Waste water denitrification nitrogen removal reactor

A denitrification and reactor technology, applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc., can solve the problems of easy clogging and high energy consumption, and achieve clogging prevention, energy consumption reduction and mass transfer good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

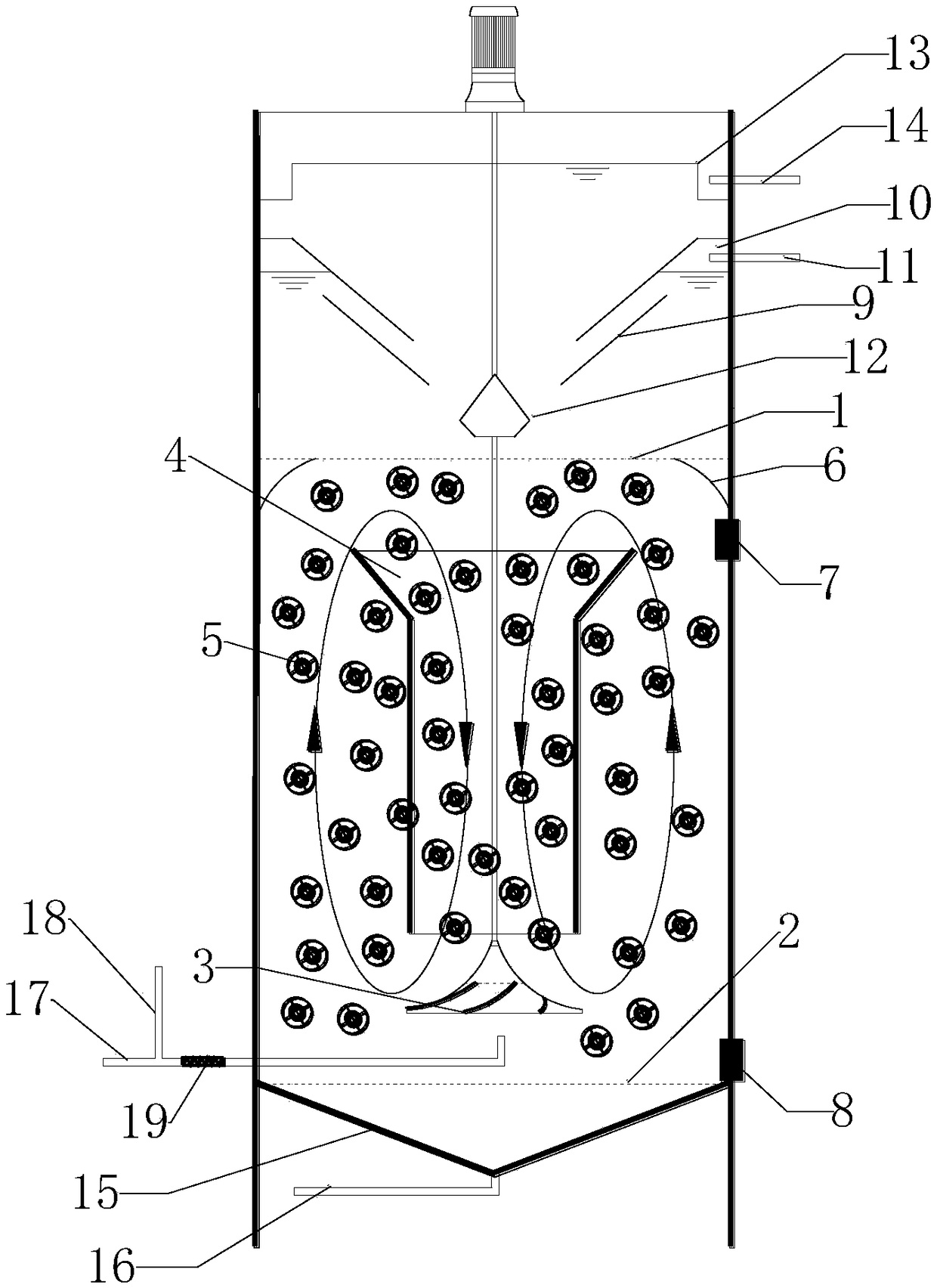

[0020] Such as figure 1 As shown, a wastewater denitrification denitrification reactor includes a three-phase separation zone, a reaction zone and a sludge discharge zone from top to bottom, the reaction zone and the three-phase separation zone are separated by the first mesh partition 1, and the reaction zone And the mud discharge area is separated by the second mesh partition 2.

[0021] A water inlet system is provided at the bottom of the reaction zone, a hyperboloid agitator 3 is installed in the center of the reaction zone, and a circular guide tube 4 is arranged above the impeller of the hyperboloid agitator 3, and the central axis of the guide tube 4 is aligned with the shaft 3 of the hyperboloid agitator Coincidentally, suspending filler 5 is added inside the reaction zone, and the first mesh partition 1 above the reaction zone is provided with a circle of diversion walls 6 along the pool wall. The suspended filler 5 realizes circulating fluidization under the synerg...

Embodiment 2

[0030] A waste water denitrification and denitrification reactor, with the production waste water of a polysilicon enterprise as the treatment object, carried out the pilot test of denitrification and denitrification. The filling rate of the suspended filler in the reactor is 50%, and the reactor device runs continuously for 24 hours, and industrial methanol is added as a carbon source. The pilot experiment was carried out continuously for 3 months, and some experimental data are shown in Table 1.

[0031] Table 1 Pilot test data of wastewater denitrification and denitrification

[0032] serial number

[0033] During the pilot test, the reaction device operated stably and basically had no failures. The experimental data shows that the influent TN is about 500 mg / L, which is reduced to less than 10 mg / L after treatment, and the removal rate reaches more than 98%, which meets the requirements of the discharge standard. After calculation, the total nitrogen removal vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com