Method for determining dosage of fluxing agent for measuring sulfur element in sample by infrared absorption method

A determination method and technology of flux, which are applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of high measurement cost and doubling bad effect of flux, so as to improve the accuracy and precision and reduce the measurement cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Experimental design scheme: multiple groups of samples of uniform quality are provided. Theoretically speaking, the sulfur content in each group of samples is the same, and different masses of co-solvents are added to each group of samples. The carbon-sulfur analyzer is used to pass through In the process of measuring sulfur by infrared absorption method, the measured value of sulfur is analyzed separately, and it can be seen that with the continuous increase of flux quality, the measured value of sulfur continues to increase.

[0045] For example, to measure the standard material nickel-based superalloy GBW 01641, the standard value of sulfur is S=0.0046%, and the fixed mass is 0.500 grams. With the continuous increase of the amount of multi-element flux, the measured values of sulfur were analyzed separately by using a carbon-sulfur analyzer, as shown in Table 2.

[0046] Table 2 Flux quality-sulfur measurement value-sulfur growth rate table for nickel-based superal...

Embodiment 2

[0073] Measure single crystal superalloy DD6 and quantitatively judge the appropriate dosage of tungsten-tin-iron flux.

[0074] (1) Fixedly weigh the quality of single crystal superalloy DD6, 0.350 grams, and place it in a bottomed crucible;

[0075] (2) Take by weighing the tungsten-tin-iron flux quality as table 4, add in the single crystal superalloy DD6 of 0.350 gram;

[0076] (3) The carbon and sulfur analyzer uses the enhanced sensitivity mode to measure the sulfur measurement value, which is listed in Table 4;

[0077] (4) Taking flux quality 0.10 g as an interval, calculate the sulfur growth rate at each point, and list it in Table 4;

[0078] Table 4 Flux quality-measured value of sulfur-sulfur growth rate table for single crystal superalloy DD6

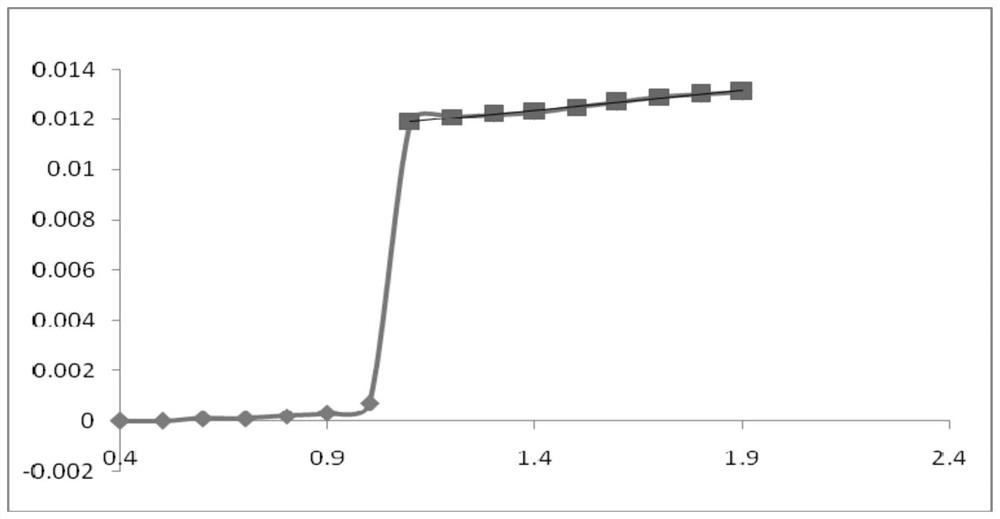

[0079]

[0080] In table 4, the maximum point of sulfur growth rate (0.90 grams) is the maximum release of sulfur in the sample, the first point after the maximum point, that is, 1.00 grams after adding 0.10 grams of f...

Embodiment 3

[0083] Quantitative judgment of silicon steel and tungsten-tin flux suitable dosage.

[0084] (1) Fixedly weigh the quality of silicon steel, 0.250 grams;

[0085] (2) Take by weighing the tungsten-tin flux quality of table 5, add in the silicon steel of 0.250 gram;

[0086] (3) Use the carbon-sulfur analyzer to record the sulfur measurement value, which is listed in Table 5;

[0087] (4) Taking flux quality 0.10 g as an interval, calculate the sulfur growth rate at each point, and list it in Table 5;

[0088] Table 5 Silicon steel flux quality-measured value of sulfur-sulfur growth rate table

[0089]

[0090]

[0091] In table 5, the maximum point of sulfur growth rate (1.20 grams) is the maximum release of sulfur in the sample, the first point after the maximum point, that is, 1.30 grams after adding 0.10 grams of flux, to ensure that the sulfur in the sample is fully released come out. At the same time, add 0.10 grams of flux, even if the increase of sulfur relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com