Copper-based pantograph slide plate material obtained through powder hot forging and preparation method thereof

A pantograph sliding plate and hot forging technology, which is applied in the field of powder metallurgy, can solve the problem of not obtaining high-density copper-based composite materials, limiting the development of copper-based pantograph sliding plate materials, and the solid solution ratio of metal components and copper matrix Low-level problems, to achieve the effect of inhibiting material transfer, reducing mechanical abrasion and wear, and no pollution in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

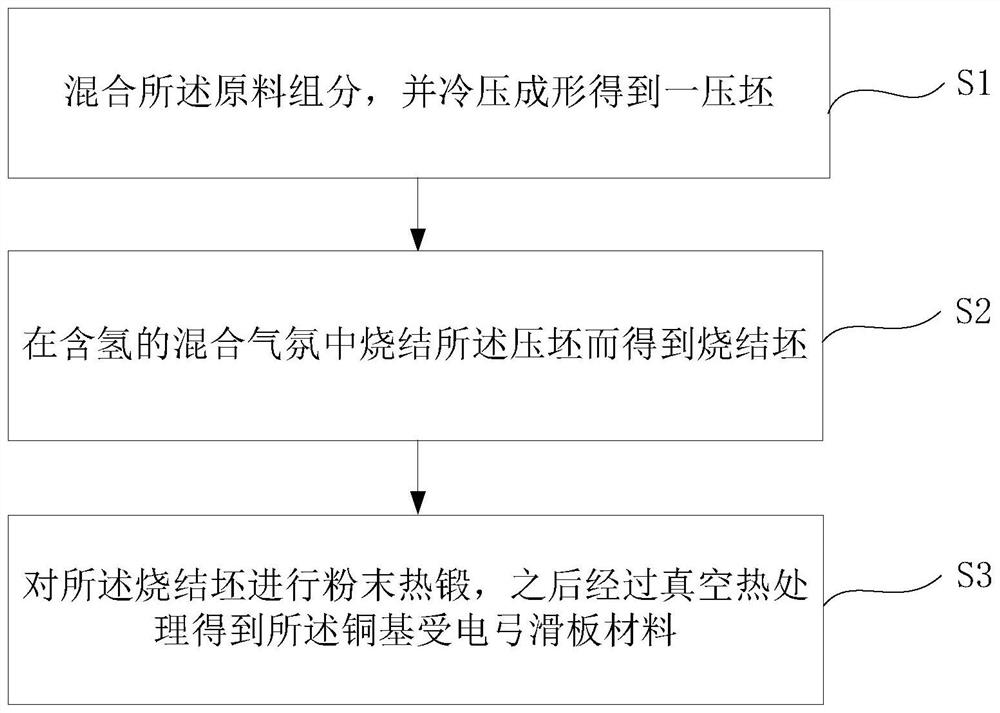

Method used

Image

Examples

Embodiment 1

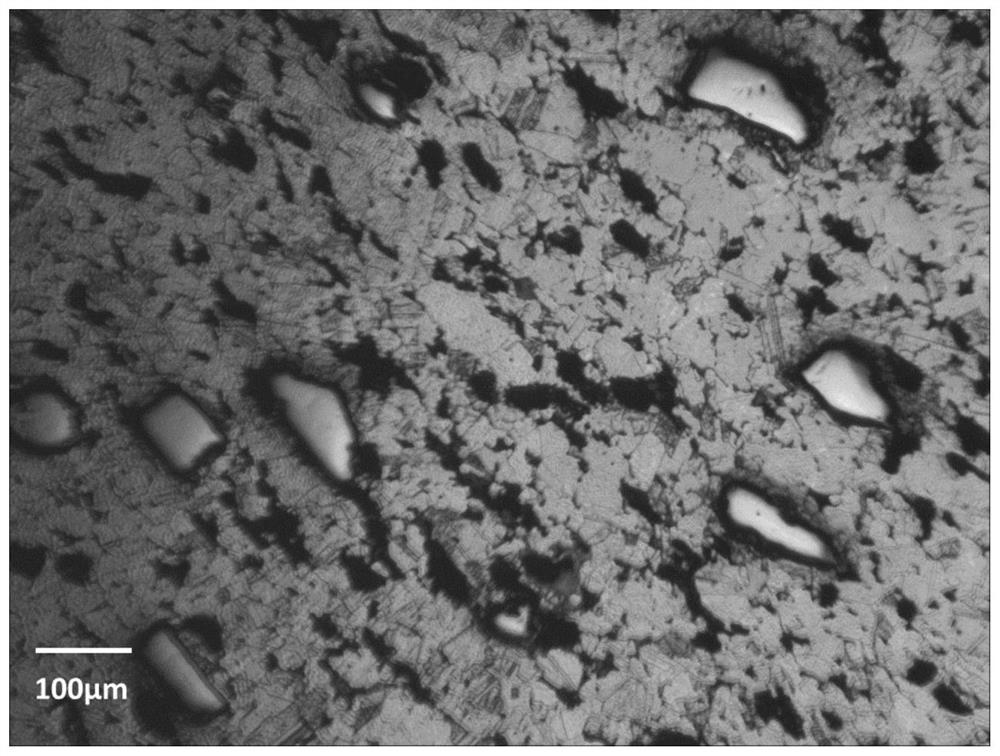

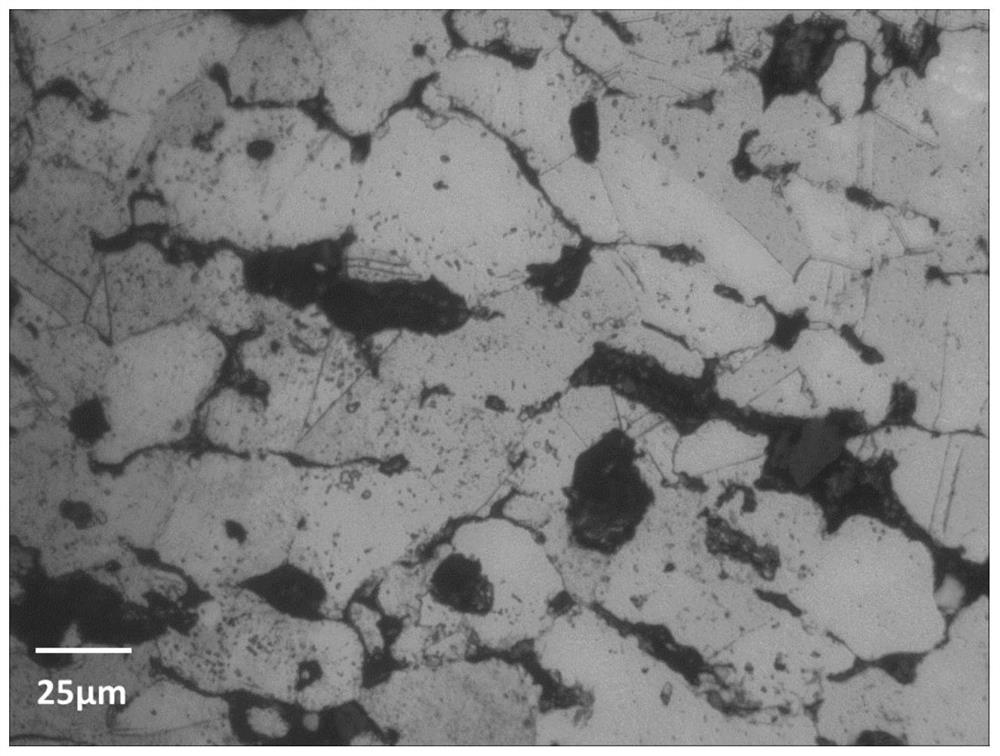

[0040] Take the iron-phosphorus preload powder (17 wt%), iron-nickel pre-gold powder (including 16T%), chromium powder, tin powder, lead powder, and scaly graphic powder are 5% by weight, 6% by weight, 9% by weight, respectively. 1 wt%, 1 wt%, 3 wt%, less than 1 wt% inevitable impurities and the balance of electrolytic copper powder, the particle size is 100 mesh, loaded into the V-type mixer mixed uniform; the resulting mixed powder (granules) The diameter 15 μm) is loaded into the steel mold, and the powder block is obtained by pressing the powder, and then the resulting powder biller is warmed in the sintering furnace of the sintered atmosphere of hydrogen with argon, and the temperature is 870 ° C. 2H. A sintered body; in addition, the forging mold is heated to 300 ° C, the burning blank is heated to 800 ° C, and the sintered body is moved into the forging mold in 5 seconds, at 1.8x10 3 KJ / M 2 Heat forging mining under the energy density, wherein the initial forging temperat...

Embodiment 2

[0046] Take the iron-phosphorus compound (containing phosphorus 18 wt%), iron-nickel predecessor (including 17 wt%), chromium powder, tin powder, lead powder, and scaly graphic powder, 5 wt%, 6 wt%, 8 wt%, respectively, 1 wt%, 1 wt%, 3 wt%, less than 1% by weight of inevitable impurities and the balance of electrolytic copper powder, the particle size is -80 mesh, mixed into the V-type mixer; mix the powder (particle size) 50 μm) is loaded into the steel mold, and the powder block is obtained by pressing the powder, and then the powder biller is heated in a sintering furnace of the sintered atmosphere of hydrogen and argon, and the temperature is 10 ° C / min, at the temperature 870 ° C insulation for 2 h, gains the sintered body; heating the forging mold to 300 ° C, the sintered body is heated to 750 ° C, move the sintered body into the forging in 5 seconds, at 1.8x10 3 KJ / M 2 Heat forging mining under the energy density, wherein the initial forging temperature is 750 ° C, and ...

Embodiment 3

[0049]Take the iron-phosphorus-phosphorus-phosphorus and phosphorus, iron-nickel predecessor (containing nickel 18 wt%), chromium powder, tin powder, lead powder, and scaly graphic powder are 5 wt%, 6 wt%, 7 wt%, respectively, 1 wt%, 1 wt%, 3 wt%, less than 1 wt% inevitable impurities and the balance of electrolytic copper powder, the particle size is 40 mesh, mixed in a V-shaped mixture; mixed powder (particle size) 30 μm) is loaded into the steel mold, and the powder block is obtained by pressing the powder, and then the powder billet is heated in a sintering furnace of a mixed gas of hydrogen and argon, and the temperature is 10 ° C / min, at temperature 870 ° C insulation for 2 h, gains the sintered body; heat the mold to 300 ° C, the sintered body is heated to 700 ° C, in 5 seconds, move the sintered body into the forging die, at 1.8x10 3 KJ / M 2 The energy density is hot forged, the initial forging temperature is 700 ° C, and the final temperature is 450 ° C. After air cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com