Semi-conical wave-transparent radome machining device and method

A technology for processing devices and radomes, which is applied to manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of inability to meet precision requirements, affect processing precision, and high processing precision requirements, so as to improve processing efficiency and processing accuracy, and achieve high High precision machining and high position accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

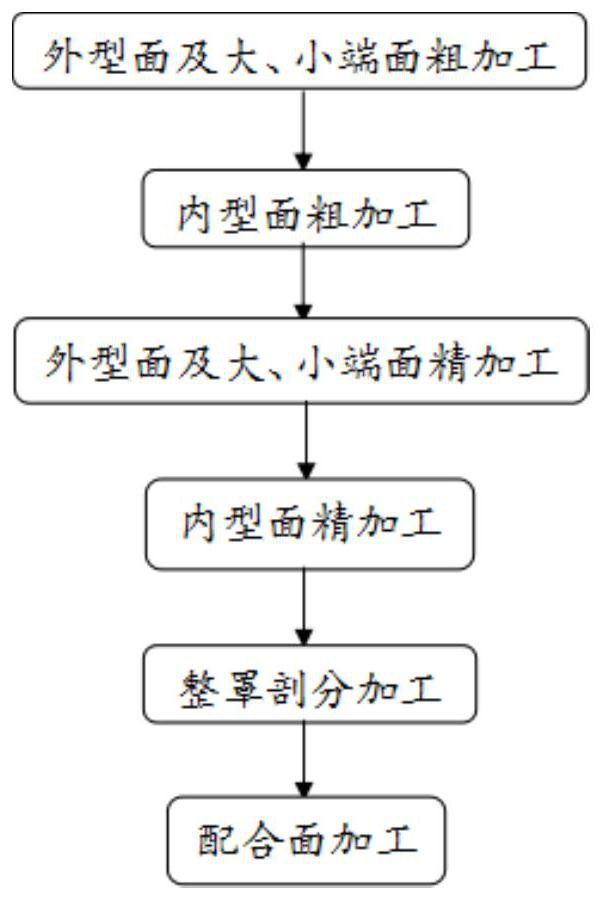

[0075] Machining object Figure 5 The ceramic matrix composite material is complex structure heeled transmitted antenna cover blank, and its processing flow is figure 1 As shown, including the following steps:

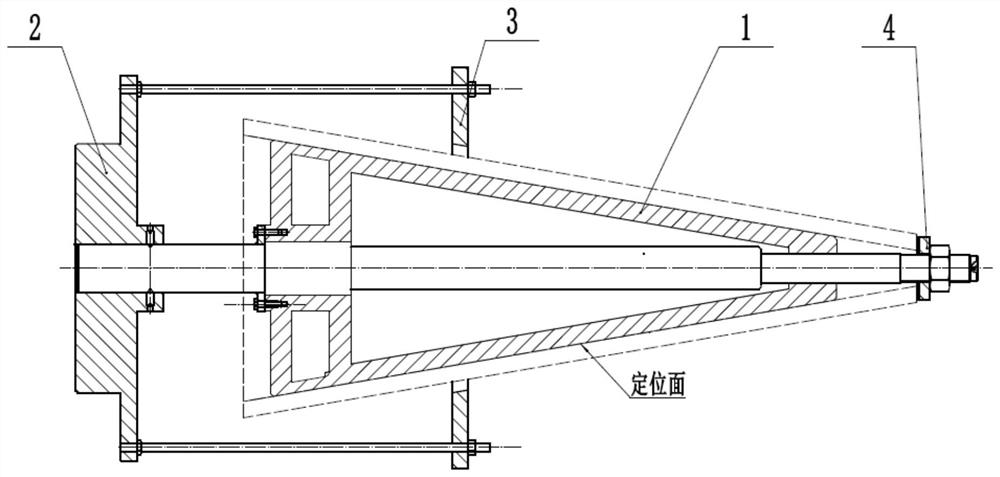

[0076] (1) Rough processing of the outer shape, large end face, small end face: Using the outer cranked car cutting tool, such as figure 2 For the outer surface of the workpiece and large end, the small end face is rough. Big, small-end round jump is not more than 0.1mm, and the length of the workpiece is not less than 5 mm after workpiece processing, and the outer surface thickness direction is not less than 1 mm, and the outer cone is vertical and large end surface verticality. No more than 0.1mm.

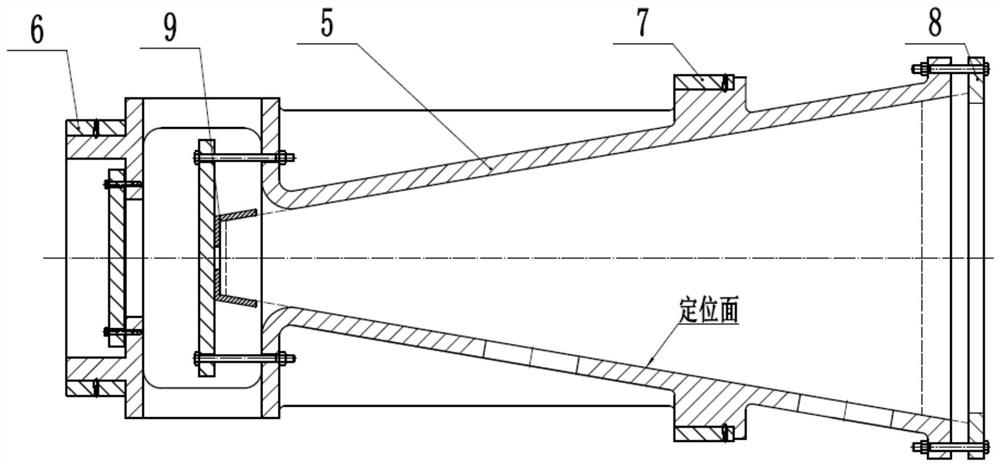

[0077] (2) Endotype face rough processing: Utilizing the inner cranked machine, such as image 3 As shown, the workpiece is in-mold. The inner cavity round jump of the constrained in-line machining device is no more than 0.1 mm, and the end surface of the workpiece is not more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com