High-precision false tooth and manufacture method thereof

A high-precision denture technology, applied in the field of denture manufacturing, can solve problems such as large errors, difficult control of the quality of fixed denture restorations, and uneven levels of manual production, achieving high density, improving accuracy and quality reliability, and The effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The application will be described in further detail below in conjunction with the accompanying drawings.

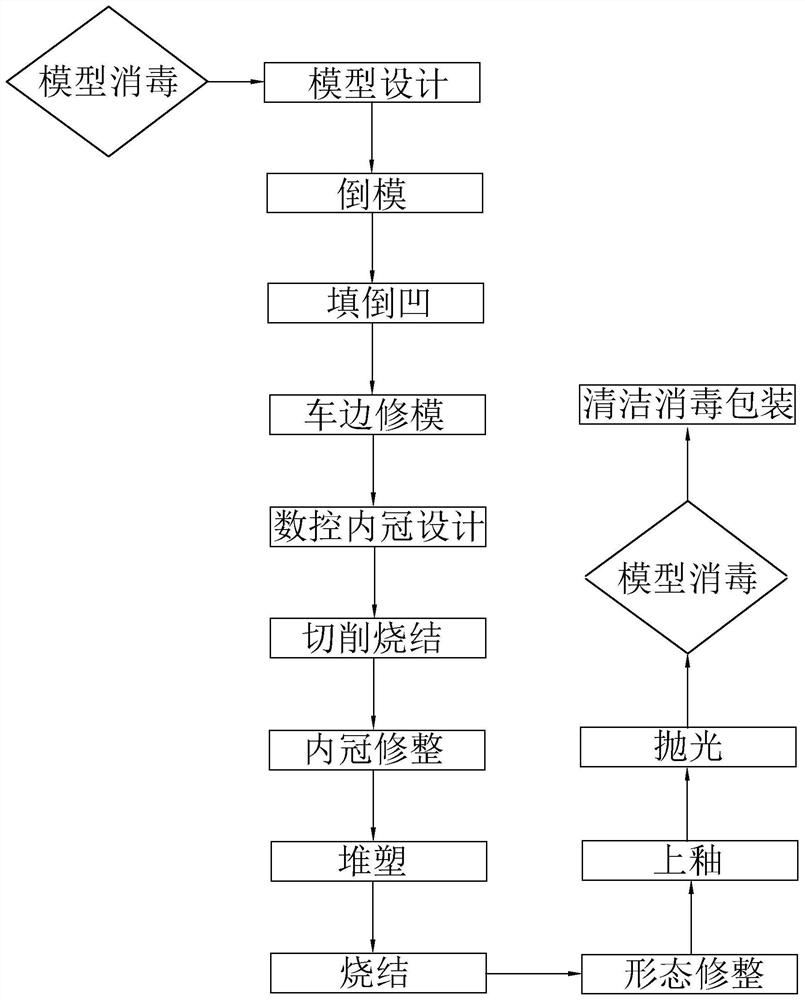

[0049] refer to figure 1 , a method for preparing a high-precision denture disclosed in the embodiment of the present application, comprising the following steps:

[0050] S1. Disinfect the model. After receiving the original dental model from the dentist, carry out a disinfection inspection on the dental model. If the inspection is qualified, go to the next step. If the unqualified product is submitted to the dentist for re-modeling, the model is filled with plaster from the tooth marks left by the patient's oral cavity. For the generated dental model, two kinds of disinfection methods are selected: ultraviolet irradiation method and model disinfection and sterilization machine, so as to reduce blood, saliva and bacteria on the dental model and have a small impact on the dental model.

[0051] S2. Model design. Use a model trimmer to trim the bottom and surroundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com