Online flexible finishing method for spherical micro-grinding tool based on electromagnetic rheological effect

A spherical, electromagnetic technology, applied in the direction of machine tools, grinding machines, manufacturing tools, etc. suitable for grinding the edge of the workpiece, it can solve the problems of fast wear of abrasive tools, improve the quality of the processed surface, increase the contact area, improve the processing efficiency and processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-5 Specific embodiments of the present invention are described in detail.

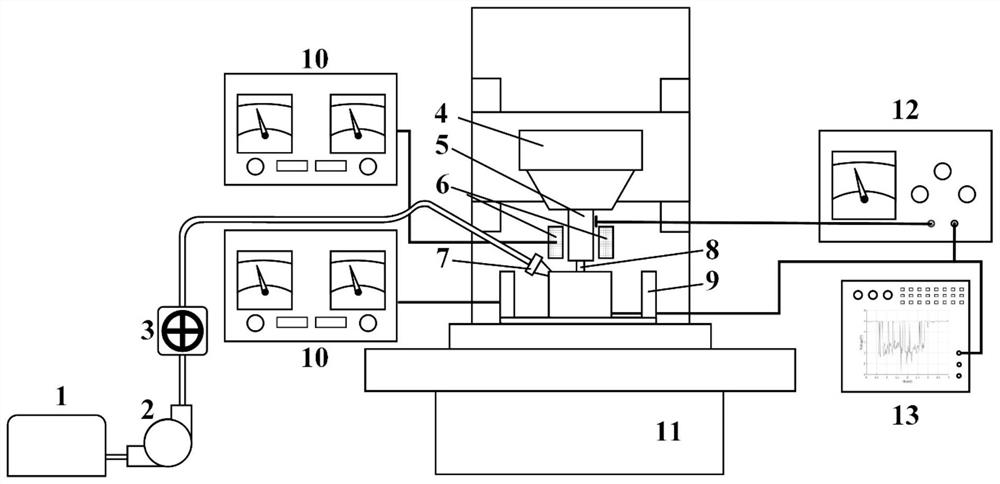

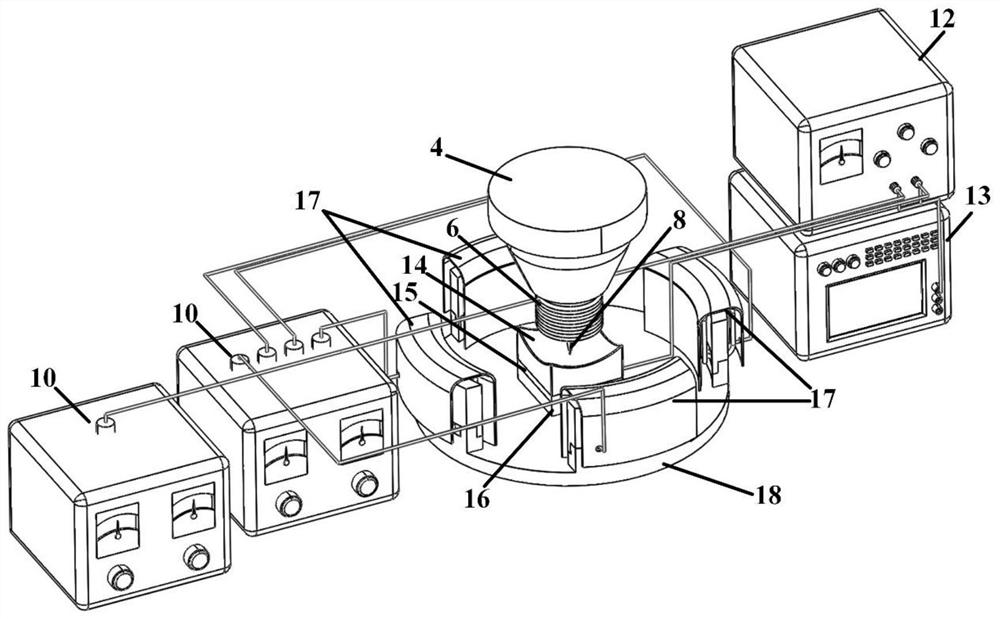

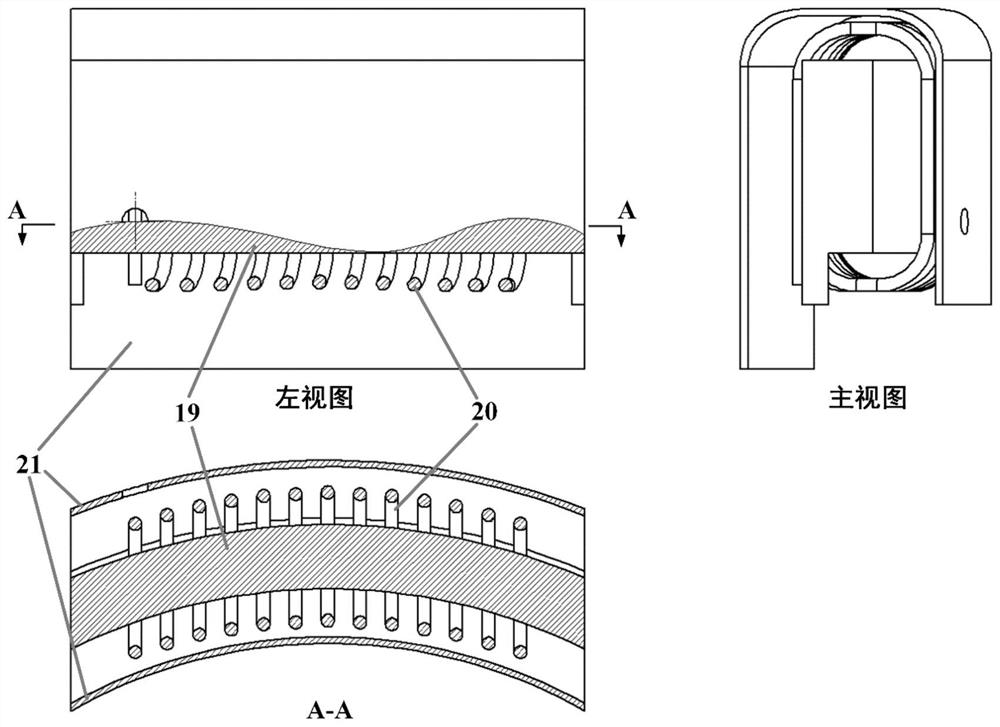

[0036] Such as Figure 1-3 As shown, this embodiment provides a nanofluid electromagnetic rheological grinding fluid and a spherical micro-grinding online flexible dressing device, including a grinding fluid reservoir 1, a water pump 2, a flow control valve 3, a spindle coil 6, and a nozzle 7 , a horizontal magnetic field auxiliary device 9, a frequency conversion control unit 10, a power supply 12, an oscilloscope 13, and an electrode 16, wherein: the grinding fluid reservoir 1 is connected with the water pump 2, the flow control valve 3, and the nozzle 7 sequentially through pipelines, and the liquid flow and The flow rate can be controlled and adjusted by the flow control valve 3 , and the electromagnetic rheological grinding fluid 22 is output to the area between the spherical micro grinding tool 8 and the micro curved surface part 14 through the nozzle 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com