Snakelike flow field structure

A serpentine and flow field technology, which is applied in the field of fuel cells, can solve the problems that products cannot be discharged in time, heat cannot be dissipated in time, and battery performance is degraded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

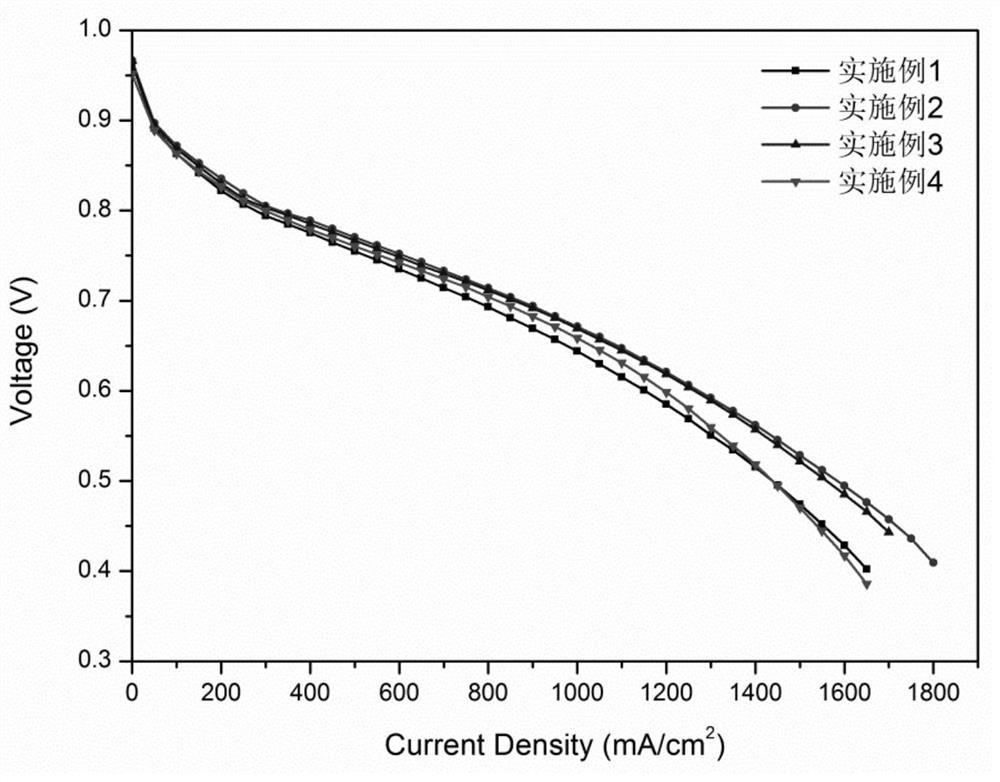

Embodiment 1

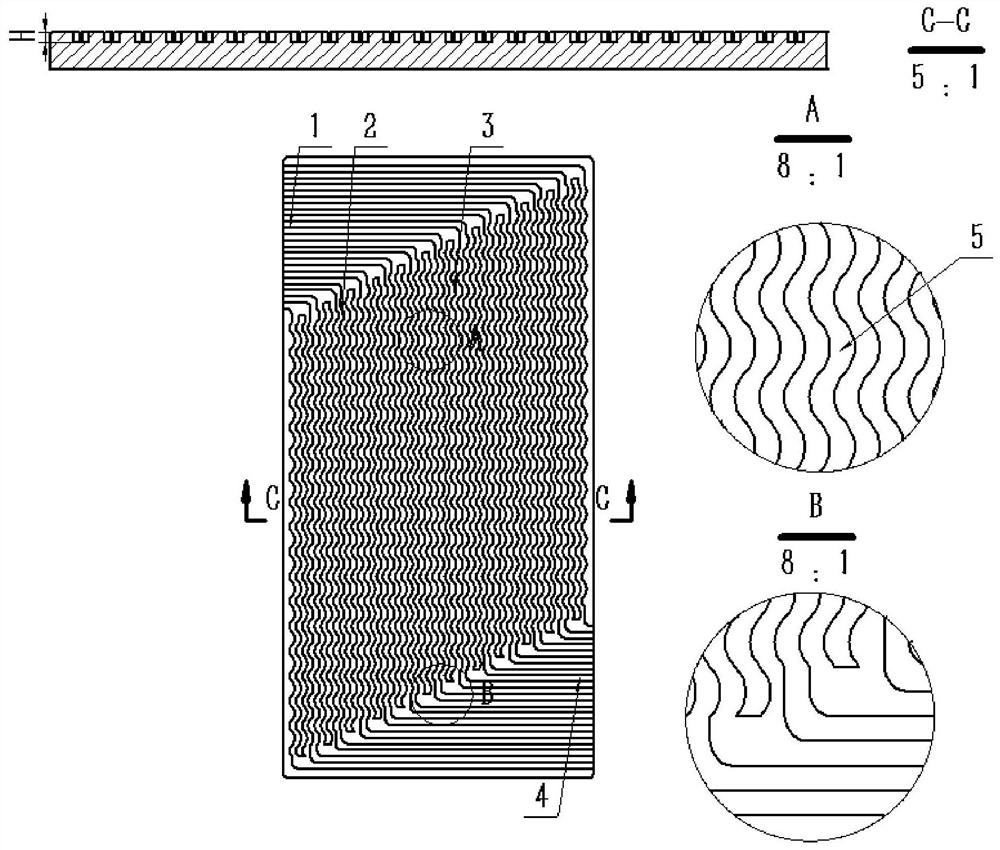

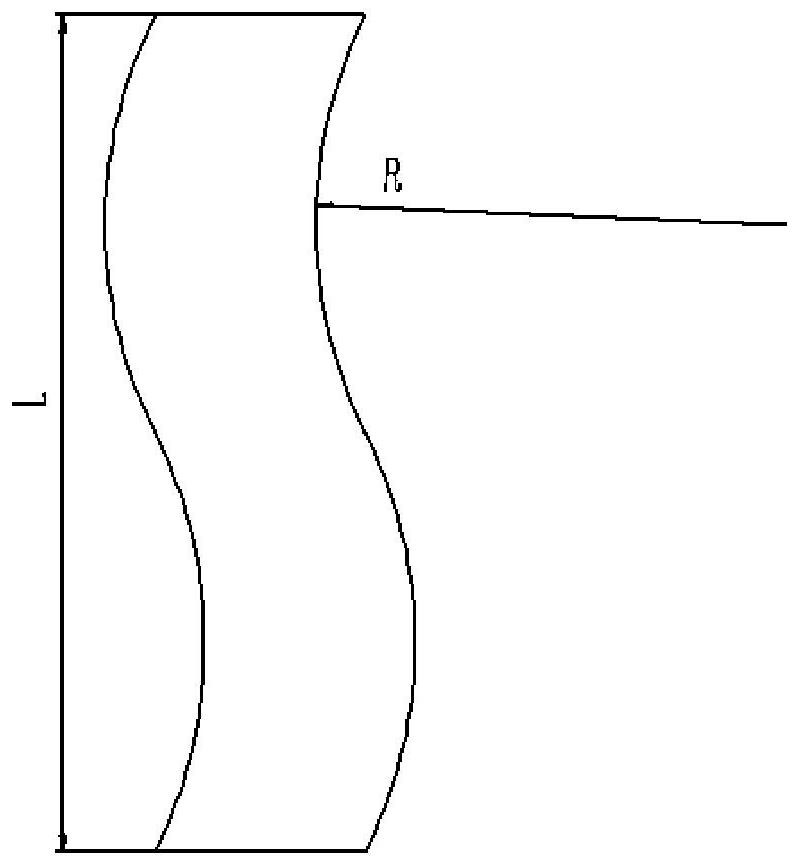

[0027] A serpentine flow field structure, the central area of the flow field structure is provided with a plurality of serpentine ridges II2, the plurality of serpentine ridges II2 are arranged in parallel, and the serpentine ridge II2 is composed of a plurality of s-shaped units 5 at the head and tail Connecting structure, the linear distance L between the two ends of the s-shaped unit 5 is 2mm, the arc radius R of the s-shaped unit 5 is 2mm, the height H of the s-shaped unit 5 is 0.4mm and each The heights H of the s-shaped units 5 are all the same, and a serpentine gas flow channel 3 is formed between adjacent serpentine ridges II2;

[0028] The flow field structure is provided with a plurality of ridges I1, and the plurality of ridges I1 are arranged in parallel, and a gas inlet channel is formed between adjacent ridges I1, and the gas inlet channel communicates with the serpentine gas flow channel 3;

[0029] The flow field structure is provided with a plurality of ridg...

Embodiment 2

[0032] A serpentine flow field structure, the central area of the flow field structure is provided with a plurality of serpentine ridges II2, the plurality of serpentine ridges II2 are arranged in parallel, and the serpentine ridge II2 is composed of a plurality of s-shaped units 5 at the head and tail connected, the linear distance L between the two ends of the s-shaped unit 5 is 2 mm, the arc radius R of the s-shaped unit 5 is 1.5 mm, the height H of the s-shaped unit 5 is 0.4 mm, and each The height H of each s-shaped unit 5 is the same, and a serpentine gas flow channel 3 is formed between adjacent said serpentine ridges II2;

[0033] The flow field structure is provided with a plurality of ridges I1, and the plurality of ridges I1 are arranged in parallel, and a gas inlet channel is formed between adjacent ridges I1, and the gas inlet channel communicates with the serpentine gas flow channel 3;

[0034] The flow field structure is provided with a plurality of ridges III...

Embodiment 3

[0037] A serpentine flow field structure, the central area of the flow field structure is provided with a plurality of serpentine ridges II2, the plurality of serpentine ridges II2 are arranged in parallel, and the serpentine ridge II2 is composed of a plurality of s-shaped units 5 at the head and tail Connecting structure, the linear distance L between the two ends of the s-shaped unit 5 is 4mm, the arc radius R of the s-shaped unit 5 is 1.5mm, the height H of the s-shaped unit 5 is 0.4mm and each The height H of each s-shaped unit 5 is the same, and a serpentine gas flow channel 3 is formed between adjacent said serpentine ridges II2;

[0038] The flow field structure is provided with a plurality of ridges I1, and the plurality of ridges I1 are arranged in parallel, and a gas inlet channel is formed between adjacent ridges I1, and the gas inlet channel communicates with the serpentine gas flow channel 3;

[0039] The flow field structure is provided with a plurality of rid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com