Starch foaming material and preparation method thereof

A foaming material and starch technology, applied in the field of starch foaming material and its preparation, can solve problems such as uneven foaming, decrease in mechanical properties and cushioning properties of starch foaming material, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

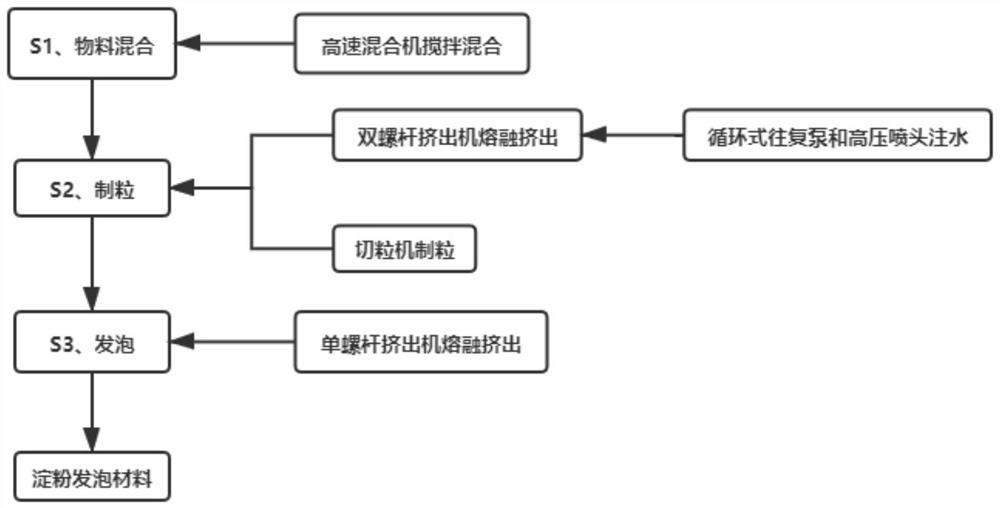

[0033] Based on the above inventive concept, the present invention also provides a preparation method of starch foaming material, please refer to figure 1 , including the following steps:

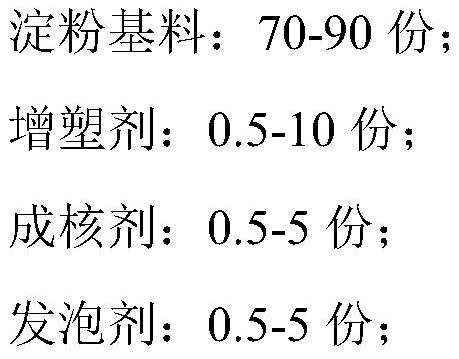

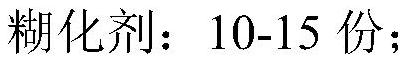

[0034] S1. Material mixing: Prepare raw materials according to the above composition of starch foaming material, weigh 70-90 parts of starch base material, and add 0.5-10 parts of plasticizer, 0.5-5 parts of nucleating agent, and 0.5 parts of foaming agent in sequence. -5 parts, 10-15 parts of gelatinizer, stir in a high-speed mixer at a speed of 500-1000rmp and a temperature of 60-80°C for 5-10min to obtain a mixed material;

[0035]S2. Granulation: Melt and extrude the mixed material in step S1 with a twin-screw extruder, and pelletize it with a pelletizer to obtain thermoplastic starch pellets; wherein, the twin-screw extruder is equipped with multi-stage shear mixing Heating intervals; there are seven multi-shear mixing heating intervals, which are the first heating interval, whose tem...

Embodiment 1

[0042] Embodiment 1 of the present invention provides a kind of starch foaming material, comprises the following components in parts by weight:

[0043]

[0044] Wherein, the whipping agent is sodium carbonate; the pasting agent is water. The starch base material is wheat starch. Described plasticizer is polyethylene glycol. The nucleating agent is calcium carbonate.

[0045] The preparation method of embodiment 1 of the present invention is, comprises the following steps:

[0046] S1. Material mixing: Prepare raw materials according to the composition of the above-mentioned starch foaming material, weigh 75 parts of starch base material, and add 7 parts of plasticizer, 3 parts of nucleating agent, 4 parts of foaming agent, and 10 parts of gelatinizer in sequence. In a high-speed mixer, stir at a speed of 700rmp and a temperature of 70°C for 10 minutes to obtain a mixed material;

[0047] S2, granulation: extrude the mixed material in step S1 with a twin-screw extruder,...

Embodiment 2

[0050] Present embodiment 2 provides a kind of starch foaming material, by weight, comprises the following components:

[0051]

[0052] Wherein, the whipping agent is sodium carbonate; the pasting agent is water. The starch base material is a combination of tapioca starch and wheat starch. Described plasticizer is polyethylene glycol. The nucleating agent is calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com