Mixture moisture detection value correction method based on feedback adaptive prediction model

A mixture moisture, self-adaptive prediction technology, applied in neural learning methods, biological neural network models, measuring devices, etc., can solve the problems of out-of-control moisture data, large impact, and inability to completely solve existing technical problems, so as to reduce losses , Solve the effect of too many input parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

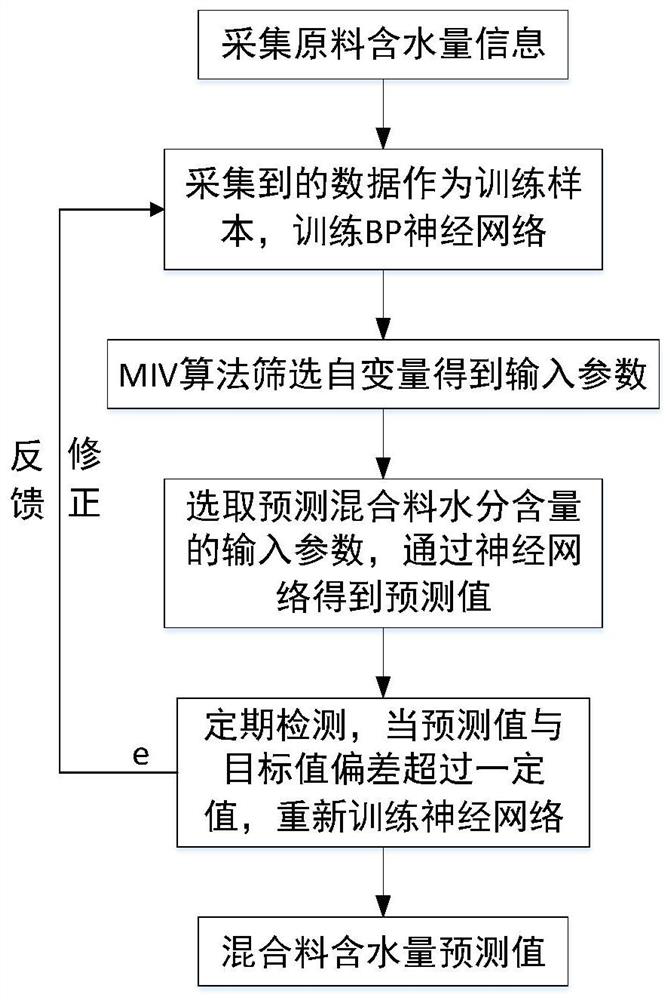

[0050] Embodiment 1: see Figure 1-Figure 5 , a method for correcting the moisture detection value of a mixture based on a feedback adaptive prediction model, said method comprising the following steps:

[0051] Step 1: Collect moisture content information of raw materials,

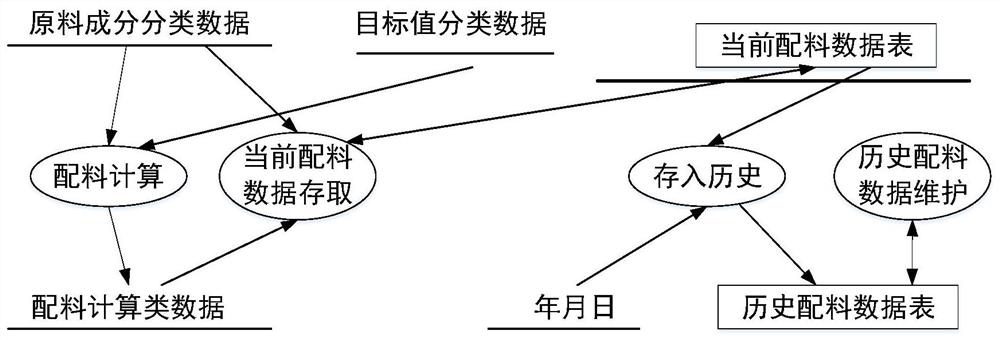

[0052] Step 2: Calculate the moisture content of the mixture through the ingredient calculation system,

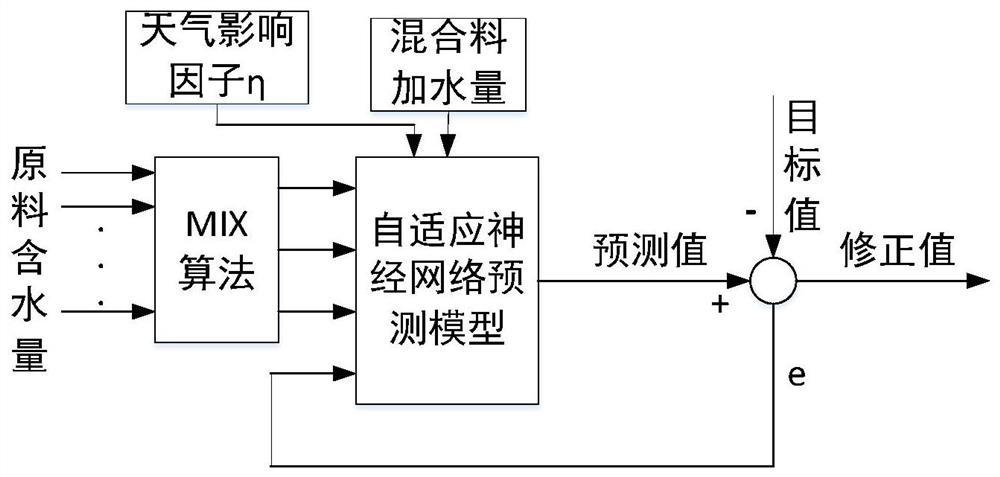

[0053] Step 3: The MIV algorithm screens the model input, uses the collected samples to train the BP neural network, and the trained adaptive neural network system predicts the moisture value of the mixture and corrects it, and compares the predicted value with the target value at regular intervals. If the deviation exceeds a certain value, the feedback correction is performed.

[0054] Step 1: Collect moisture content information of raw materials, as follows:

[0055] The sintering raw material composition information of the sintering ore is provided by the sintering site staff, including the mixe...

Embodiment 2

[0108] Such as Figure 5As shown, the mixed material moisture prediction and correction system of the present invention mainly includes three parts, data display, moisture prediction and correction, and system management. The data display part includes the display of real-time data, water addition data and sample data, as well as the query and download of historical data. The moisture prediction and correction part is to train the neural network through the sample, input the variables screened by the MIV algorithm into the trained neural network, output the predicted value of the mixture moisture, compare it with the target value, feed back the difference to the input, and re-adjust the process . The system management part is to manage the data in the moisture prediction and correction process, including algorithm management, log management and authority management.

[0109] The present invention breaks through the previous research scope of the sintering mixture detection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com