Method for processing cooked frozen swimming crabs

A processing method, swimming crab technology, applied in food freezing, meat/fish preservation, heating and preservation of meat/fish, etc., can solve problems such as high tripping rate, quality deterioration, etc., to reduce tripping rate, save cost, solve The effect of high drop rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

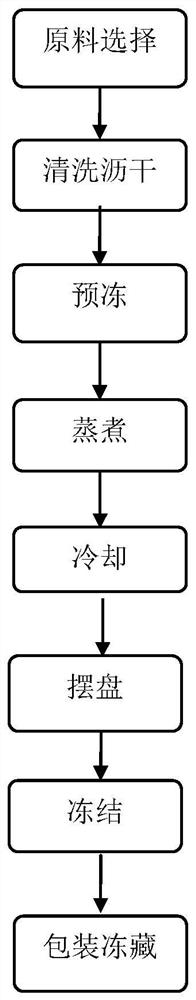

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a kind of processing method of boiled and frozen swimming crab, comprising the following steps:

[0036] (1) Raw material selection: choose swimming crabs with complete claws and no damage, each about 100-150g;

[0037] (2) Cleaning: Clean the portunus with flowing water and drain the surface moisture;

[0038] (3) Pre-freezing: place the cleaned and drained swimming crabs in a blast freezer, and pre-freeze them with blast at -28~-35°C for 5 minutes, so that the vitality of the swimming crabs will be reduced but not frozen, and the vitality and fresh state will be maintained;

[0039] (4) Steaming: take the pre-frozen swimming crabs out of the blast freezer, transfer them to a continuous cooking machine within 10 minutes and steam them for 8 minutes until the center temperature of swimming crabs is 70-75°C;

[0040] (5) Cooling: After the portunus is steamed, it is immediately cooled to below 30°C by spraying with 0-4°C cold water, and then coo...

Embodiment 2

[0045] This embodiment provides a kind of processing method of boiled and frozen swimming crab, comprising the following steps:

[0046] (1) Raw material selection: choose swimming crabs with complete claws and no damage, each about 300-350g;

[0047] (2) Cleaning: Clean the portunus with flowing water and drain the surface moisture;

[0048] (3) Pre-freezing: place the cleaned and drained swimming crabs in a blast freezer, and pre-freeze them with blast at -28 to -35°C for 10 minutes, so that the vitality of the swimming crabs will be reduced but not frozen, and the vitality and fresh state will be maintained;

[0049] (4) Steaming: take the pre-frozen swimming crabs out of the blast freezer, transfer them to a continuous steamer within 10 minutes and steam them for 10 minutes until the central temperature of the swimming crabs is 70-75°C;

[0050] (5) Cooling: After the portunus is steamed, it is immediately cooled to below 30°C by spraying with 0-4°C cold water, and then c...

Embodiment 3

[0055] This embodiment provides a kind of processing method of boiled and frozen swimming crab, comprising the following steps:

[0056] (1) Raw material selection: choose swimming crabs with complete claws and no damage, each about 450-500g;

[0057] (2) Cleaning: Clean the portunus with flowing water and drain the surface moisture;

[0058] (3) Pre-freezing: place the cleaned and drained swimming crabs in a blast freezer, and pre-freeze them with blast at -28 to -35°C for 15 minutes, so that the vitality of the swimming crabs will be reduced but not frozen, and the vitality and fresh state will be maintained;

[0059] (4) Steaming: Take the pre-frozen swimming crabs out of the blast freezer, transfer them to a continuous cooking machine within 10 minutes and steam them for 12 minutes until the center temperature of swimming crabs is 70-75°C;

[0060] (5) Cooling: After the portunus is steamed, immediately use 0-4°C cold water spray to cool to below 30°C, and then use circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com