A kind of composite nano-coated oil-displacing agent particle and preparation method thereof

An oil-displacing agent and composite technology, which is applied in the field of composite nano-coated oil-displacing agent, can solve the problems of poor salt resistance, temperature resistance and shear resistance, unable to achieve the expected target, low efficiency, etc., and achieves fast reaction speed. , No residue of highly toxic reactants, the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (1) adding the oil-displacing agent to water and ultrasonically, until the oil-displacing agent is completely dissolved to obtain a clear liquid, which is used as the water phase;

[0080] (2) dissolving the coating material in methylene chloride, and adding Span 80, as oil phase;

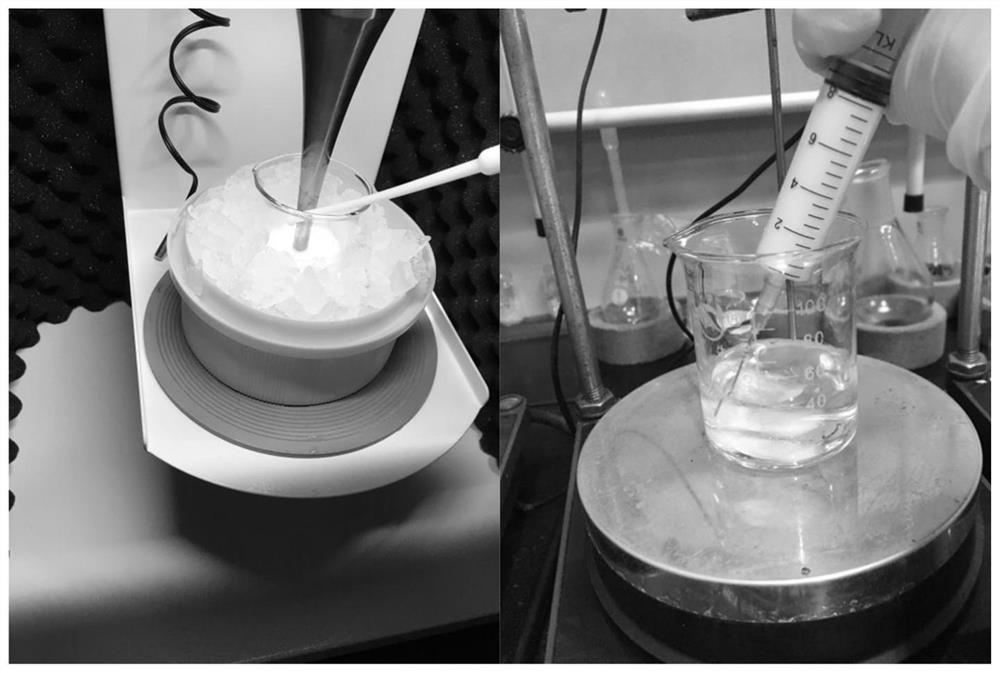

[0081] (3) place the oil phase in an ice bath and use a high-speed disperser to homogenize it, at the same time, use a dropper to drop the water phase into the oil phase, and the dropwise addition ends in 2min, and after the dropwise addition ends, continue to homogenize 3 times, each homogenization time is 3min, after the homogenization is completed, the colostrum is obtained, and the colostrum obtained after homogenization is transferred to an ultrasonic machine for ultrasonication;

[0082] (4) under ice bath condition, add 2wt% PVA aqueous solution dropwise to the colostrum after ultrasonic in step (3) within 3min and carry out ultrasonic at the same time, such as figure 2 wherein, the...

Embodiment 2

[0091] (1) adding the oil-displacing agent to water and ultrasonically, until the oil-displacing agent is completely dissolved to obtain a clear liquid, which is used as the water phase;

[0092] (2) dissolving the coating material in methylene chloride, and adding Span 80, as oil phase;

[0093] (3) place the oil phase in an ice bath and use a high-speed disperser to homogenize it, at the same time, use a dropper to drop the water phase into the oil phase, and the dropwise addition ends in 2min, and after the dropwise addition ends, continue to homogenize 3 times, each homogenization time is 3min, after the homogenization is completed, the colostrum is obtained, and the colostrum obtained after homogenization is transferred to an ultrasonic machine for ultrasonication;

[0094] (4) adding 2wt% PVA aqueous solution dropwise to the sonicated colostrum in step (3) within 3 min under ice bath conditions and performing ultrasonication at the same time; wherein, the sonicated colos...

Embodiment 3

[0103] (1) adding the oil-displacing agent to water and ultrasonically, until the oil-displacing agent is completely dissolved to obtain a clear liquid, which is used as the water phase;

[0104] (2) dissolving the coating material in methylene chloride, and adding Span 80, as oil phase;

[0105](3) place the oil phase in an ice bath and use a high-speed disperser to homogenize it, at the same time, use a dropper to drop the water phase into the oil phase, and the dropwise addition ends in 2min, and after the dropwise addition ends, continue to homogenize 3 times, each homogenization time is 3min, after the homogenization is completed, the colostrum is obtained, and the colostrum obtained after homogenization is transferred to an ultrasonic machine for ultrasonication;

[0106] (4) adding 2wt% PVA aqueous solution dropwise to the sonicated colostrum in step (3) within 3 min under ice bath conditions and performing ultrasonication at the same time; wherein, the sonicated colost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

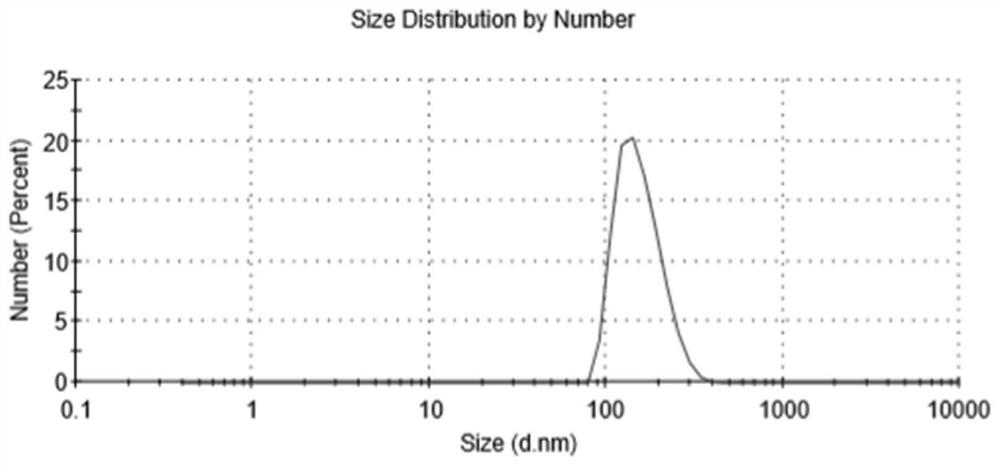

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com