Terahertz jump-free coplanar waveguide monolithic and system-level circuit low insertion loss packaging structure

A technology of coplanar waveguide and packaging structure, applied in waveguides, circuits, waveguide-type devices, etc., can solve the problem of inability to use terahertz monolithic and system-level circuit packaging structures on a large scale, easy fracture of quartz substrates, and complex processing technology. problem, to achieve the effect of eliminating chip thinning process, eliminating metal stripping, and low transmission insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

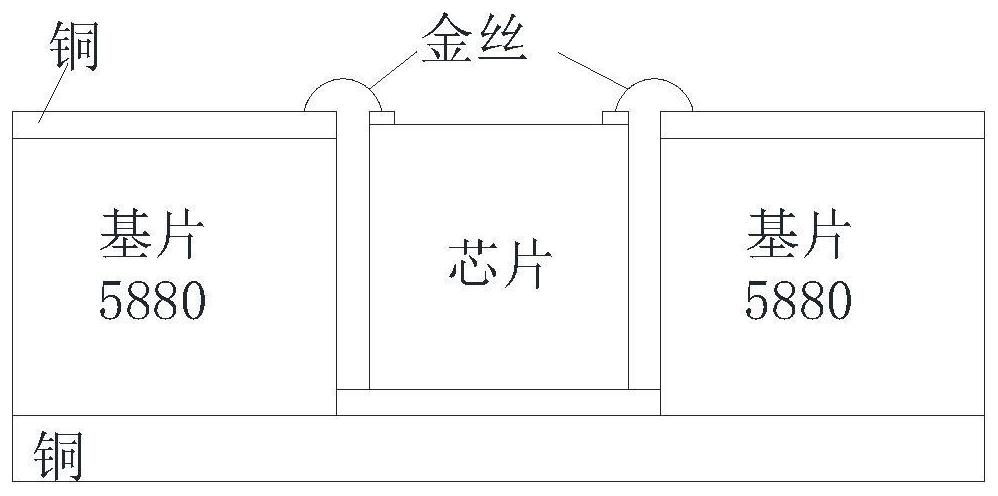

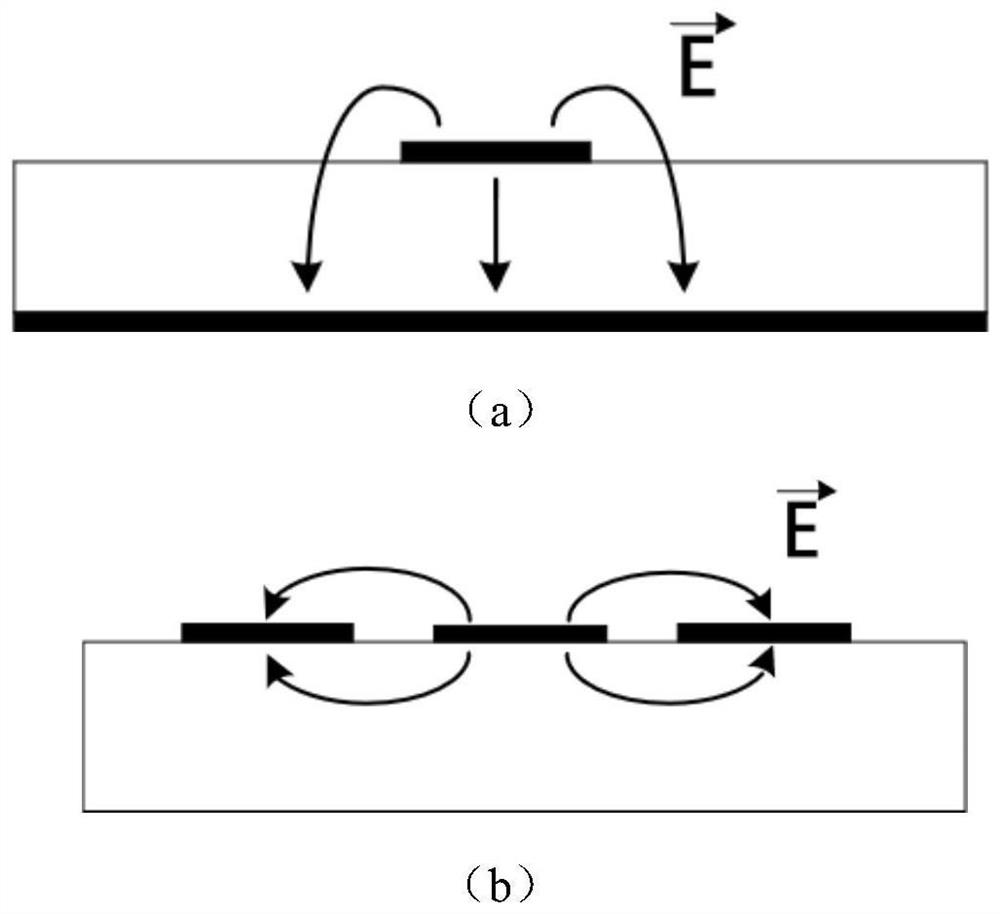

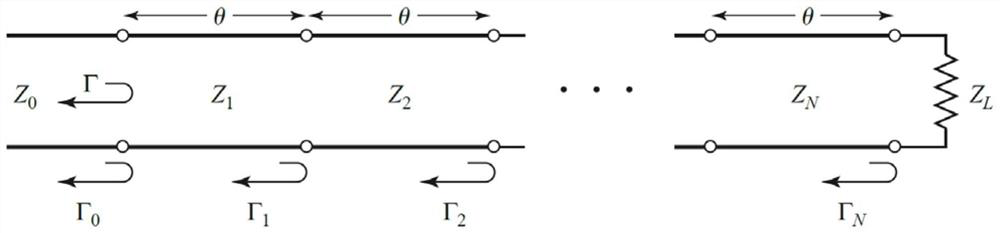

[0041] The coplanar waveguide transmission line uses metal atom sputtering technology to make high-precision metal patterns on the Pi dielectric layer. The center is the signal transmission line, and the metal ground planes are symmetrically distributed on both sides. The plastic sealing layer and the Pi dielectric layer constitute a double-layer composite dielectric substrate, in which the thickness of the plastic sealing layer is 150-200um (because the thickness of the plastic sealing layer is greater than 150um, it is easy to process, if it is consistent with the thickness of the terahertz chip, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com