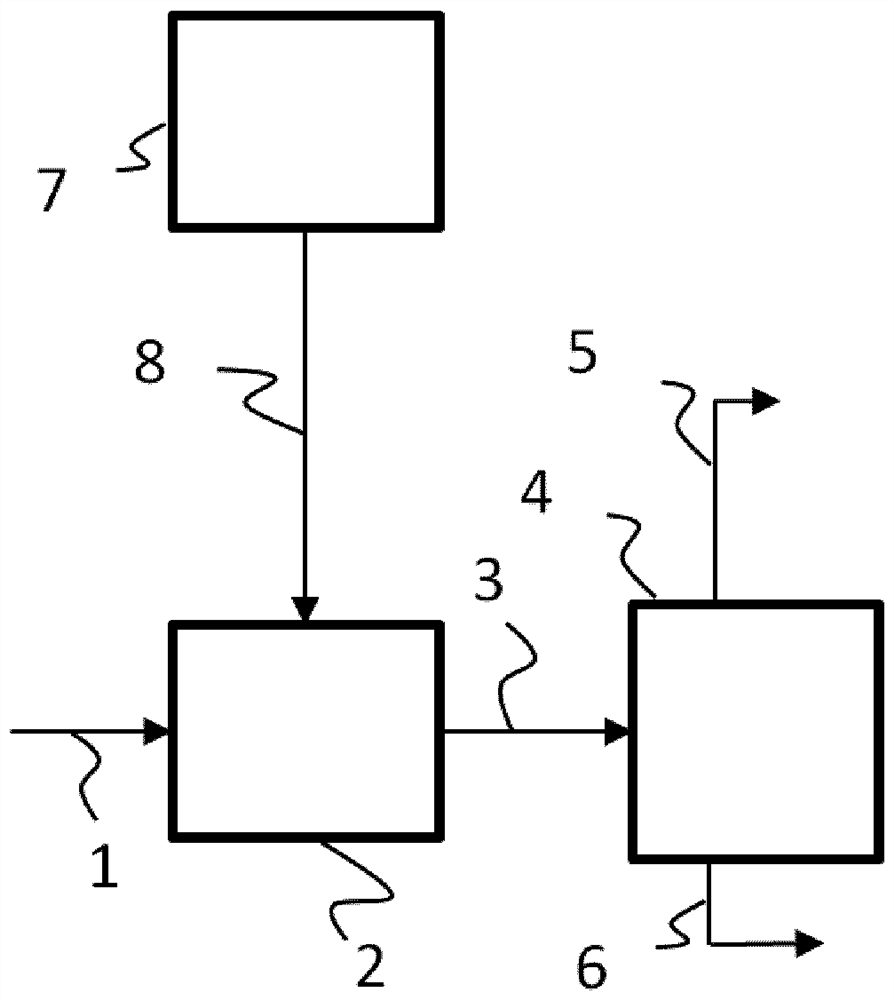

[0109] Example 2 according to the specification: Continuous testing with polyurethane foam

[0110] The method was carried out experimentally according to an embodiment of the present description, using two fermentations in continuous mode and immobilized on a solid support of polyurethane foam type (foam 1, foam 2) with different physical and structural characteristics. The main characteristics of the two foams are listed in Table 1. Filling was performed in a loose pattern with cube dimensions of 3mm x 5mm x 5mm.

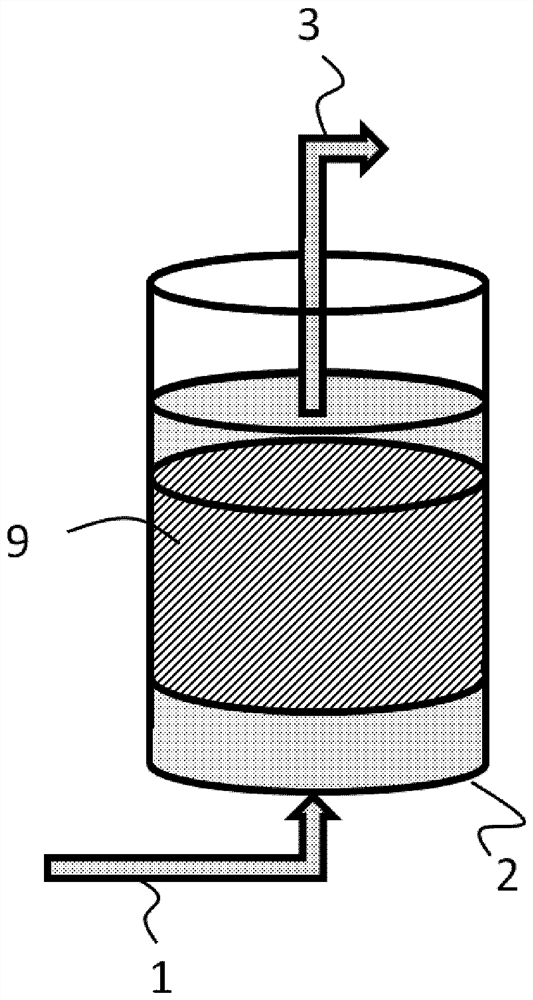

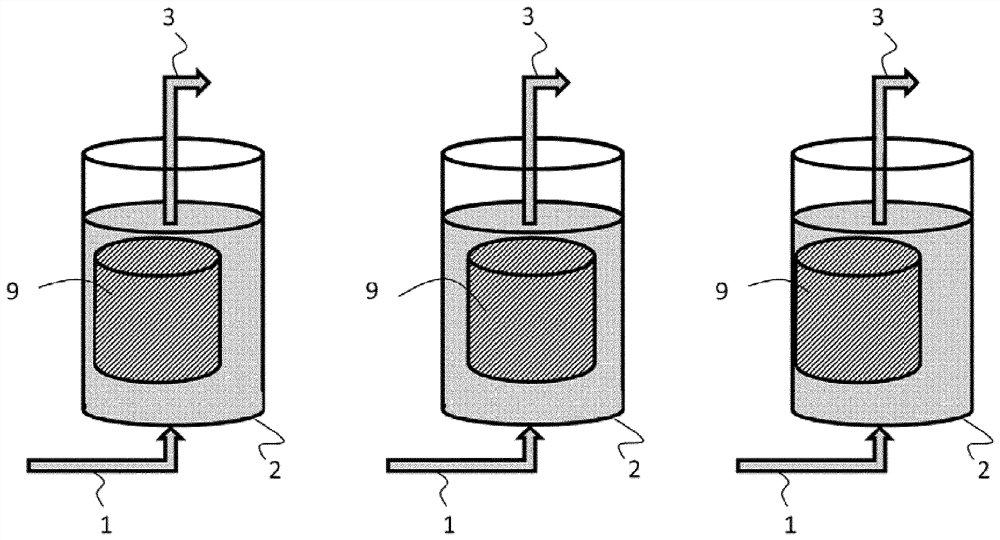

[0111] The solid support was introduced into a 112 ml glass column (dimensions: inner diameter = 32 mm, H = 13.9 cm) whose volume in the column accounted for 50% of the total internal volume of the column. The column was placed in the recirculation loop of the second fermentation bottle, whose volume of fermentation medium was brought to 80 ml. The entire fermentation system was preliminarily placed under anaerobic conditions by purging with nitrogen to ensu...

Embodiment 3

[0120] Example 3 according to the specification: Continuous testing with polyurethane foam

[0121] The method was carried out experimentally according to an embodiment of the present description, using two fermentations in continuous mode and immobilized on a solid support of polyurethane foam type. Filling was performed in a loose pattern with cube dimensions of 10mm x 10mm x 7mm. The foam has a macropore size of about 1 mm.

[0122] Both fermenters were in the form of glass columns with a working volume of 250 ml. The filling conditions of the fermenters are listed in Table 4.

[0123] Table 4

[0124]

[0125] A recirculation loop is provided between the inlet and outlet of the reactor to maintain good homogenization in the fermenter. The liquid outlet is overflowing. The entire fermentation system was preliminarily placed under anaerobic conditions by purging with nitrogen to ensure the absence of oxygen. The glucose concentration in the raw material tank was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Dilution degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com