Heat-conducting composite material as well as preparation method and application thereof

A technology of thermally conductive composite materials and polymers, which is applied in heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc. The effect of controlling the direction of heat transfer and the preparation method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

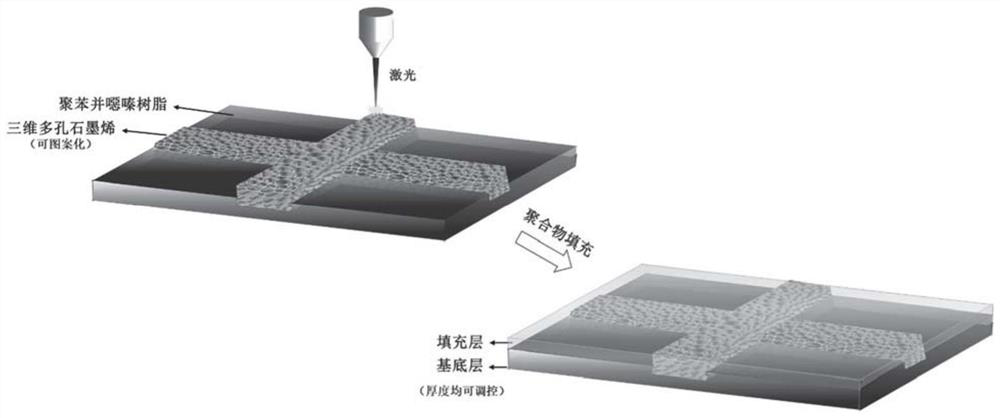

[0031] Specifically, as an aspect of the technical solution of the present invention, it relates to a method for preparing a thermally conductive composite material, which includes the following steps:

[0032] The three-dimensional porous graphene obtained by laser treatment of polybenzoxazine resin is used as a heat conduction path, and then the polymer fluid is cast into the pores contained in the three-dimensional porous graphene, and solidified after removing the solvent and / or raising the temperature to 80-350°C After 5-12 hours, a heat-conducting composite material is obtained.

[0033] In some embodiments of the present invention, specifically, the three-dimensional porous graphene is prepared under the conditions that the laser power is 3-20 W, the laser scanning speed is 60-300 mm / s, and the number of laser scanning is 1-10 times.

[0034] In some embodiments, the laser treatment comprises: at least partial treatment of the polybenzoxazine resin to obtain a partially...

Embodiment 1

[0047] (1) In the control software of the laser engraving system (U.S. Universal, VLS 3.50), set the laser power to 8W, the laser rate to 60mm / s, and the number of laser scans to 2 times, and draw the desired engraving in the control software. Zigzag pattern. Based on the above conditions, the MDA type polybenzoxazine resin is partially laser treated to obtain a grapheneized polybenzoxazine resin, such as figure 1 shown.

[0048] (2) MDA type benzoxazine monomer is dissolved in chloroform to obtain a benzoxazine solution with good fluidity and low viscosity, and then cast it on the polybenzoxazine resin whose surface is grapheneized, After removing the solvent and air bubbles under vacuum conditions, curing at 180, 200 and 220 ° C for 2 h each to obtain a thermally conductive composite material, such as figure 1 shown.

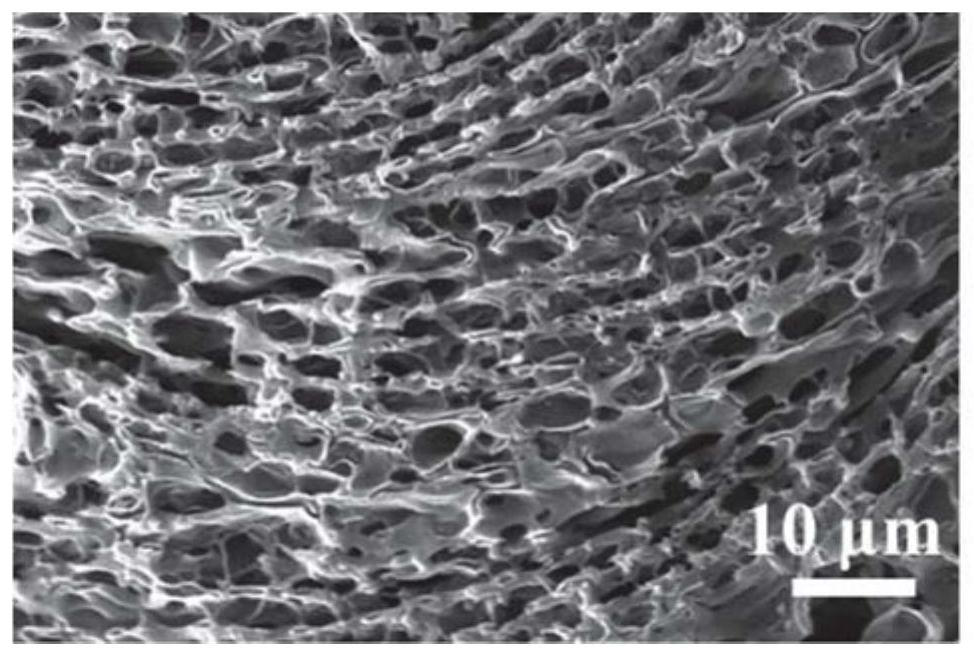

[0049] figure 2 This is the SEM photo of polybenzoxazine resin after laser treatment, showing a three-dimensional porous structure.

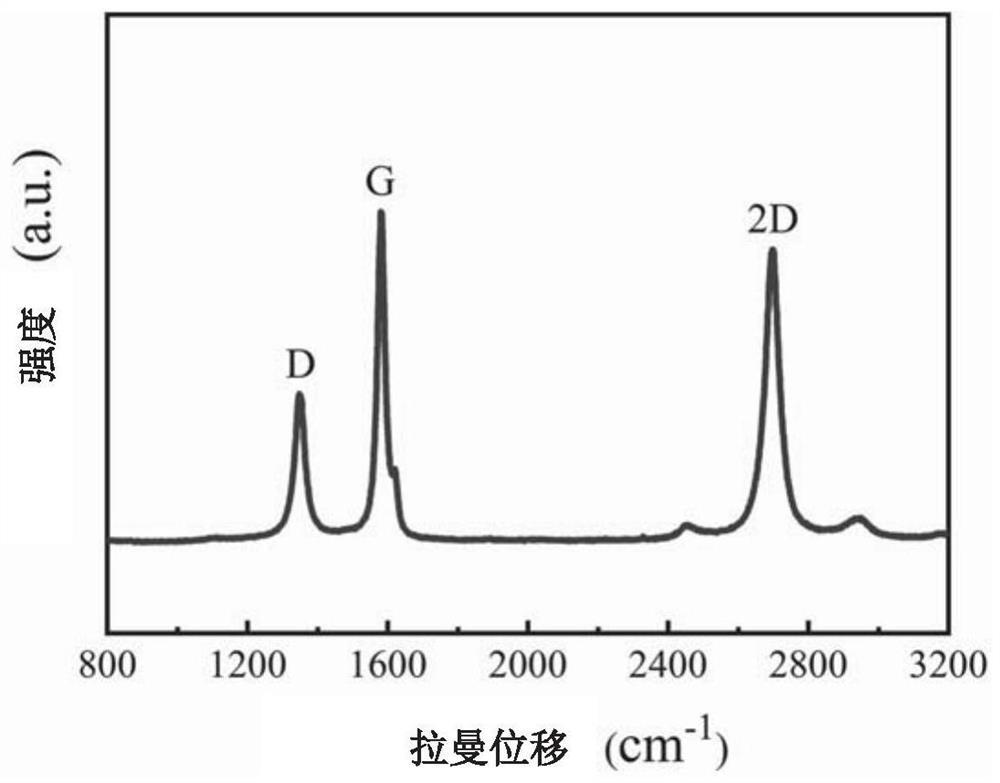

[0050] image 3 I...

Embodiment 2

[0053] (1) Set the laser power to 3W, the laser speed to 150mm / s, and the number of laser scans to 5 times, and draw the desired engraved cross pattern in the control software. Based on the above conditions, the MDA type polybenzoxazine resin was partially laser treated to obtain the polybenzoxazine resin with a graphene surface.

[0054] (2) Cast the mixture of epoxy resin and curing agent on the surface graphenized polybenzoxazine resin, remove the air bubbles under vacuum and cure at 140°C, 160°C and 180°C for 2 hours respectively to obtain a thermally conductive compound Material.

[0055] The prepared thermal conductive composite material has high thermal conductivity in the direction of the cross pattern, and the thermal conductivity is 30W / (m·K). The heat generated by the LED lights radiates to the surroundings in a cross-shaped pattern, indicating the controllability of the heat transfer direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com