Drying method of pitaya slices

A drying method, technology of dragon fruit slices, applied in food drying, preservation of fruits/vegetables through dehydration, food science, etc., can solve the problems of unfavorable active substance retention, dried fruit shape, poor taste, browning reaction, etc., to achieve Shorten drying time, solve quality deterioration, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

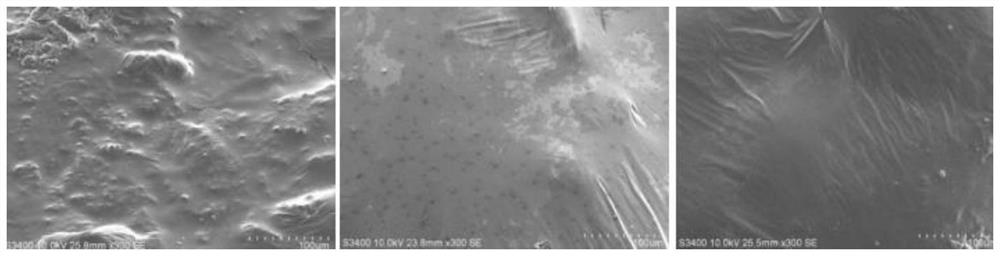

Image

Examples

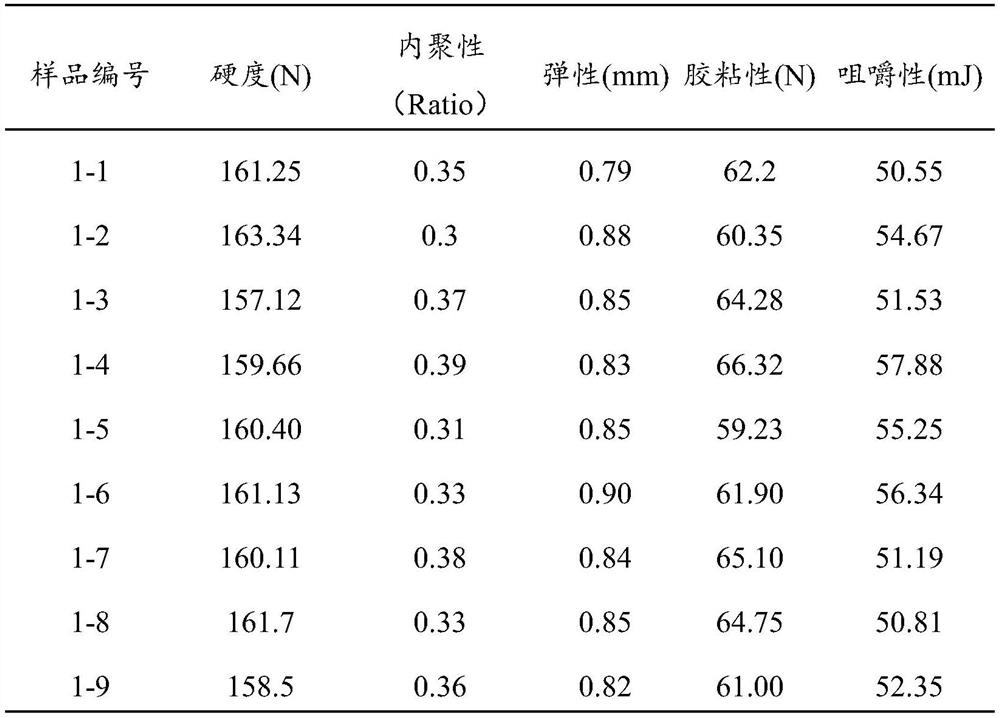

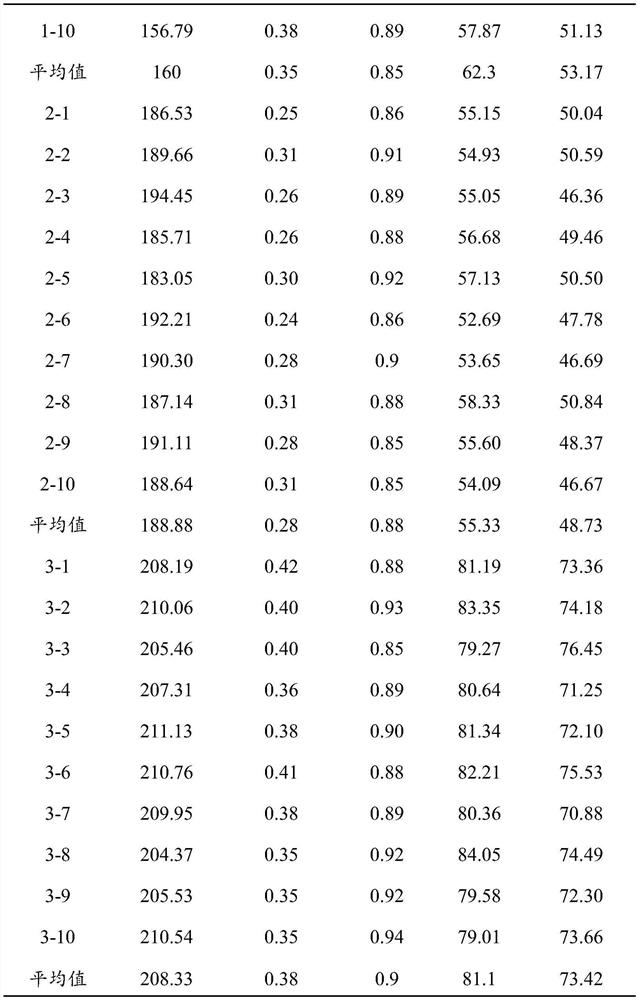

Embodiment 1

[0031] Choose half-ripe dragon fruit, peel it, cut it into thin slices of about 6mm, weigh 1.3kg, put it into a baking tray, ensure that there is no overlap, and carry out microwave drying: first use 2kw microwave power, microwave drying for 5min; then use 1kw Microwave power, microwave drying for 10 minutes; then microwave drying with 0.5kw microwave power for 15 minutes.

[0032] The fruit slices obtained by microwave drying were transferred to a heat pump drying oven, dried with hot air at a constant temperature of 55°C for 5 hours, and then dried at a constant temperature of 65°C for 3 hours, and then the fruit slices were taken out and put into sealed bags.

[0033] After three microwave drying treatments, the water content of the dragon fruit slices was reduced by 40%; after two hot air drying treatments, the final water content of the dragon fruit slices was 8wt.%.

Embodiment 2

[0035] Choose half-ripe dragon fruit, peel it, cut it into thin slices of about 7mm, weigh 1.4kg, put it in a baking tray to ensure that there is no overlap, and carry out microwave drying: first use 2kw microwave power, microwave drying for 10min; then use 1kw Microwave power, microwave drying for 10 minutes; then microwave drying with 0.5kw microwave power for 10 minutes.

[0036] The fruit slices obtained by microwave drying were transferred to a heat pump drying oven, dried with hot air at a constant temperature of 55°C for 5 hours, and then dried at a constant temperature of 65°C for 3 hours, and then the fruit slices were taken out and put into sealed bags.

[0037] After three microwave drying treatments, the water content of the dragon fruit slices was reduced by 45%; after two hot air drying treatments, the final water content of the dragon fruit slices was 7wt.%.

Embodiment 3

[0039] Choose half-ripe dragon fruit, peel it, cut it into thin slices of about 7mm, weigh 2.0kg, put it in a baking tray to ensure that there is no overlap, and carry out microwave drying: first use 2kw microwave power, microwave drying for 10min; then use 1kw Microwave power, microwave drying for 15 minutes; then microwave drying with 0.5kw microwave power for 20 minutes.

[0040] The fruit slices obtained by microwave drying were transferred to a heat pump drying oven, dried with hot air at a constant temperature of 55°C for 5 hours, and then dried at a constant temperature of 65°C for 4 hours, and then the fruit slices were taken out and put into sealed bags.

[0041] After three microwave drying treatments, the water content of pitaya slices decreased by 43%; after two hot air drying treatments, the final water content of dragon fruit slices was 7wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com