Method for producing cylindrical sputtering target

A manufacturing method and cylindrical technology, applied in the directions of sputtering plating, vacuum evaporation plating, coating, etc., can solve the problems of poor bonding, time-consuming, difficult to avoid poor bonding, etc., to prevent poor bonding and improve the finished product. Good efficiency and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

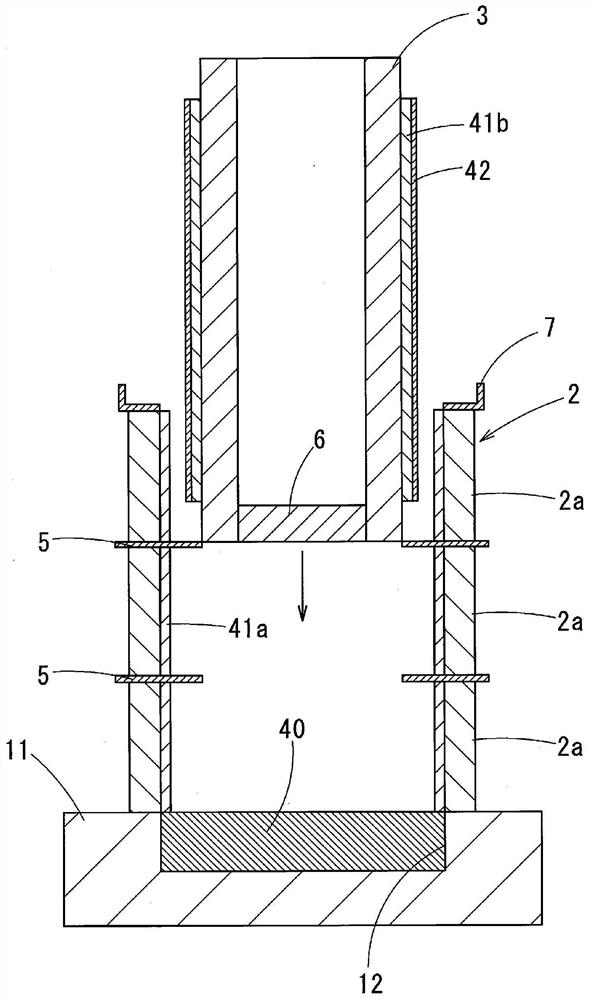

[0086] In order to confirm the effects of the present invention, experiments were conducted. For the target and the liner, materials of the material type shown in Table 1 were used, and a material coated with a surface-treated bonding material and a material not coated with a surface-treated bonding material were prepared. In addition, SIZ, which is the target type in Example 4, means a sintered oxide of Si, In, and Zr, AZO in Example 5 means a sintered oxide of Al and Zn, and CuNi in Example 6 means a sintered oxide of Cu and Ni. As for the alloy, CuCuO in Example 7 refers to a sintered body of Cu and CuO, and CuGa in Examples 8 to 11 and Comparative Example 2 refers to an alloy of Cu and Ga. As described in Table 1, pure indium, tin alloy, and pure tin were used as the substrate treatment bonding material. When performing surface treatment, use warm air to heat until the surface temperature reaches 240°C to 260°C, apply the surface treatment bonding material in the atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com