Natural gas hydrate reservoir true triaxial hydraulic fracturing simulation test device and method

A hydraulic fracturing and simulation test technology, which is used in the application of stable tension/pressure to test the strength of materials, measuring devices, soil material testing, etc. It can solve the complex internal structure, the sealing problem is not effectively solved, and it is difficult to monitor the fracturing fluid. flow and other problems, to achieve the effect of simple test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

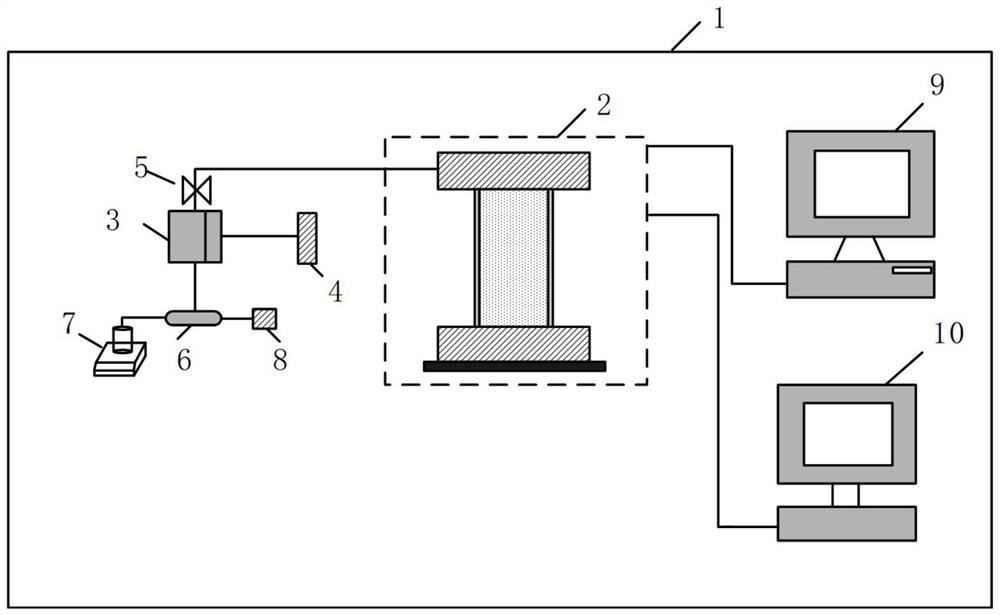

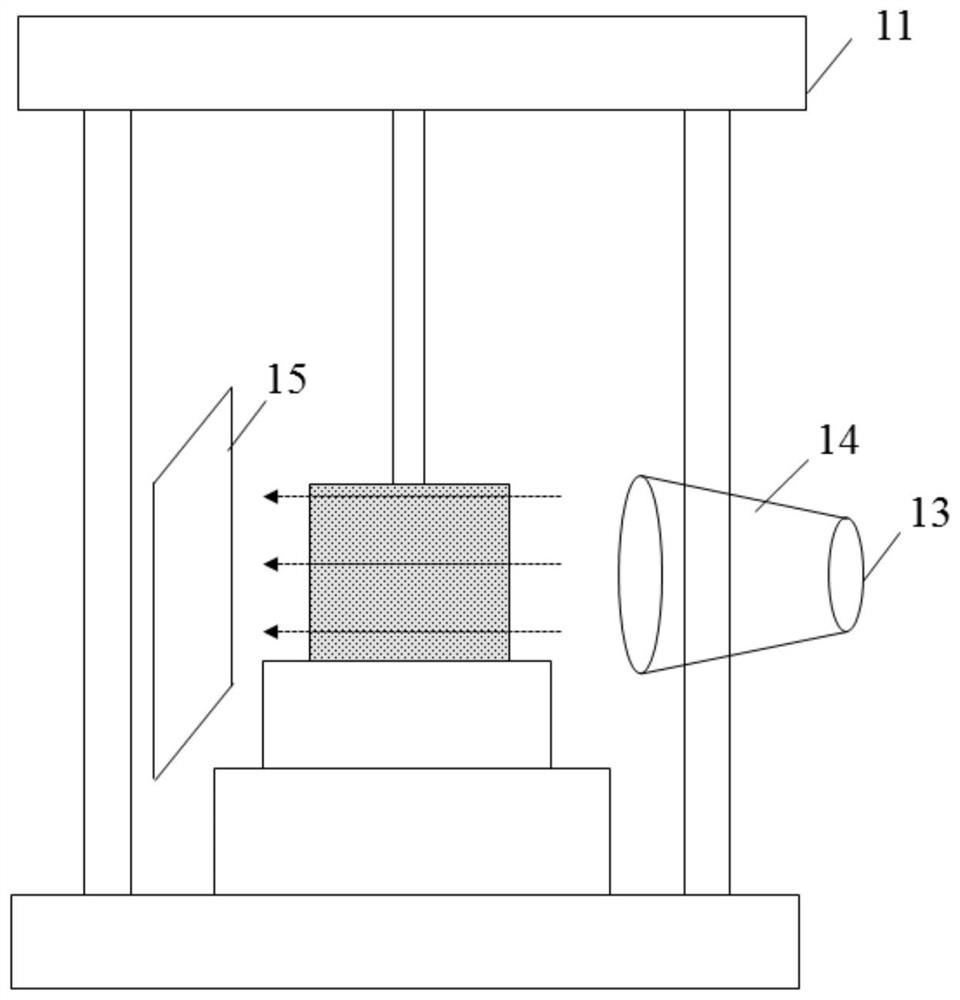

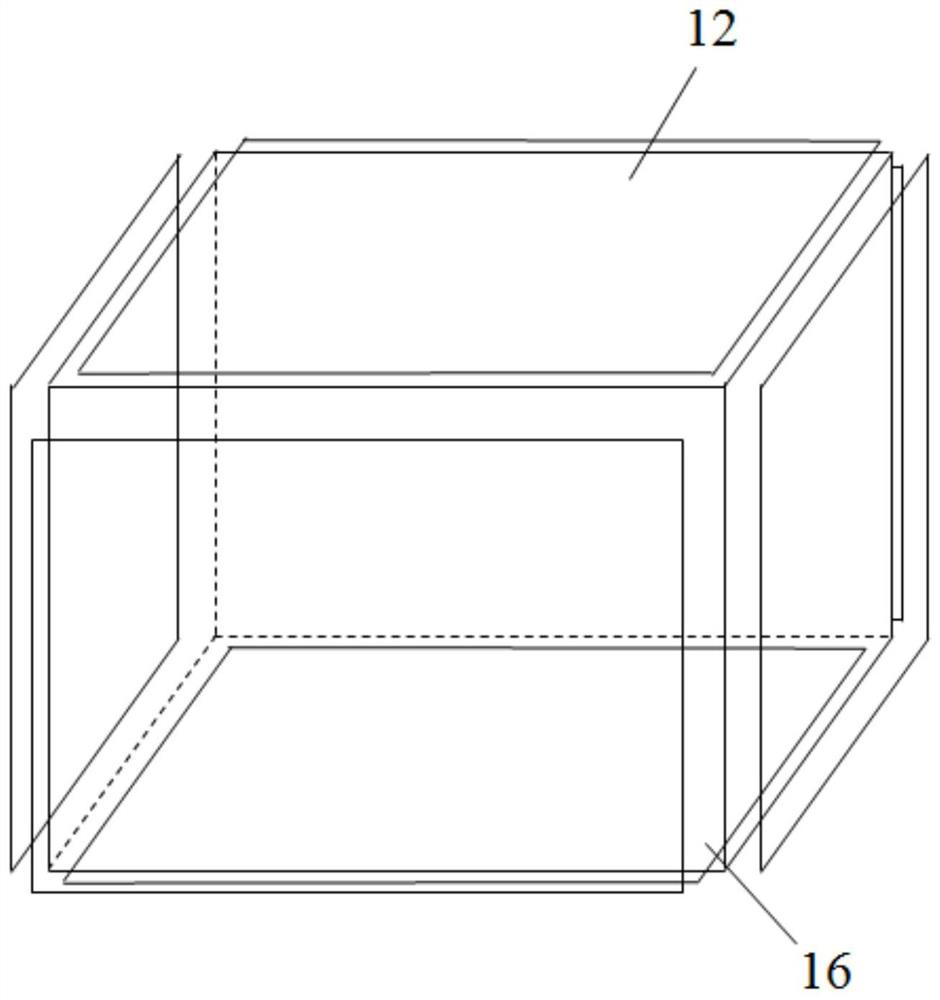

[0037] combine Figure 1 to Figure 9 As shown, the specific implementation of a true triaxial hydraulic fracturing simulation test device and method for a natural gas hydrate reservoir provided by the present invention will be described.

[0038]A true triaxial hydraulic fracturing simulation test device for natural gas hydrate reservoirs, including a temperature control system, a true triaxial hydraulic fracturing system, a gas-liquid acquisition system, a neutron camera monitoring system, and a fracturing control and data acquisition system. Through this device, hydraulic fracturing simulation tests of hydrate-containing sediments under true three-dimensional stress state can be carried out, the hydraulic fracturing characteristics of natural gas hydrate reservoirs under true three-dimensional stress state can be studied, and the true three-dimensional stress state can be determined. The role of hydraulic fracturing in natural gas hydrate recovery.

[0039] Among them, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com