Flat plate capillary pump assembly

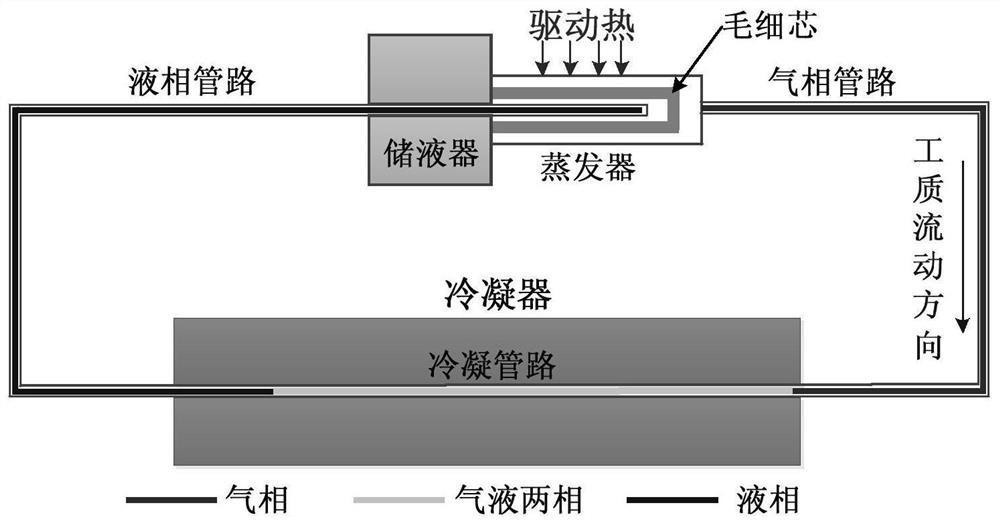

A capillary pump and ceramic core technology, applied in the field of flat capillary pump components, can solve the problems of flat plate loop heat pipe failure, easy deformation of the flat plate structure, discounted heat transfer performance of the evaporator, etc., to achieve good precision machining performance, guarantee Effect of large open porosity and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further elaborated below in conjunction with embodiment.

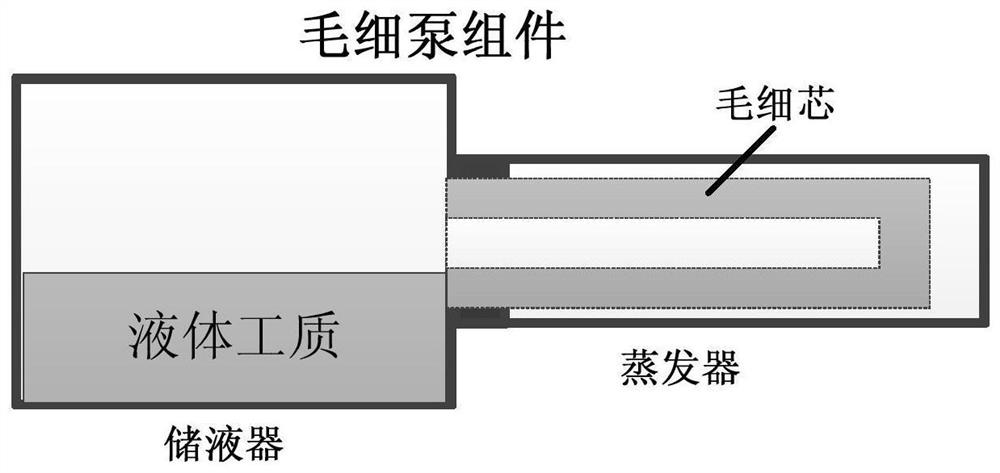

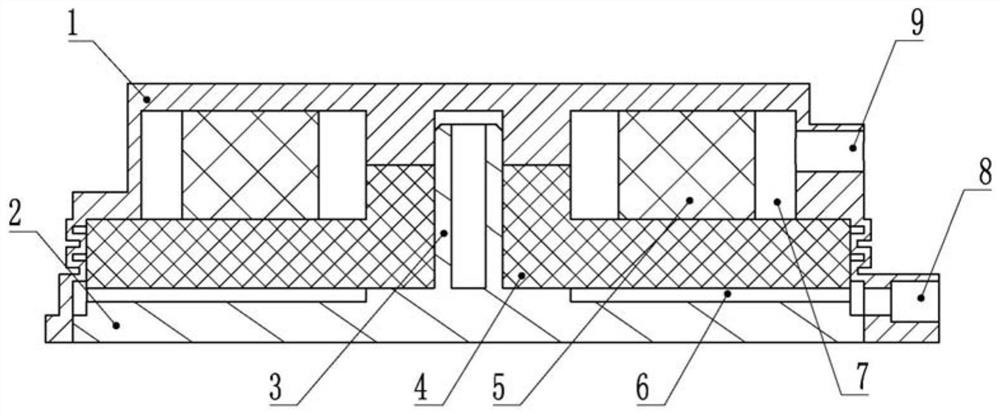

[0048] Such as Figure 3-6 As shown, a flat capillary pump assembly based on a ceramic core includes a liquid reservoir shell, an evaporator bottom plate, a connecting rod, a main core, and a secondary core.

[0049] The shell of the liquid reservoir is a cylindrical cavity structure, the contact part between the side wall and the capillary core is a corrugated structure, and there is a boss on the top of the shell, and there is a threaded opening in the boss; the inner wall of the corrugated structure of the liquid reservoir shell and the main The side wall of the core is in contact, and sealant is filled in the corrugated structure of the inner wall of the liquid storage shell to ensure the sealing of the main core and the side wall of the liquid storage shell; the liquid storage shell and the bottom plate of the evaporator are connected by a connecting rod, and the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com