Monolithic and system-level circuit integrated package structure of terahertz microstrip probe without jumper

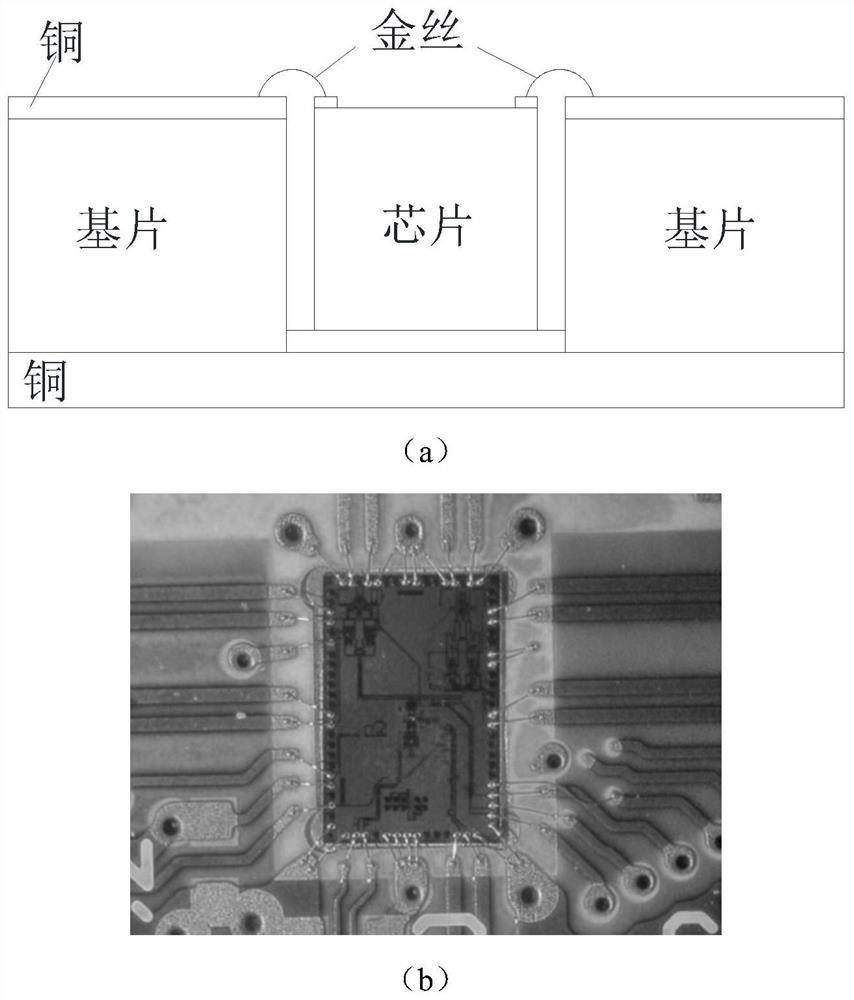

A technology of microstrip probe and packaging structure, which is applied in the direction of circuits, connecting devices, electrical components, etc., can solve the problems of inability to guarantee repeatability and consistency, high transmission loss, etc., to save chip thinning process and reduce loss , to eliminate the effect of large discontinuities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below with reference to the accompanying drawings.

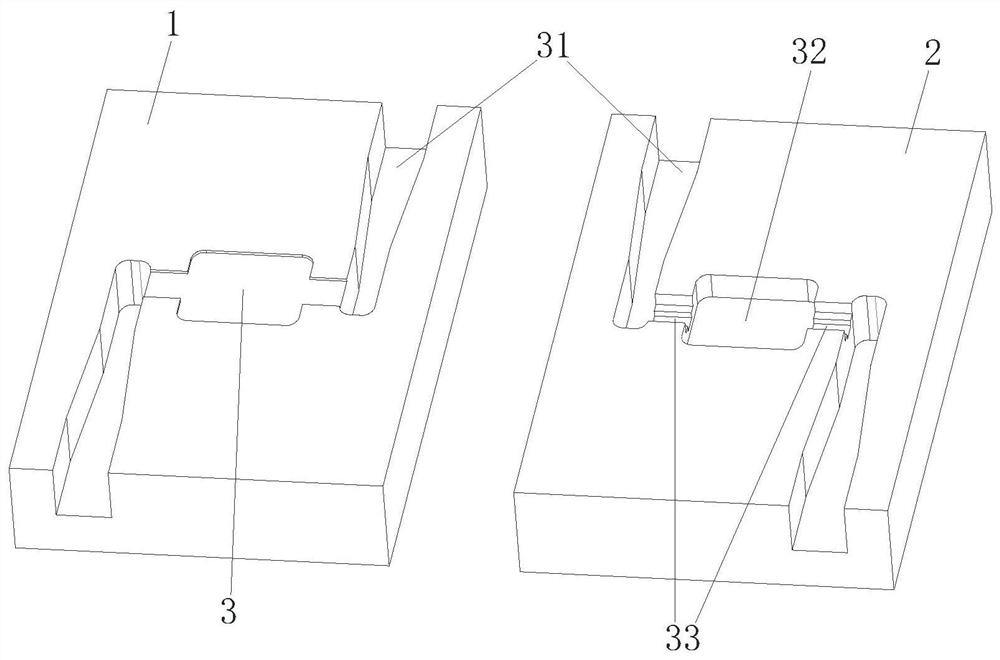

[0038] like figure 2 and image 3 As shown in the figure, the terahertz microstrip probe monolithic and system-level circuit interconnection integrated package in this embodiment includes a lower cavity 1, an upper cavity 2, a shielding cavity 3 formed between the upper and lower cavities, and The microstrip probe is interconnected and packaged in an integrated structure 4. The upper cavity 2 is assembled on the lower cavity 1 to form a rectangular waveguide cavity 31, a microstrip circuit shielding cavity 32 and a monolithic circuit shielding cavity 33.

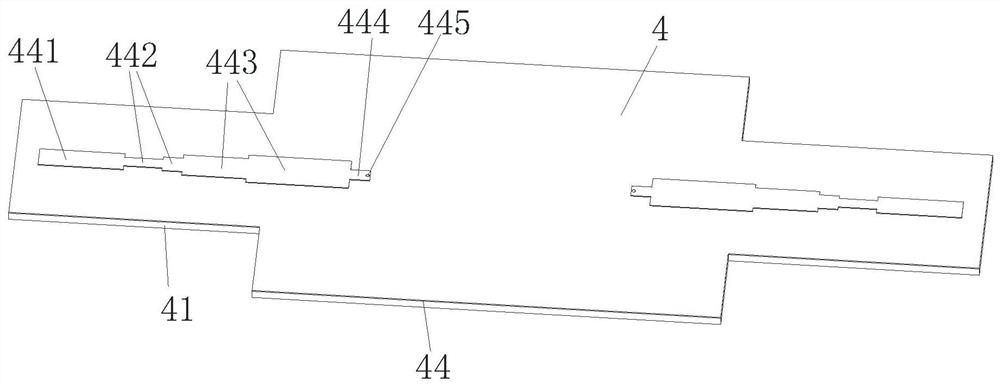

[0039] like image 3 , Figure 4 and Figure 5As shown, the microstrip probe interconnection package integrated structure 4 in this embodiment includes a microstrip probe 441, a probe impeda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com