Hot continuous rolling strip steel width prediction method based on cooperation of principal component analysis and random forest

A principal component analysis and random forest technology, used in computer parts, instruments, characters and pattern recognition, etc., can solve the problems of falling into local minima, slow convergence speed, nonlinearity, etc., to improve enterprise efficiency and improve production. efficiency, reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

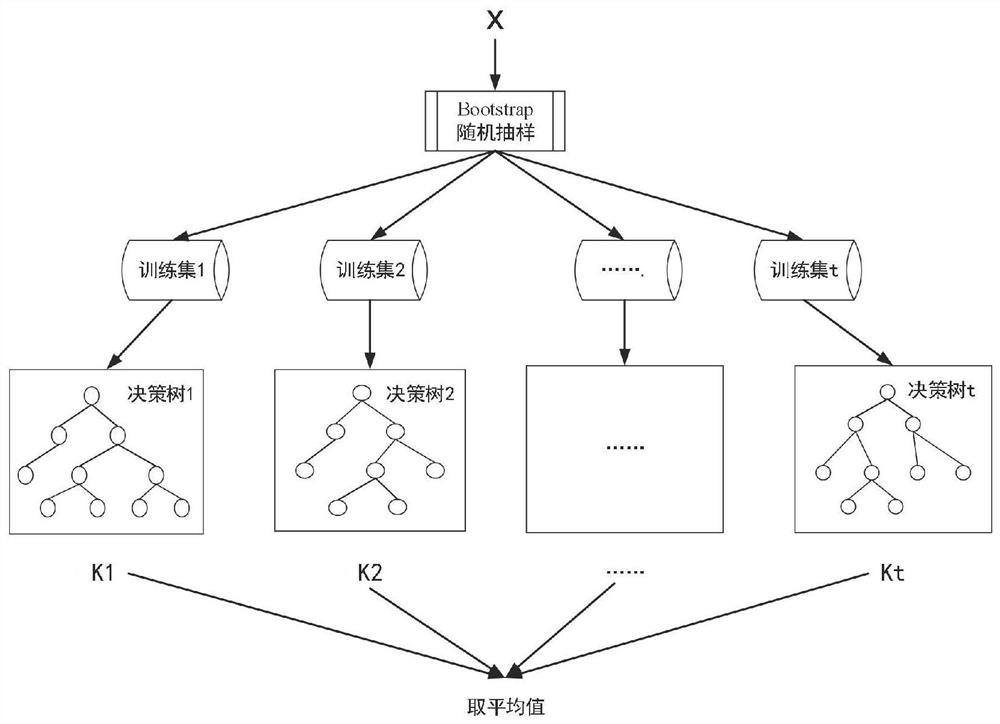

[0051] In this embodiment, taking the hot rolling mill production line as an example, the hot strip width prediction method of principal component analysis collaborative random forest (i.e. PCA-RF) of the present invention is used to change the strip steel type, specification and roll change. The first steel export width is predicted.

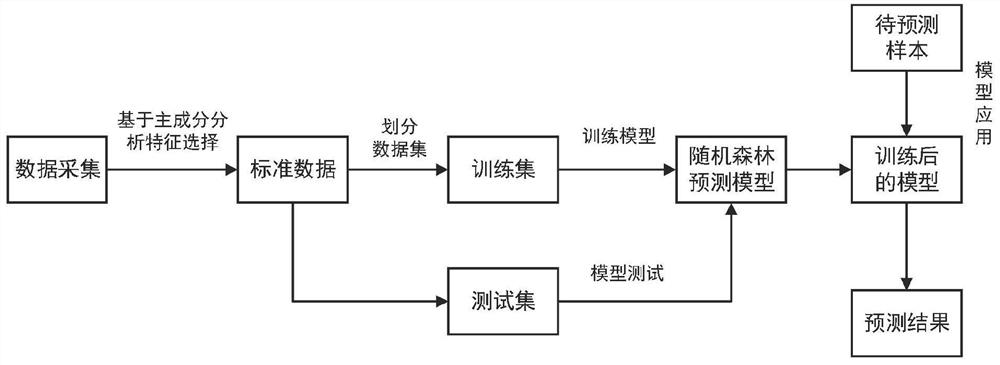

[0052] In this embodiment, a method for predicting the width of hot strip steel strips in conjunction with principal component analysis and random forests, such as figure 1 shown, including the following steps:

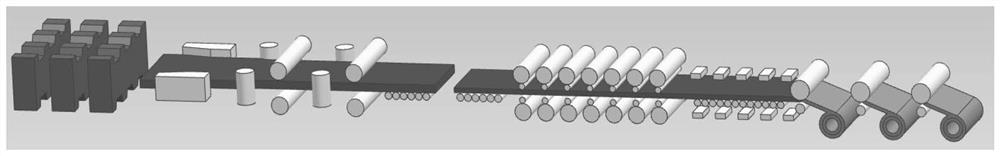

[0053] Step 1. Determine the equipment layout form of the hot continuous rolling production line, and determine the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com