A kind of high binding force electroplating equipment and its application method

An electroplating equipment and bonding force technology, applied in the field of high-bonding force electroplating equipment, can solve the problems of economic loss, rough coating, insufficient coating bonding force, etc., and achieve the effects of improving bonding force, preventing backflow, and improving filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

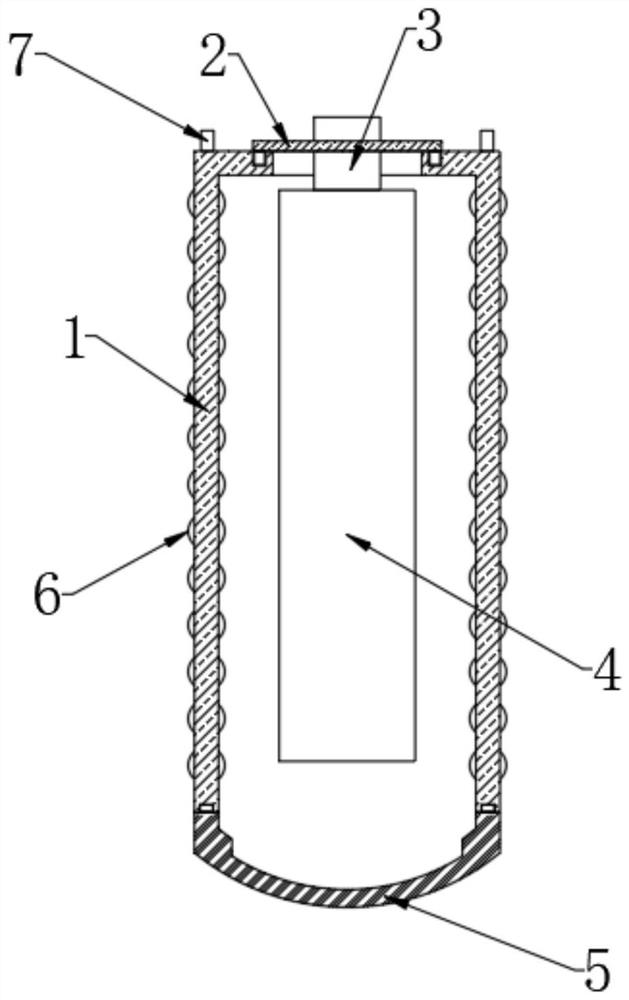

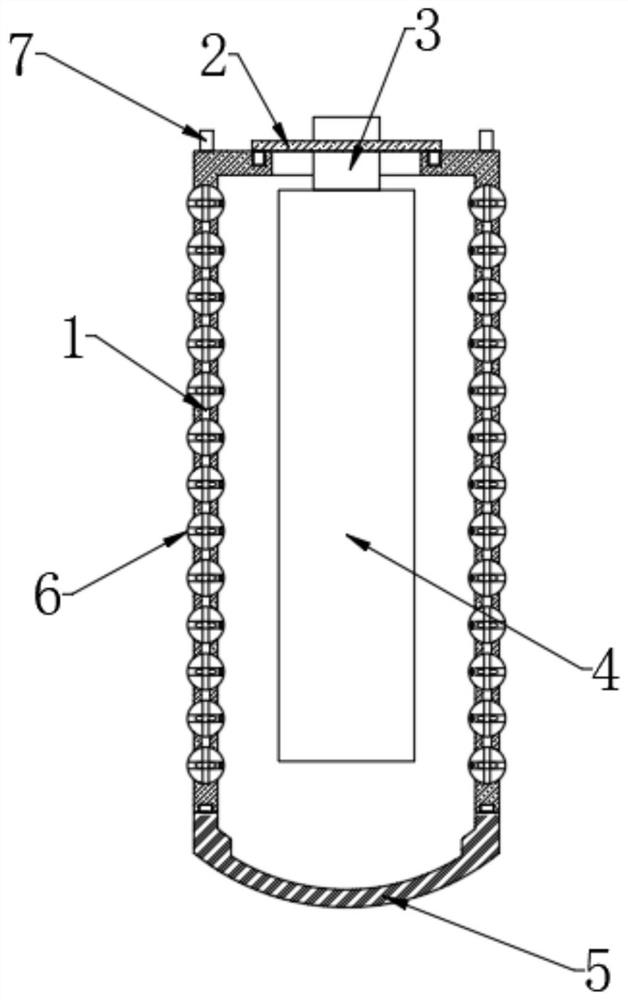

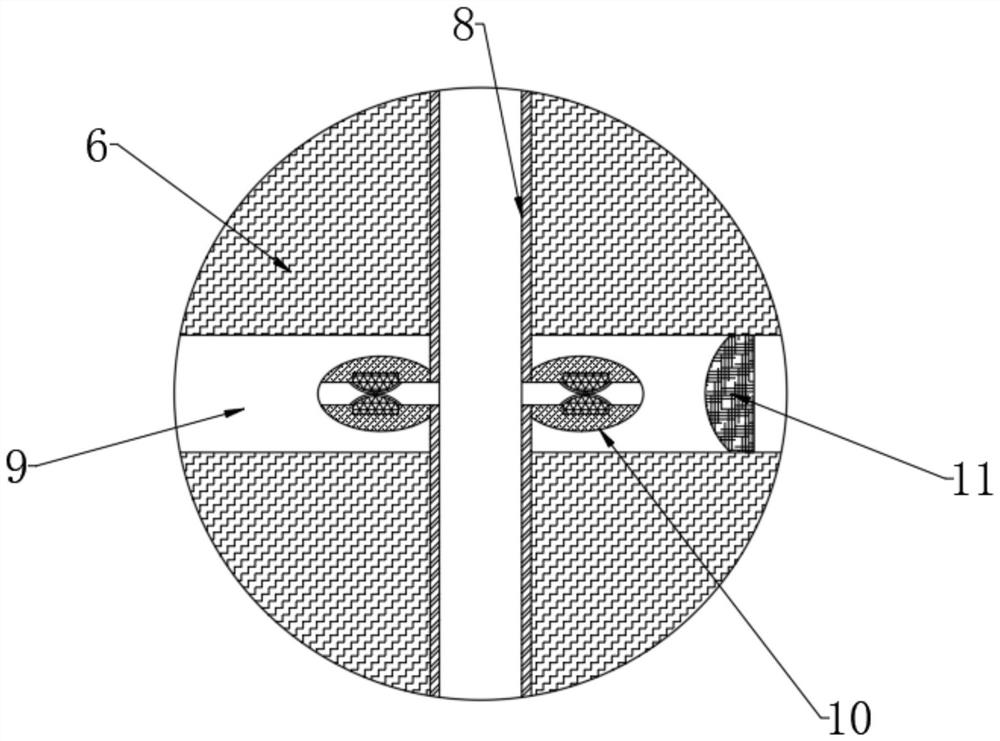

[0046] see Figure 1-7 , a high-binding force electroplating device, including a choke case 1 and an anode 4, see Figure 1-2 , the upper end of the choke case 1 is provided with an opening, and the opening is connected with a sealing plate 2, the sealing plate 2 is fixedly connected with a clamp 3, and the anode 4 is clamped at the lower end of the clamp 3, and the lower end of the choke case 1 is connected with a connector. The bottom shell 5, the sealing plate 2, the bottom shell 5 and the choke shell 1 are all connected by magnetic adsorption to facilitate installation and disassembly, and a gasket is provided at the joint to prevent impurities from entering through the gap Into the external electroplating solution, the side wall of the choke case 1 is fixedly embedded with a plurality of filter balls 6, and the inner wall of the choke case 1 is fixedly embedded with a vent pipe 8 passing through a plurality of filter balls 6, and the upper end side of the choke case 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com