A copper-based pantograph sliding plate material hot forged by powder and its preparation method

A pantograph sliding plate and hot forging technology, which is applied in the field of powder metallurgy, can solve the problem of not obtaining high-density copper-based composite materials, limiting the development of copper-based pantograph sliding plate materials, and the solid solution ratio of metal components and copper matrix Low-level problems, to achieve the effect of inhibiting material transfer, reducing mechanical abrasion and wear, and no pollution in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

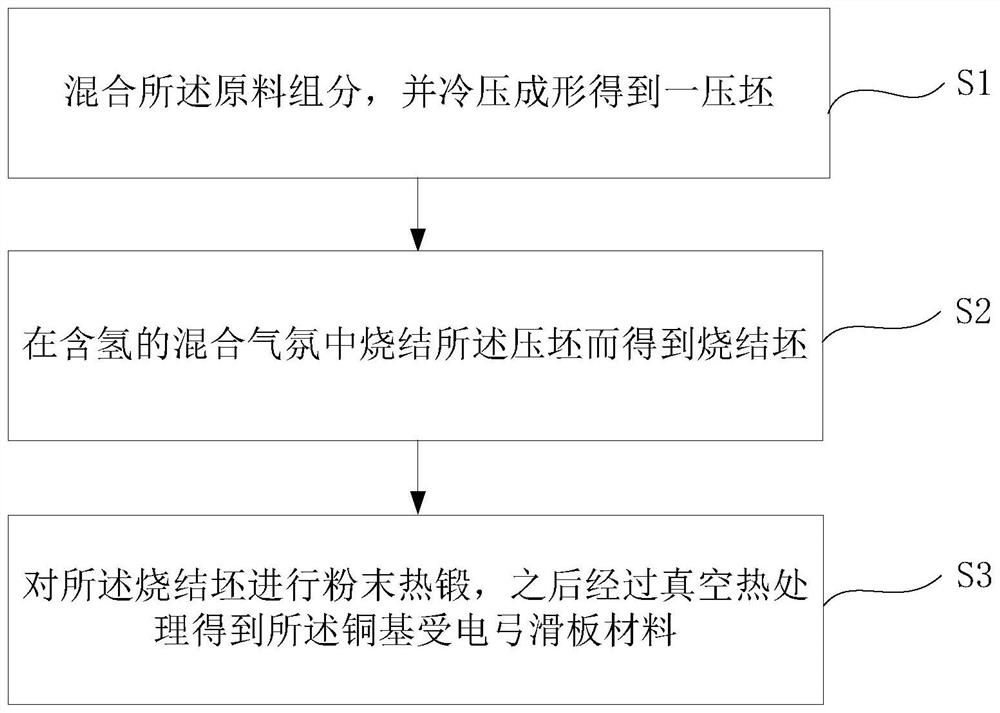

Method used

Image

Examples

Embodiment 1

[0040] Take by weighing iron-phosphorus prealloy powder (containing phosphorus 17wt%), iron-nickel prealloy powder (containing nickel 16t%), chromium powder, tin powder, lead powder, flake graphite powder are respectively 5wt%, 6wt%, 9wt% , 1wt%, 1wt%, 3wt%, less than 1wt% unavoidable impurities and the electrolytic copper powder of the remainder, the particle diameter is 100 orders, put into V-shaped mixer and mix uniformly; 15 μm in diameter) into a steel mold, pressed and demolded to obtain a powder compact, and then the obtained powder compact is heated up in a sintering furnace whose sintering atmosphere is a mixed gas of hydrogen and argon, and kept at a temperature of 870°C for 2 hours. Obtain a sintered body; in addition, heat the forging mold to 300°C, heat the sintered body to 800°C, and move the sintered body into the forging mold within 5 seconds, at 1.8x10 3 kJ / m 2 Hot forging densification is carried out under energy density, in which the initial forging tempera...

Embodiment 2

[0046] Take by weighing iron-phosphorus alloy powder (containing phosphorus 18wt%), iron-nickel prealloy powder (containing nickel 17wt%), chromium powder, tin powder, lead powder, flake graphite powder are respectively 5wt%, 6wt%, 8wt%, 1wt%, 1wt%, 3wt%, less than 1wt% unavoidable impurities and the electrolytic copper powder of the remainder, the particle diameter is -80 mesh, put into the V-shaped mixer and mix evenly; mix the powder (particle diameter 50 μm) into a steel mold, and the powder compact was obtained by pressing and demolding, and then the powder compact was heated in a sintering furnace whose sintering atmosphere was a mixture of hydrogen and argon, with a heating rate of 10°C / min. Heat at 870°C for 2 hours to obtain a sintered body; heat the forging mold to 300°C, heat the sintered billet to 750°C, and move the sintered body into the forging mold within 5 seconds. 3 kJ / m 2 Hot forging densification is carried out under energy density, where the initial forgi...

Embodiment 3

[0049]Take by weighing iron-phosphorus alloy powder (containing phosphorus 19wt%), iron-nickel prealloy powder (containing nickel 18wt%), chromium powder, tin powder, lead powder, flake graphite powder are respectively 5wt%, 6wt%, 7wt%, 1wt%, 1wt%, 3wt%, less than 1wt% unavoidable impurity and the electrolytic copper powder of surplus, particle diameter is 40 orders, puts into V-type mixer and mixes uniformly; Mix powder (particle diameter 30 μm) into a steel mold, and the powder compact was obtained by pressing and demolding, and then the powder compact was heated in a sintering furnace whose sintering atmosphere was a mixture of hydrogen and argon, with a heating rate of 10°C / min. Heat at 870°C for 2 hours to obtain a sintered body; heat the mold to 300°C, heat the sintered body to 700°C, and within 5 seconds, move the sintered body into the forging die, 3 kJ / m 2 Hot forging is carried out under energy density, the initial forging temperature is 700°C, the final forging tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com