Ceramic bathroom ware slip casting process and intelligent equipment

A technology of grouting molding and intelligent equipment, which is applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve problems such as unevenness, cracking and damage of adobe, thin and thick inner walls, and adobe quality that does not meet the requirements, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment discloses a ceramic sanitary ware grouting molding process, which specifically includes the following steps:

[0038] Mold fixing: clean the mold and then close the mold, and fix the mold after clamping to ensure the sealing of the mold after clamping;

[0039] Mold grouting: Place the clamped and fixed mold on the turntable to keep rotating at a low speed, and then slowly pour the prepared slurry into the mold;

[0040] Mold pouring: place the mold after grouting in a cool and ventilated place until the grout on the inner wall of the mold solidifies, and pump out the excess grout;

[0041] Mold inversion: After the mold pouring is completed, invert the mold and make the mold vertically inverted to ensure that the excess slurry inside is controlled, and placed in a ventilated and dry place until the slurry on the inner wall of the mold is completely cured and dried;

[0042] Take the bisque: After the slurry on the inner wall of the mold is completely c...

Embodiment 2

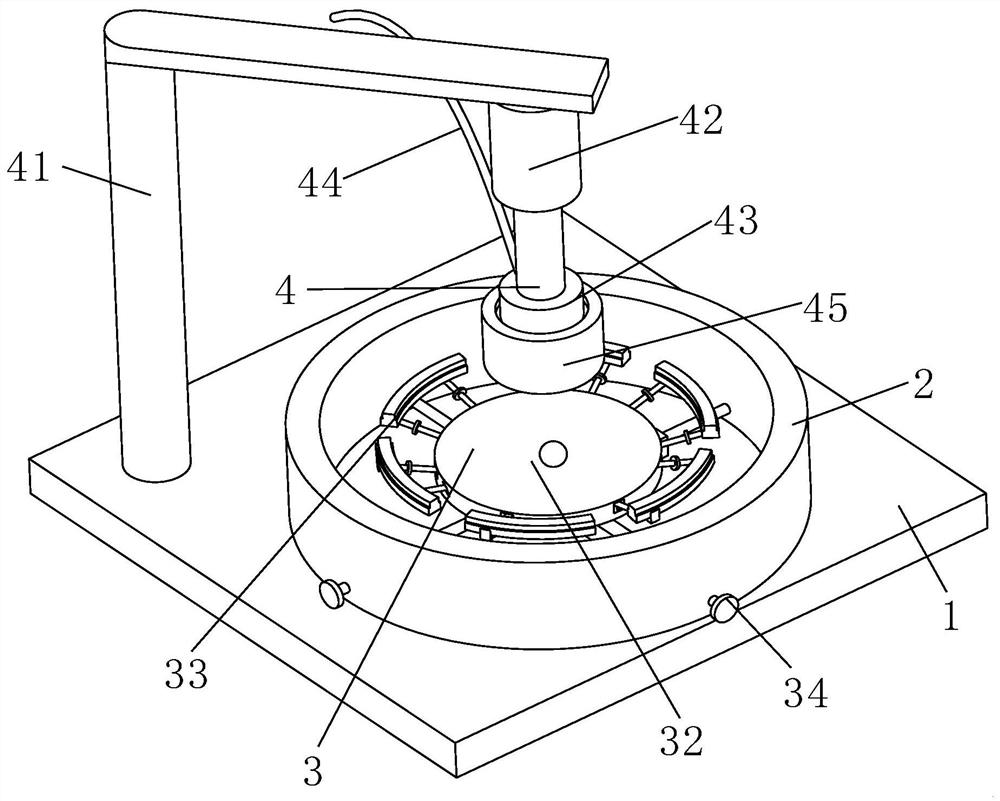

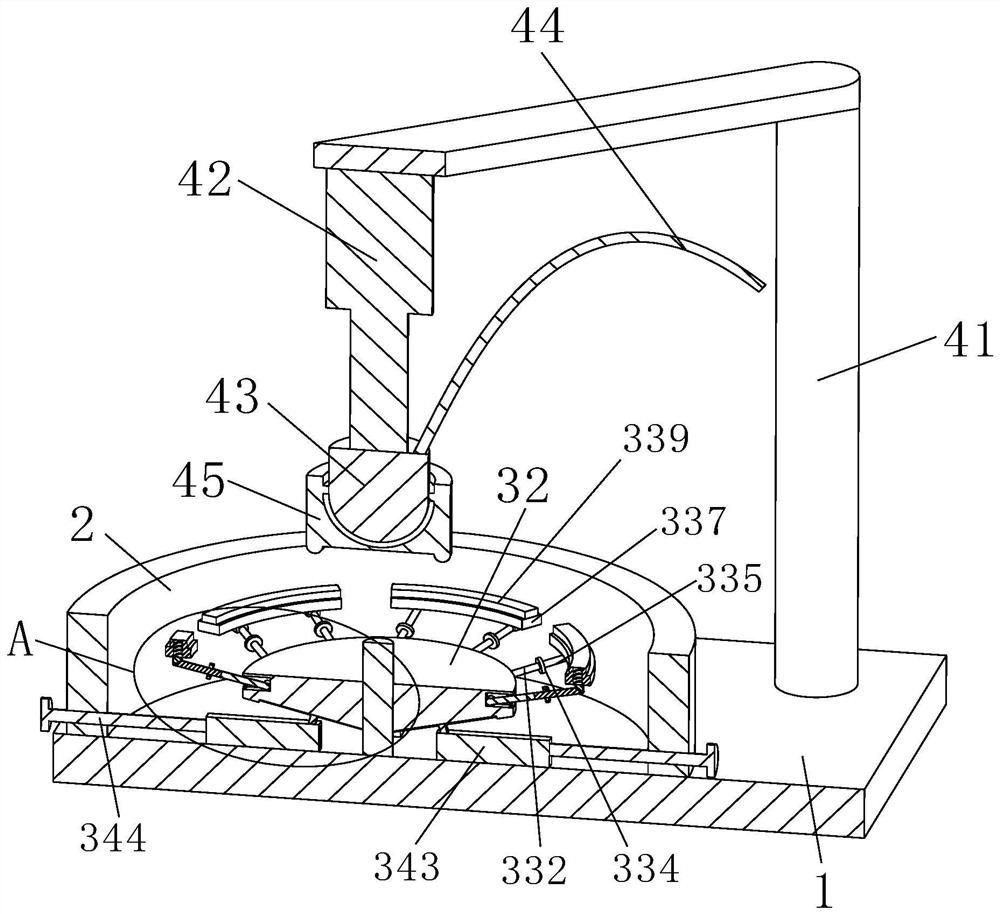

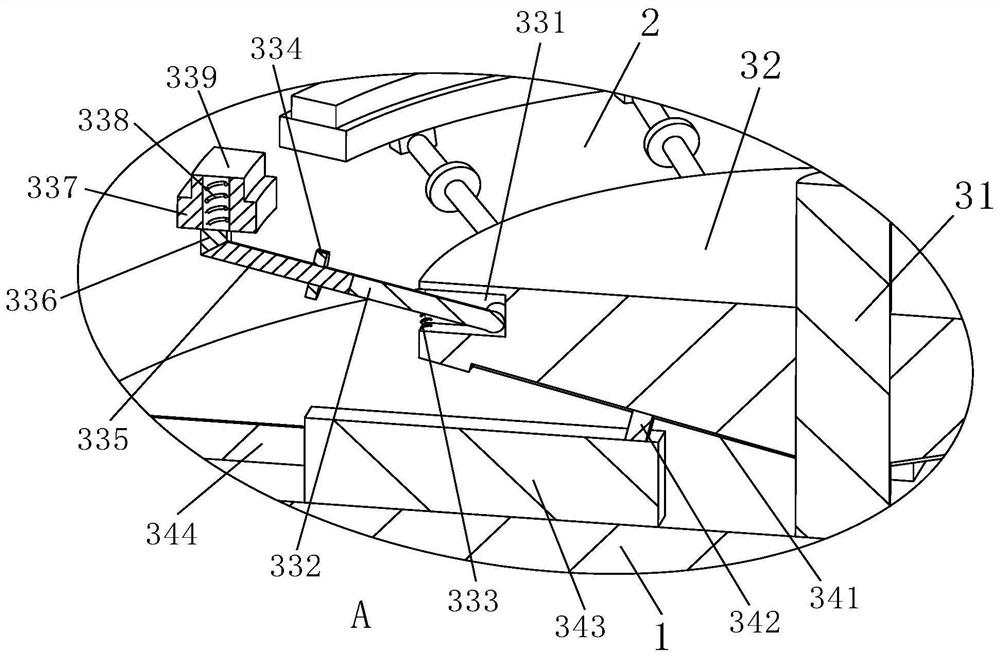

[0046] see Figure 1-4 , this embodiment also provides an intelligent device for ceramic sanitary ware grouting molding, which is applied to the molding process of the above embodiment, including a placement board 1, a placement table 2 is arranged on the placement board 1, and a protective component 3 is arranged in the placement table 2 , The upper end of the placing plate 1 is also provided with a slurry suction assembly 4 for extracting the slurry in the mould.

[0047] refer to figure 2 and Figure 4 , suck out excess slurry in the mould: the slurry suction assembly 4 includes an L-shaped rotating arm 41 arranged on the upper end surface of the placing plate 1, the lower end of the rotating arm 41 is provided with an electric push rod 42 compatible with the placing table 2, and the electric push rod 42 The top is provided with a suction pump 43, the upper end of the suction pump 43 is provided with a water outlet pipe 44, and the liquid inlet at the lower end of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com