Heart mitral valve mechanical property optimization method, system and equipment

A technology of mitral valve mechanics and optimization method, which is applied in the field of mechanical performance optimization of the cardiac mitral valve, which can solve the problems of inability to evaluate the surgical plan and the inability to personalize the design of the artificial valve ring, and achieve the improvement of stress concentration and the maximum stress Effect of reduced strain and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to illustrate the technical solutions of the present invention more clearly, the technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only part of the embodiments of the present invention. All other embodiments obtained without creative work shall belong to the scope of the present invention.

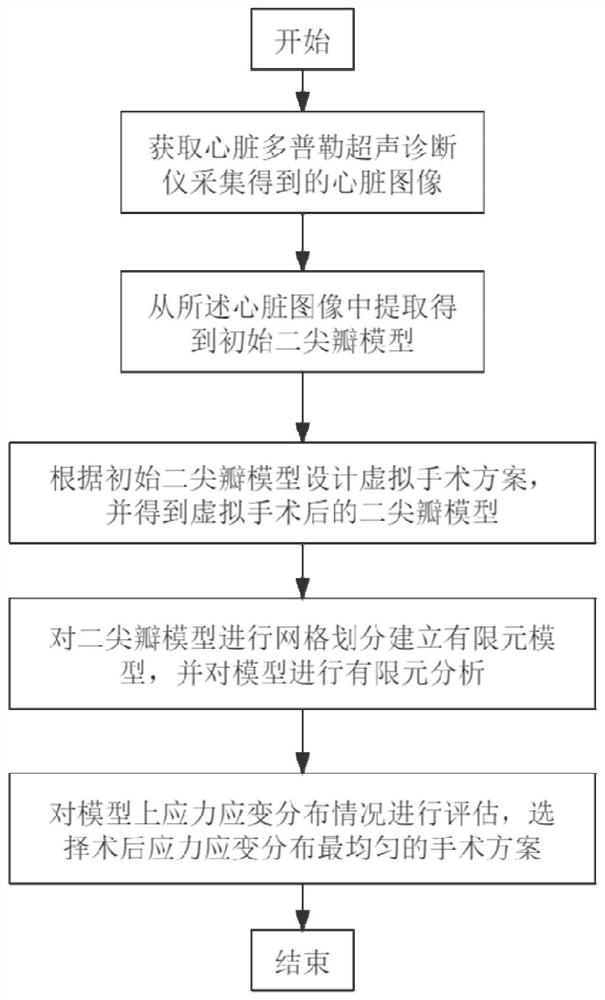

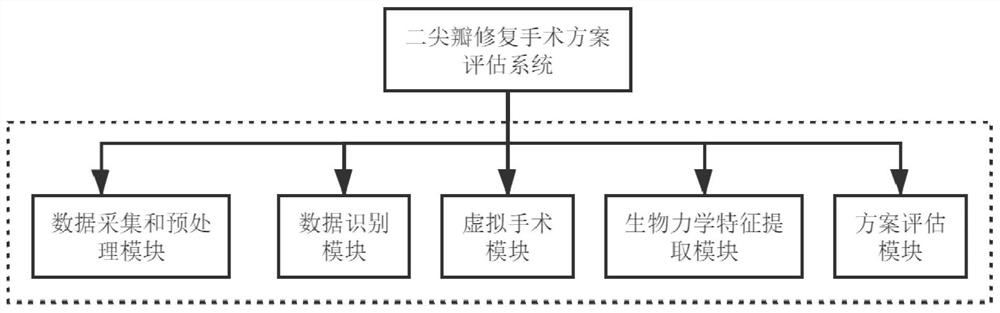

[0046] please participate figure 1 , the present invention provides a method for optimizing the mechanical properties of a cardiac mitral valve, the steps comprising:

[0047] Step 1. Acquire cardiac ultrasound image data of the patient.

[0048] In one embodiment of the present invention, the patient's medical image data is collected using a transesophageal ultrasonic diagnostic instrument to obtain RT3D-TEE (real-time three-dimensional transesophageal echocardiography), and the patient's data is saved in DICOM format.

[0049] Step 2, importing the patient's cardiac ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com