Fuel cell partition composite board and forming device and method thereof

A fuel cell and molding device technology, applied in the direction of fuel cells, circuits, electrical components, etc., to achieve the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

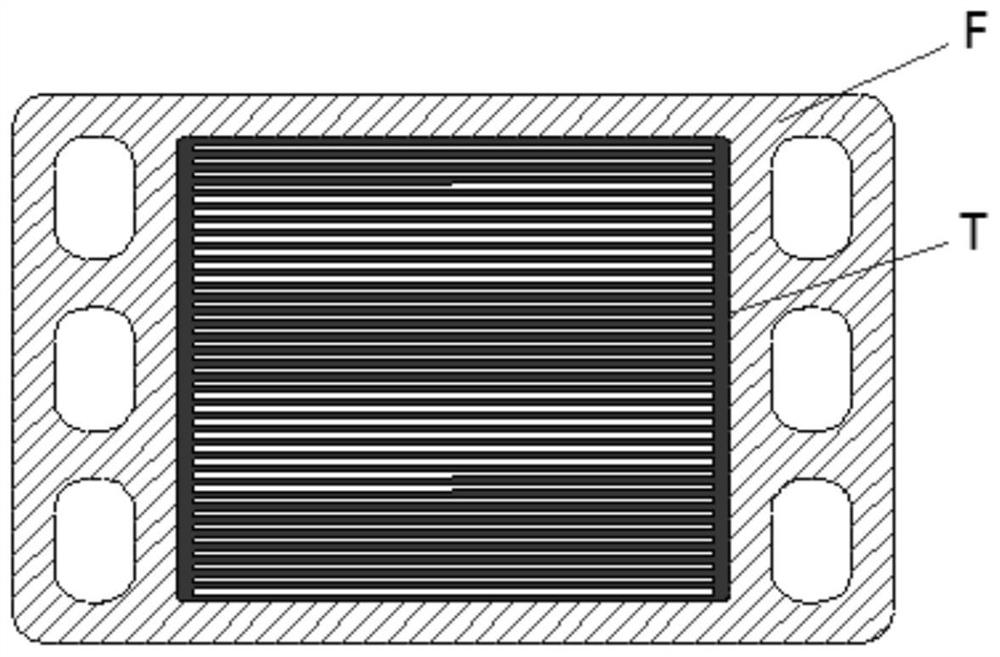

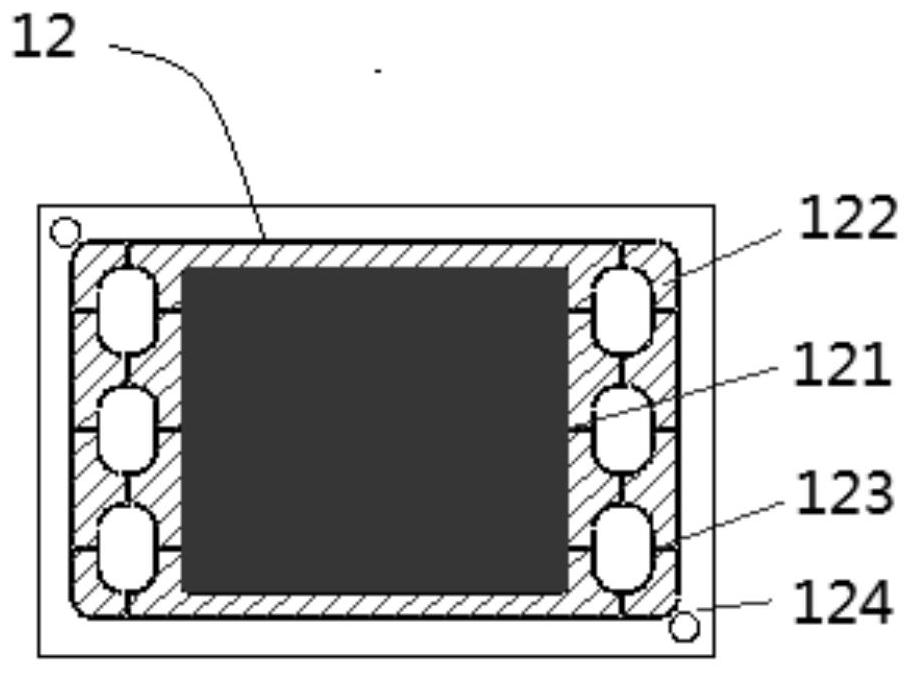

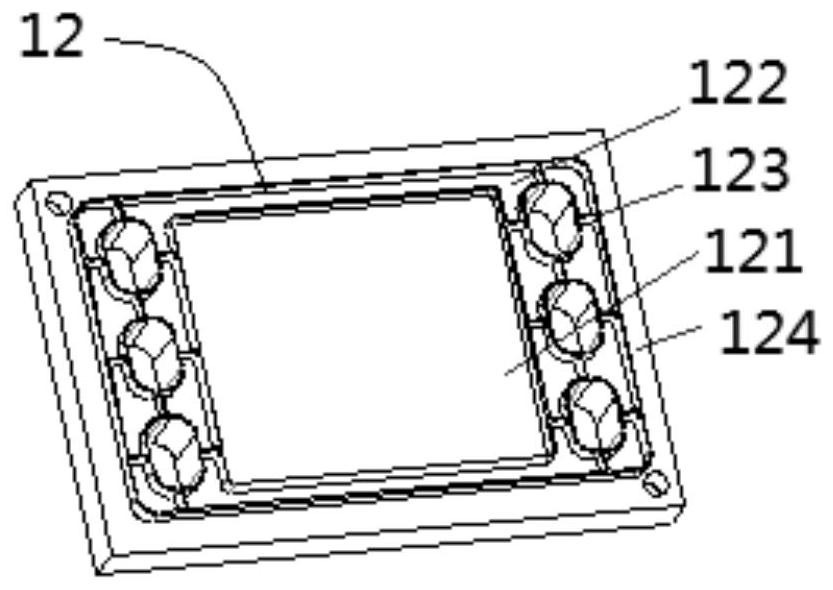

[0042] A partitioned composite plate for a fuel cell. According to the characteristics of the fuel cell plate, the plate is divided into a reaction zone and a non-reaction zone, and two powders with different formulations are used as the fuel cell plate reaction zone and non-reaction zone. The raw material is molded by mold molding, and the formed composite board includes a reaction zone composite board and a non-reaction zone composite board, wherein the reaction zone composite board powder A formula includes the following components by weight: 70 parts of graphite powder, 5 parts of carbon fiber part, 20 parts of resin, 5 parts of conductive carbon black;

[0043] The formula B of the raw material powder B of the composite plate in the non-reaction zone includes the following components in parts by weight: 10 parts of graphite powder, 10 parts of short carbon fiber, and 80 parts of resin.

[0044] To make the above-mentioned reaction zone and non-reaction zone integrally for...

Embodiment 2

[0056] A partitioned composite board for a fuel cell, including a composite board in a reaction zone and a composite board in a non-reaction zone, wherein the powder formula of the composite board in the reaction zone includes the following components in parts by weight: 60 parts of graphite powder, 8 parts of carbon fiber, 25 parts of resin, and conductive carbon black 8 parts;

[0057] The non-reaction zone composite plate powder formula includes the following components by weight: 5 parts of graphite powder, 5 parts of short carbon fiber, and 90 parts of resin.

[0058] All the other are with embodiment 1.

Embodiment 3

[0060] A partitioned composite board for a fuel cell, including a composite board in a reaction zone and a composite board in a non-reaction zone, wherein the powder formula of the composite board in the reaction zone includes the following components in parts by weight: 80 parts of graphite powder, 1 part of carbon fiber, 15 parts of resin, and conductive carbon 1 part black;

[0061] The non-reaction zone composite plate powder formula includes the following components by weight: 15 parts of graphite powder, 15 parts of short carbon fiber, and 70 parts of resin.

[0062] All the other are with embodiment 1.

[0063] The pole plate gained in the above-mentioned embodiment is carried out performance test, and the results are as follows:

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com