Magnesium wire feeding desulfurization device and method

The technology of a desulfurization device and magnesium wire is applied in the field of iron and steel smelting, which can solve the problems of reducing the service life of the lance tube, the burning loss of the refractory material layer, and the high production cost, and achieves the advantages of reducing the heating cost, the temperature drop of the molten iron, and the device being simple and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

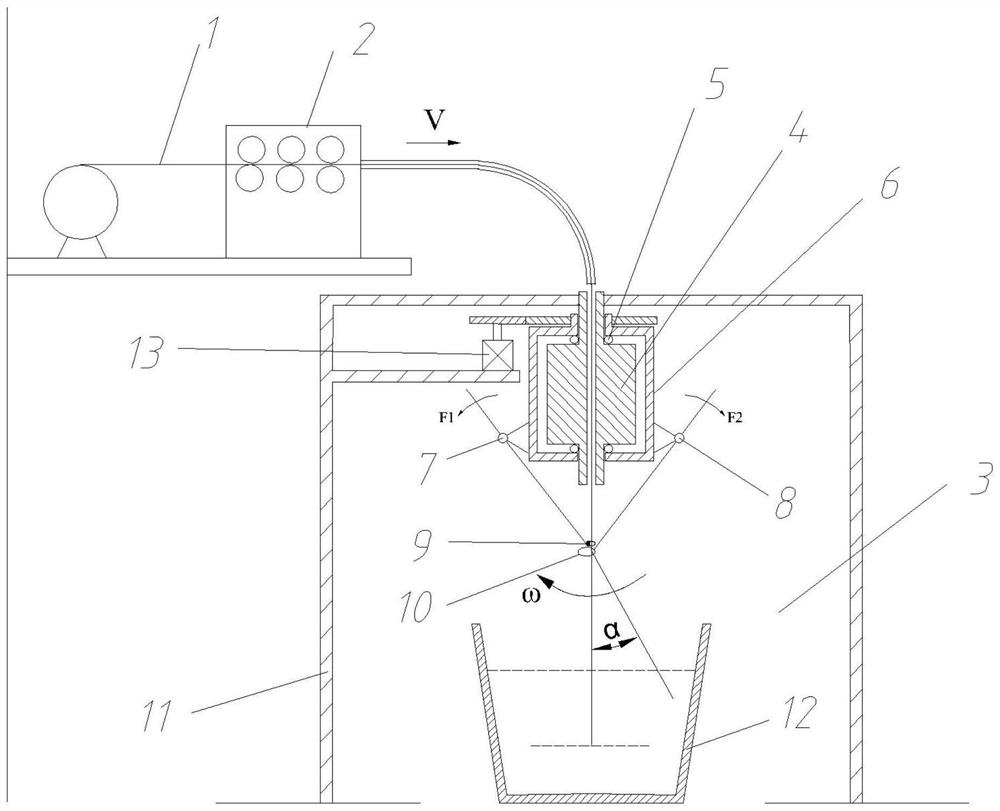

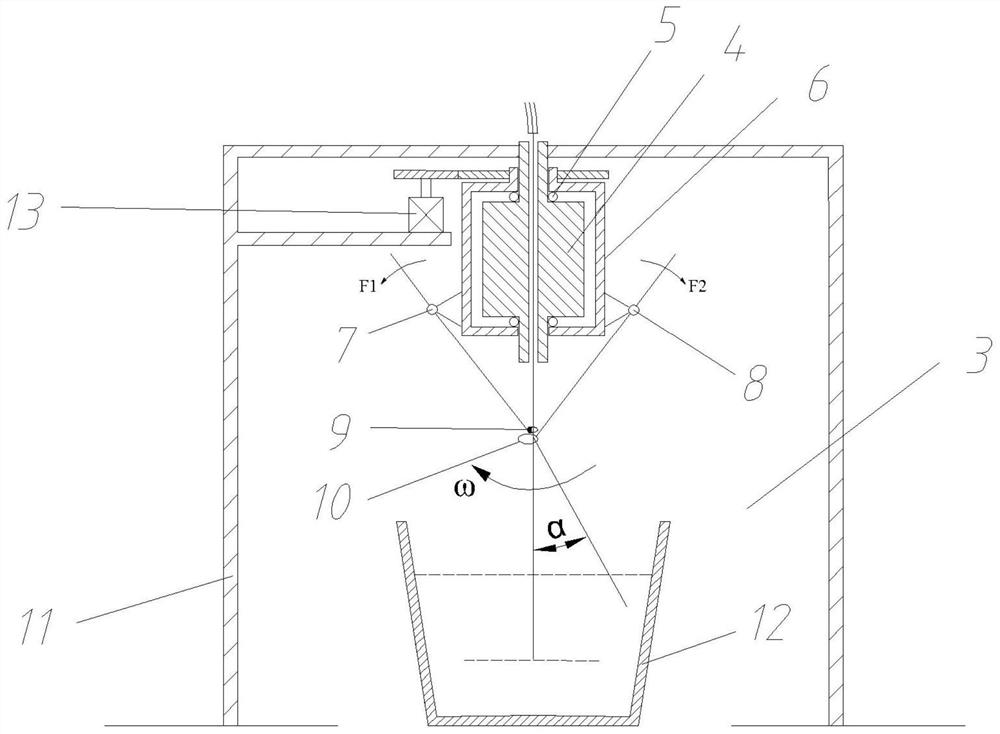

[0017] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation modes in conjunction with the accompanying drawings.

[0018] Such as Figure 1-2 As shown, a magnesium wire desulfurization device includes a wire feeding device and a rotatable agitating device 3, the wire feeding device is a wire feeding machine 2, and the agitating device 3 is arranged between the wire feeding device and the ladle 12, which can Change the direction in which the magnesium wire 1 enters the ladle 12, the outlet of the conduit of the wire feeding device is aligned with the inlet of the agitating device 3, the outlet of the agitating device 3 is aligned with the inlet of the ladle 12, and the magnesium wire 1 passes through the agitating device 3 after passing through the wire feeding device After changing the direction, it enters the ladle 12; the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com