Latex sponge and vertical sponge combined mold cup and preparation method thereof

A latex and mold cup technology, applied in the field of clothing production, can solve the problems of high cost of mold cups, not resistant to washing, poor support, etc., to achieve the effect of not easily breeding harmful bacteria, not producing toxic substances, and pleasant wearing experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The mold cup that latex cotton is combined with standing cotton

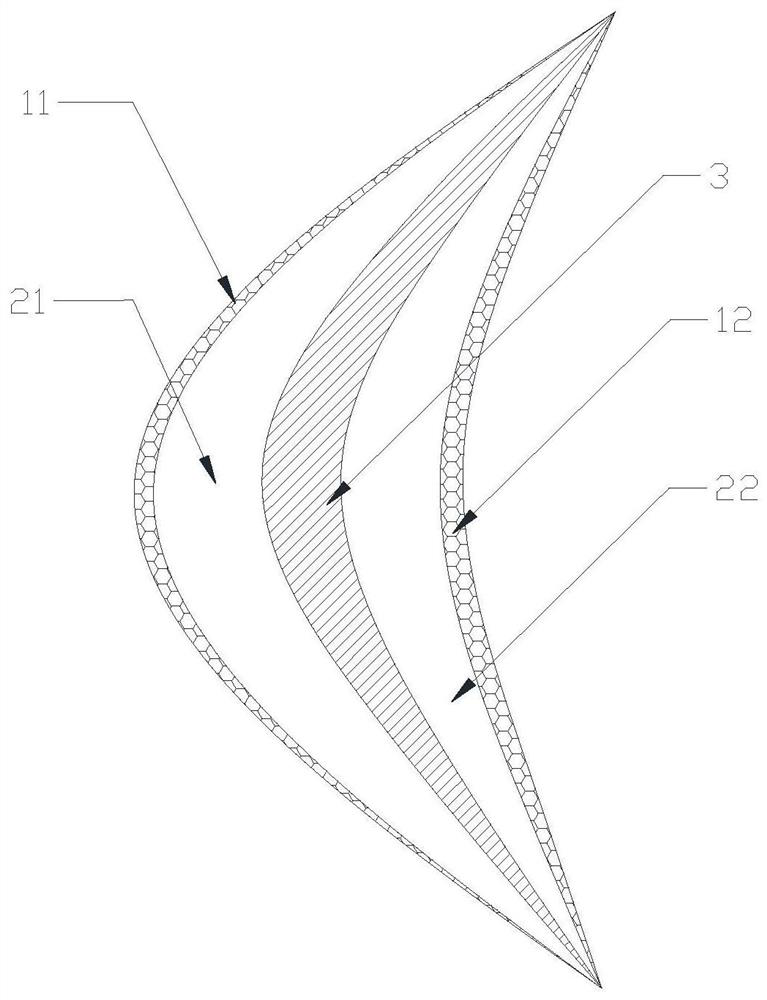

[0034] see Figure 1-3 , the mold cup that the thin section latex cotton in the present embodiment is combined with standing cotton comprises successively the first fabric layer 11, the first cotton layer 21, the second cotton layer 22 and the second fabric layer 12, the first fabric layer 11 and the second fabric layer Between the second cotton layer 22, between the second fabric layer 12 and the second cotton layer 22, there is full fit. In this embodiment, the material of the first cotton layer 21 is cotton, and the material of the second cotton layer 22 is latex cotton.

[0035] The weight of the standing cotton layer is 160-170g / m under the thickness of 10mm 2 ; Latex cotton is 80% natural latex with a certain amount of foaming agent added and then foamed into a sponge body. The chips are sheets with a width of 1.5m, a thickness of 3mm and an unlimited length. The density is 70-80kg / m ...

Embodiment 2

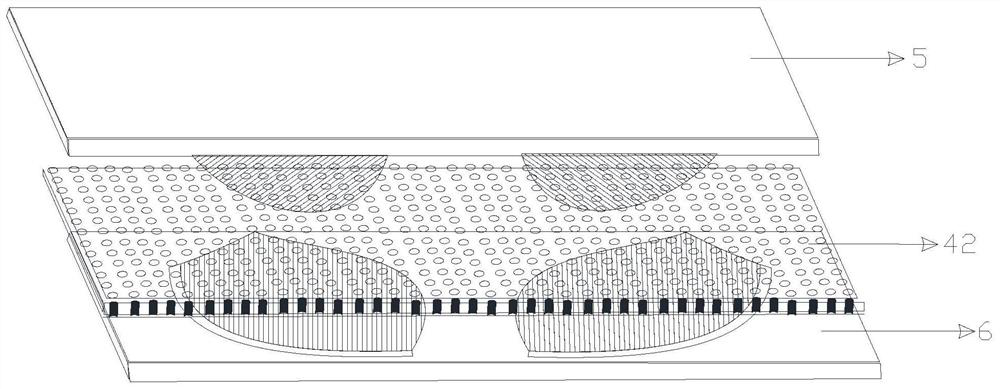

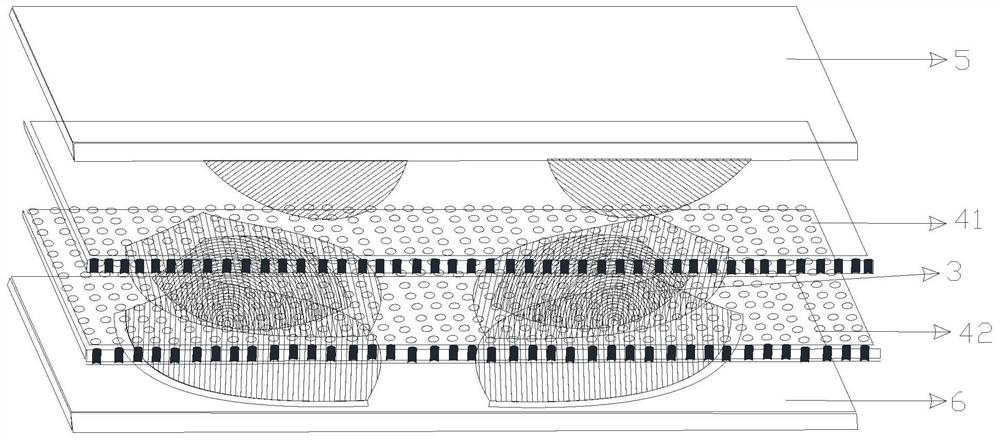

[0064] Embodiment 2 The mold cup that latex cotton is combined with vertical cotton

[0065] see figure 1 and 4 , the latex cotton in the present embodiment and the mold cup that the vertical cotton is combined and its preparation method are basically the same as embodiment 1, the difference is that the first composite material 41 in the present embodiment is formed after the fabric and the latex cotton are pasted together, the second The second composite material 42 is formed after the fabric is bonded to the vertical cotton, and the latex cotton has air holes, but the vertical cotton does not have air holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com