Sealing and water stopping structure applied to high-water-pressure unconsolidated stratum shield tunnel receiving tunnel portal and construction method

A shield tunneling, sealing and water-stopping technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of cement being easily taken away, water gushing and sand gushing, etc., and achieve simplified construction procedures, large engineering quantities, and high costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

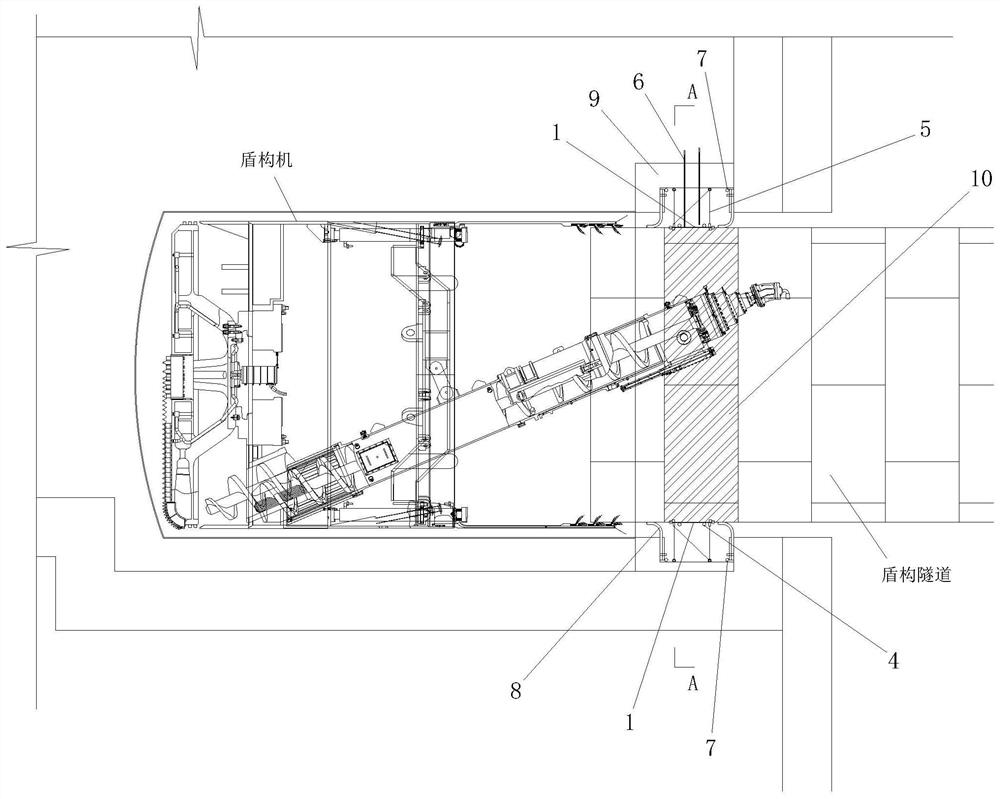

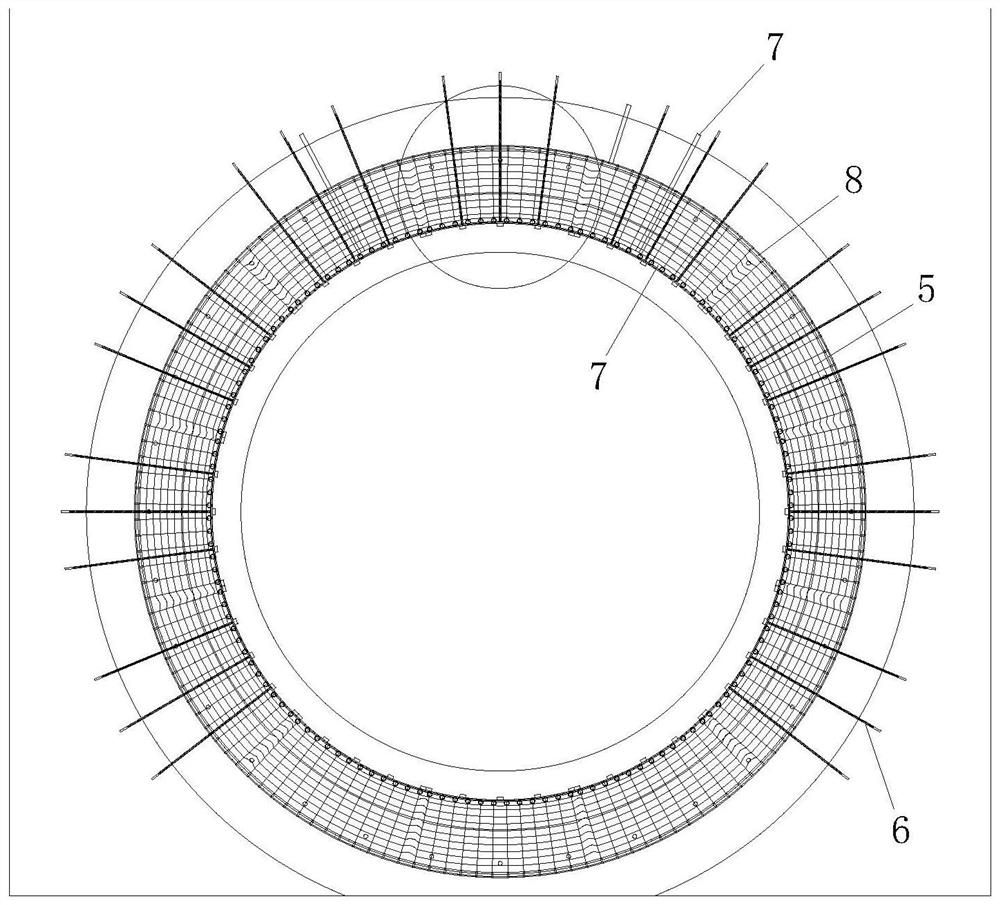

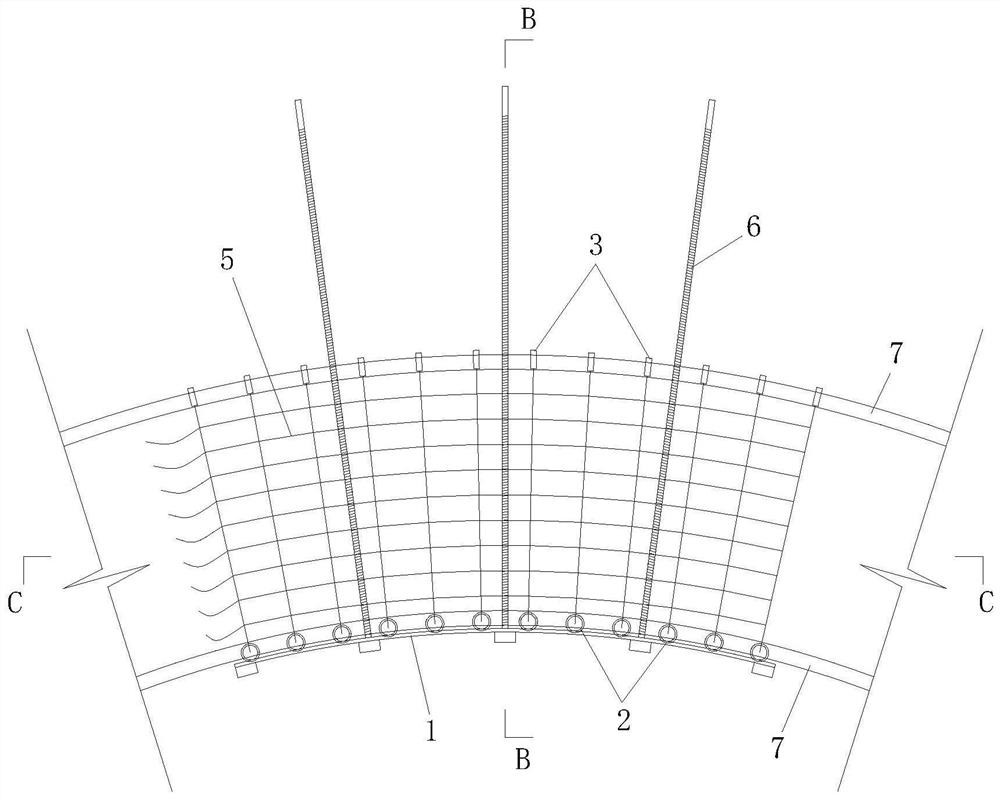

[0035] In this example, refer to Figure 1-Figure 5 , the sealing water-stop structure applied to the receiving portal of the shield tunnel in loose ground with high water pressure, the water-stop structure is a concrete water-stop structure, which is arranged between the (special) steel pipe sheet 10 and the externally extending ring beam 9 of the portal In the annular space between the tunnels, the annular space, the ring beam 9 extending outside the portal and the steel pipe sheet 10 are all the structures of the shield tunnel itself, and the specific formation process will not be repeated here;

[0036] The water-stop structure includes a base plate 1, an inner fixed ring 2, an outer fixed ring 3, a circumferential tightening cable 4 and a force-pressing screw 6, and the outer fixed ring 3 is pre-embedded in the externally extending ring beam 9 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com