Efficient submerged combustion type gasifier

A submerged combustion and gasifier technology, applied in pressure vessels, heat storage heaters, non-pressure vessels, etc., can solve the problems of poor sealing of cover plates, low heat exchange efficiency, and poor anti-corrosion effect, and achieve Prevent corrosion of panels, improve heat exchange efficiency, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

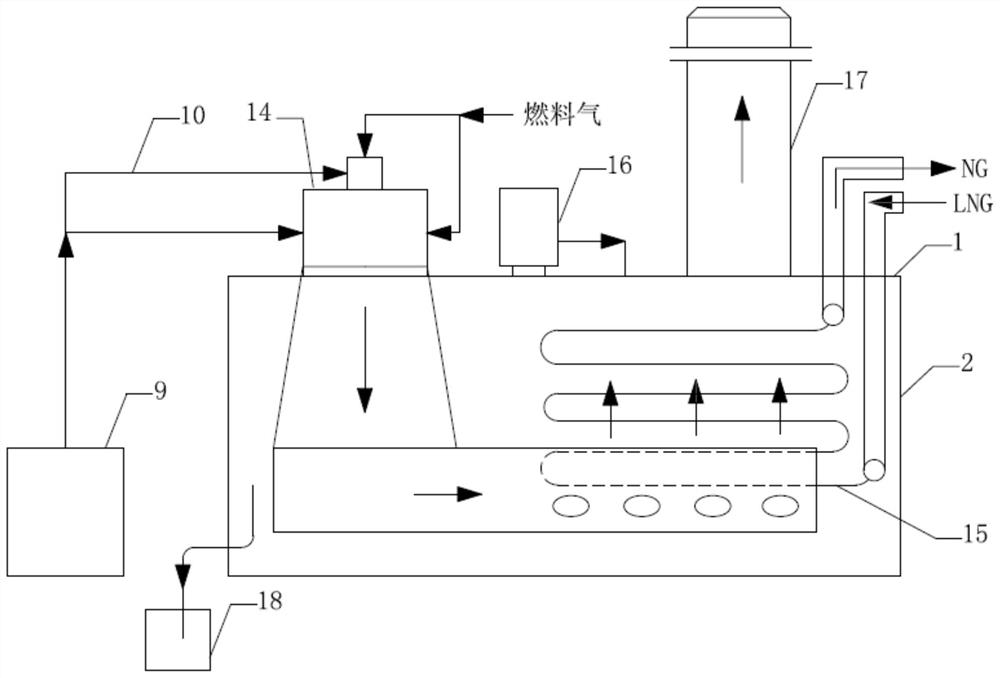

[0042] Such as figure 1 As shown, a high-efficiency submerged combustion gasifier includes a blower 9, an air duct 10, a burner 14, a water bath 2, a heat exchange tube bundle 15, an lye tank 16, a chimney 17, an overflow pool 18, and a water bath A sealing cover plate; the heat exchange tube bundle 15 is a high-efficiency heat exchange tube bundle composed of smooth tubes, and the material of the heat exchange tubes is stainless steel.

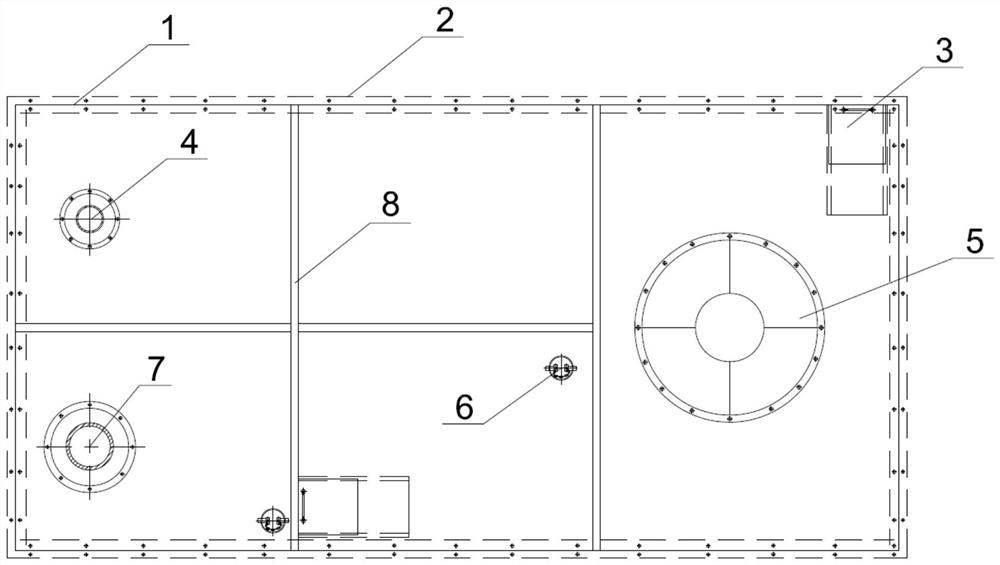

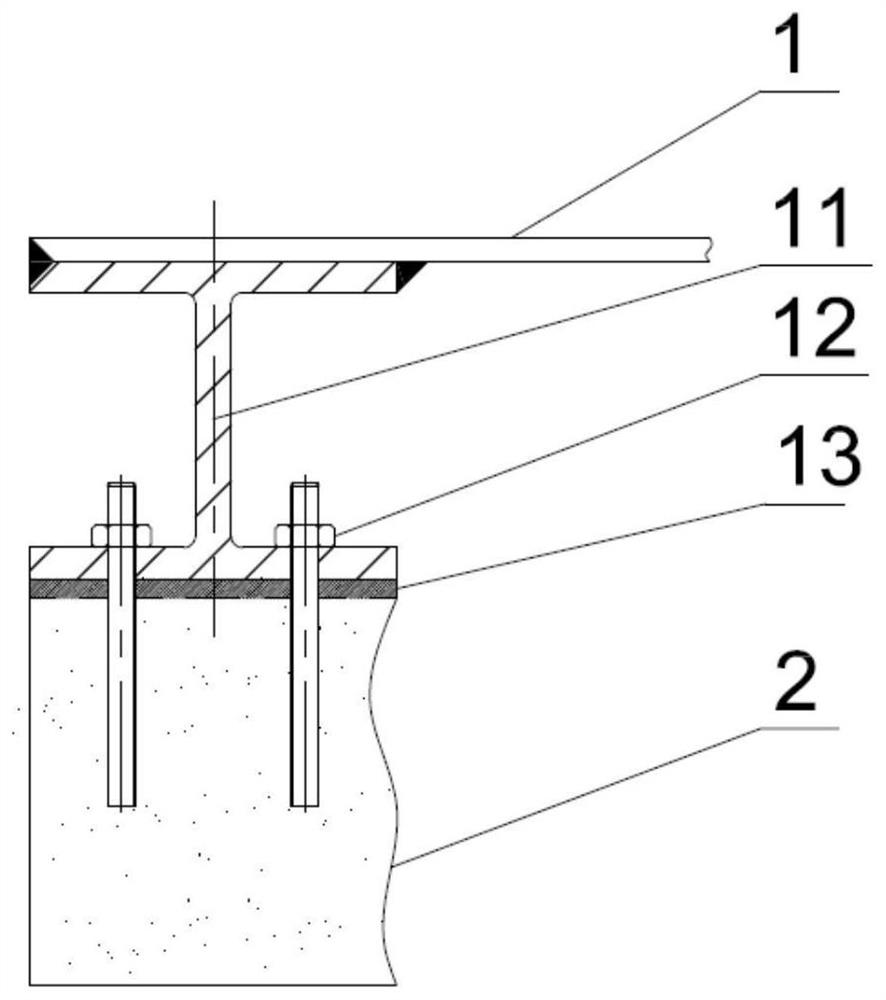

[0043] Such as Figure 2-Figure 9 As shown, the sealing cover plate for the water bath includes a panel 1, and the panel 1 is formed by splicing five patterned steel plates, leaving a gap with a width of 5-20 mm at the joint of two adjacent patterned steel plates. The lower surfaces of two adjacent checkered steel plates are provided with base plates 81 to form drains 8, and rubber gaskets are arranged between the lower surfaces of checkered steel plates and base plates 81. The base plates 82 are fixed to the checkered steel plates by bolts,...

Embodiment 2

[0053] On the basis of Embodiment 1, adjustment: the lower part of the edge of the observation hole 6 stretches out so that the edge of the observation hole 6 is stepped, and the upper part of the edge of the observation hole cover plate 61 stretches out so that the observation hole cover plate is stepped. The hole cover plate 61 is overlapped with the panel 1 .

Embodiment 3

[0055] The heat exchange tube bundle is a high-efficiency heat exchange tube bundle composed of corrugated tubes, and the material of the heat exchange tubes is stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com