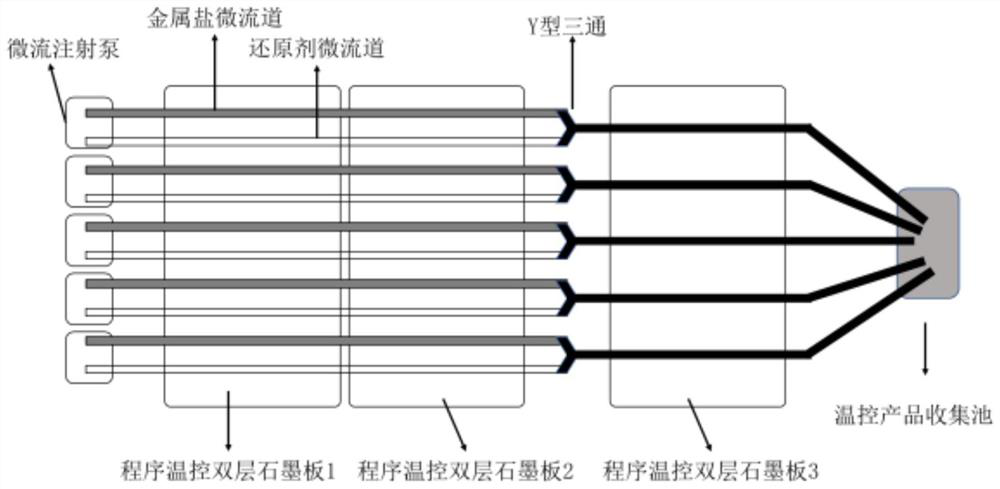

Device and method for large-scale continuous preparation of metal nanoparticles

A technology of metal nanoparticles and micro-channels, applied in the direction of nanotechnology, can solve the problems of unstable product quality, high catalyst cost, low output, etc., and achieve low solvent flow resistance, strong platform applicability, and straight structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

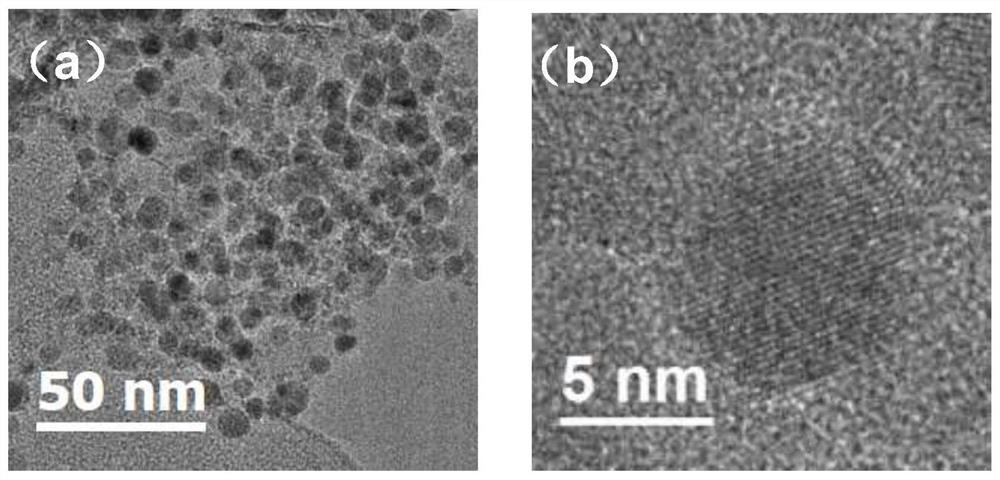

[0026] Preparation of FeAg nanoparticles: metal salt solution (iron nitrate, silver nitrate) is set to be 3mmol / 50mL, reducing agent solution (sodium borohydride) is 12mmol / 50mL, solvent is dimethylpyrrolidone, and surfactant is polyethylene Pyrrolidone; the temperature of program temperature-controlled double-layer graphite plate 1 is 100°C, the temperature of program temperature-controlled double-layer graphite plate 2 is 100°C, and the temperature of program temperature-controlled double-layer graphite plate 3 is 100°C; the temperature of collected products is 0°C; injection pump The flow rate was 1 mL / min.

Embodiment 2

[0028] Preparation of FeAg nanoparticles: metal salt solution (iron nitrate, silver nitrate) is set to be 3mmol / 50mL, reducing agent solution (sodium borohydride) is 12mmol / 50mL, solvent is dimethylpyrrolidone, and surfactant is polyethylene Pyrrolidone; the temperature of program temperature-controlled double-layer graphite plate 1 is 120°C, the temperature of program temperature-controlled double-layer graphite plate 2 is 120°C, and the temperature of program temperature-controlled double-layer graphite plate 3 is 120°C; the temperature of collected products is 0°C; injection pump The flow rate was 1 mL / min.

Embodiment 3

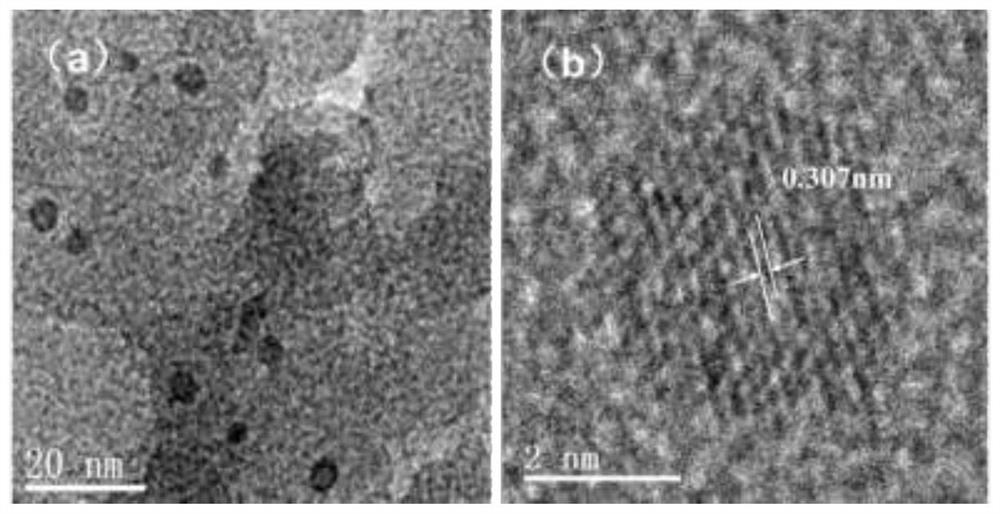

[0030] Preparation of FeAg nanoparticles: metal salt solution (iron nitrate, silver nitrate) is set to be 3mmol / 50mL, reducing agent solution (sodium borohydride) is 12mmol / 50mL, solvent is dimethylpyrrolidone, and surfactant is polyethylene Pyrrolidone; the temperature of program temperature-controlled double-layer graphite plate 1 is 140°C, the temperature of program temperature-controlled double-layer graphite plate 2 is 140°C, and the temperature of program temperature-controlled double-layer graphite plate 3 is 140°C; the temperature of collected products is 0°C; injection pump The flow rate was 1 mL / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com