Textile processing equipment capable of reducing dye liquor impurities and improving quality of printed and dyed cloth

A technology of processing equipment and impurities, applied in the field of textile processing equipment, can solve the problems of difficulty in meeting the needs of fast-paced textile printing and dyeing processing, easily affecting the quality of textile printing and dyeing processing, and impurity cannot be removed in time, so as to improve the filtering effect and avoid mesh clogging. , the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

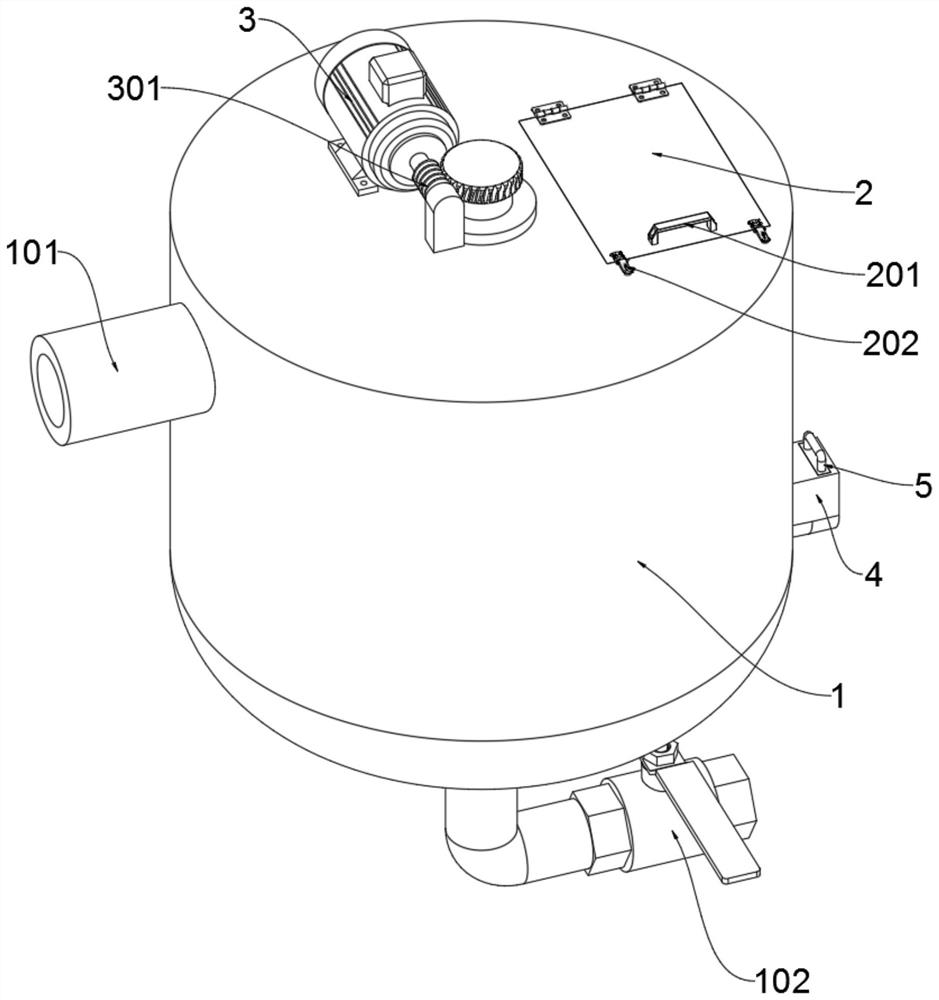

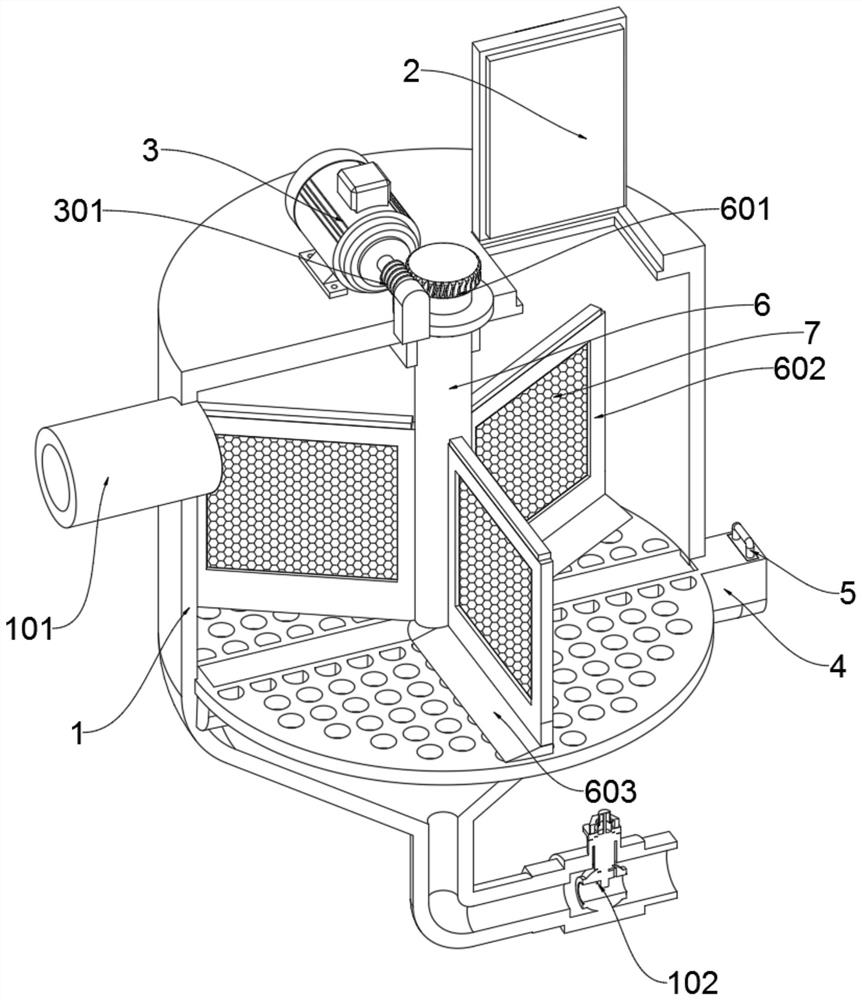

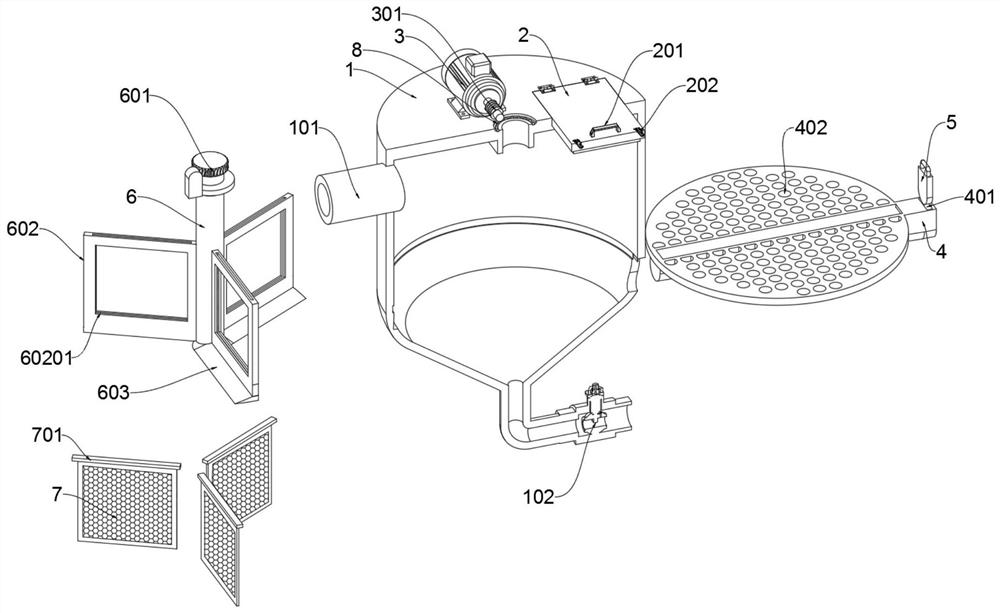

[0028] as attached figure 1 to attach Figure 6 Shown:

[0029] The present invention provides a textile processing equipment for reducing dye liquor impurities and improving the quality of printed and dyed cloth, which includes a filter barrel 1; a slag discharge tank 4 is arranged through the left and right sides of the filter barrel 1, and the right end of the slag discharge tank 4 is slidably connected with a slag tank stopper Plate 5; the top right side hinge of filter bucket 1 is connected with inspection door 2, and the length of inspection door 2 is identical with the length of filter screen 7, and the front end of inspection door 2 top is provided with door handle 201, and the left and right sides of door handle 201 are provided with There is a convenient lock 202. When in use, open the convenient lock 202, then pull the door handle 201 and pull it backwards, the inspection door 2 can be opened, and the filter screen in the filter barrel 1 can be checked through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com