Cooling method of automatic cooling system of photovoltaic cell panel

A photovoltaic panel and automatic cooling technology, applied in photovoltaic power generation, support structure of photovoltaic modules, photovoltaic modules, etc., can solve problems such as photovoltaic panels affecting life, achieve the effects of improving service life, receiving light well, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

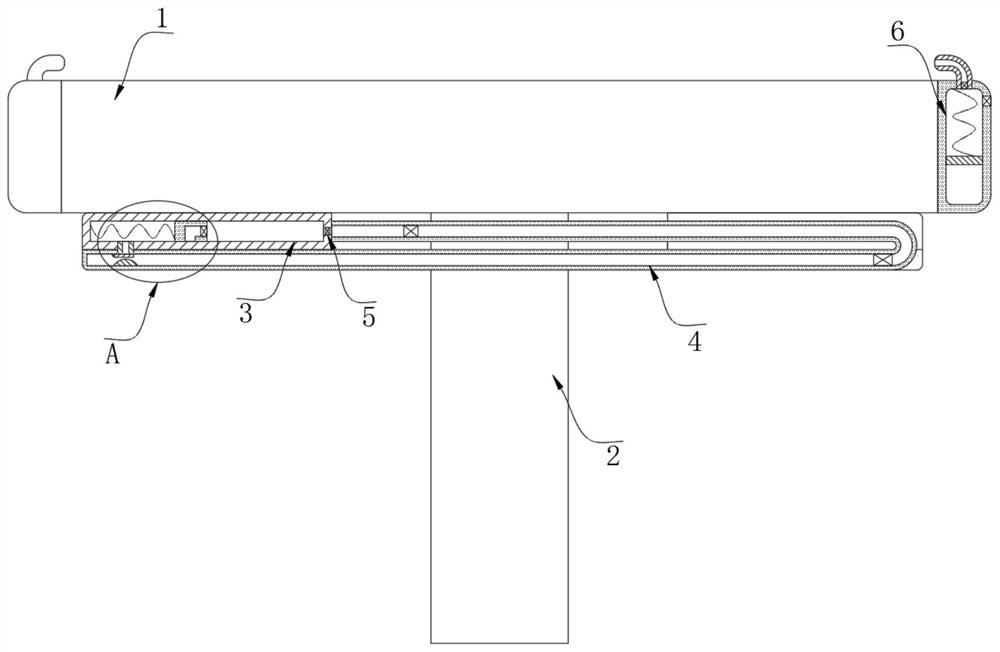

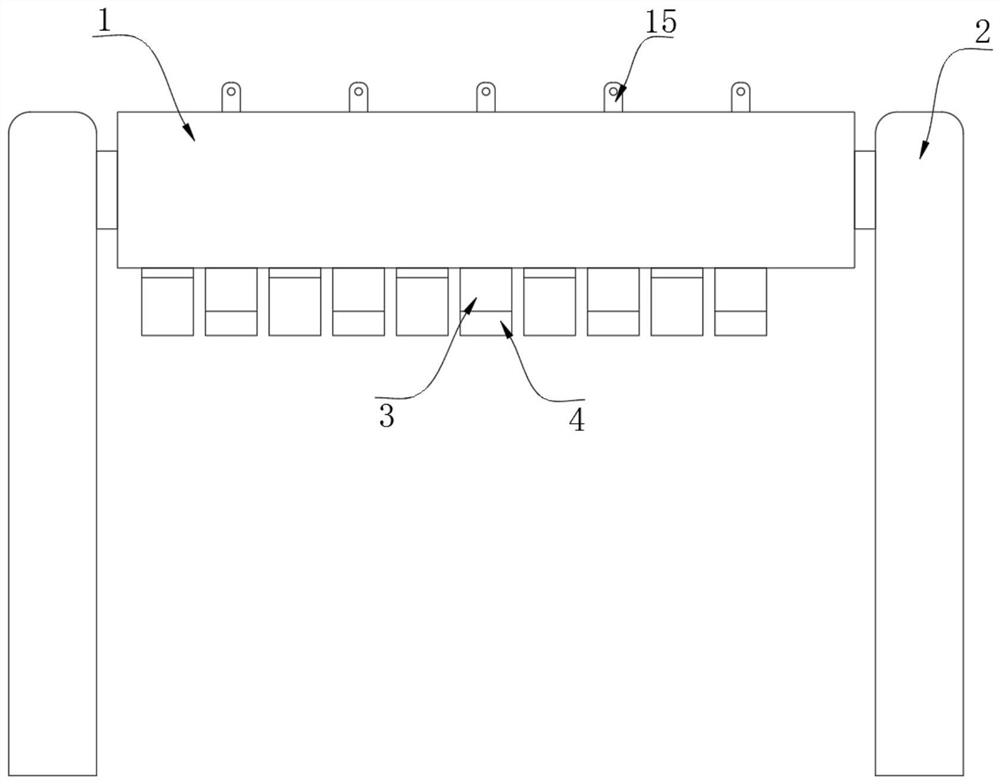

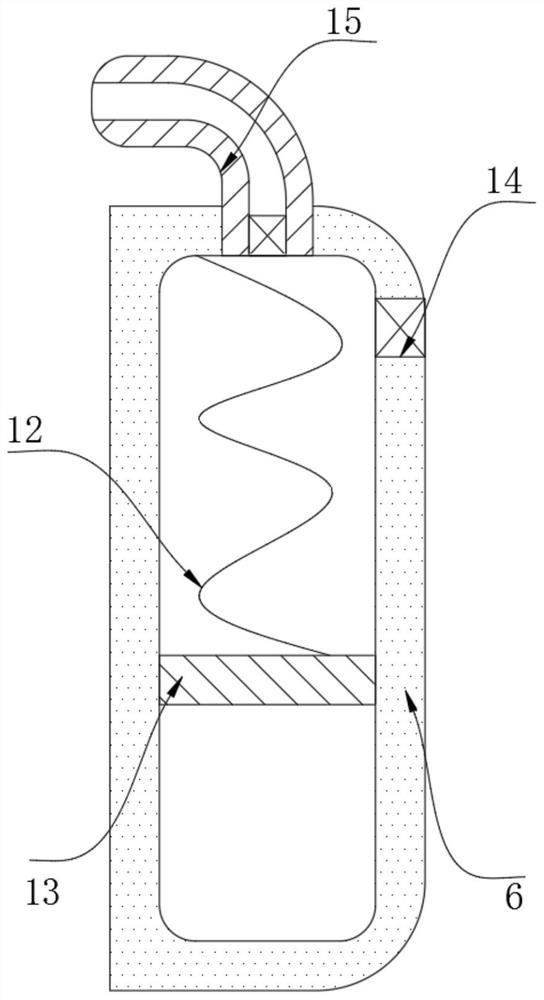

[0025] refer to Figure 1-4 , a cooling method for an automatic cooling system for photovoltaic panels, mainly comprising the following operating steps:

[0026] S1. Panel installation: fix the bracket 2 stably, ensure that the photovoltaic panel 1 is in a horizontal state in the initial state, check the state of the evaporating liquid inside the heat-absorbing tube 3, and ensure effective heat absorption and gasification;

[0027] S2. Heat absorption imbalance: When the light irradiates the photovoltaic panel 1 from one side, the evaporating liquid will absorb heat and vaporize, so as to cool down the photovoltaic panel 1, so as to avoid the high temperature of the photovoltaic panel 1 from affecting the life, while the light is biased to the side The evaporation efficiency of the evaporating liquid is significantly higher, which causes the balance block 8 on this side to move a greater distance by the air pressure, causing the two ends of the photovoltaic panel 1 to be unbal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com