Movable pressure swing adsorption oxygen production device

A technology of pressure swing adsorption and production equipment, which is applied in the directions of oxygen preparation, oxygen/ozone/oxide/hydroxide, transportation and packaging, etc. Blocking, reducing work efficiency and other problems, to achieve the effect of easy disassembly, ensuring stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

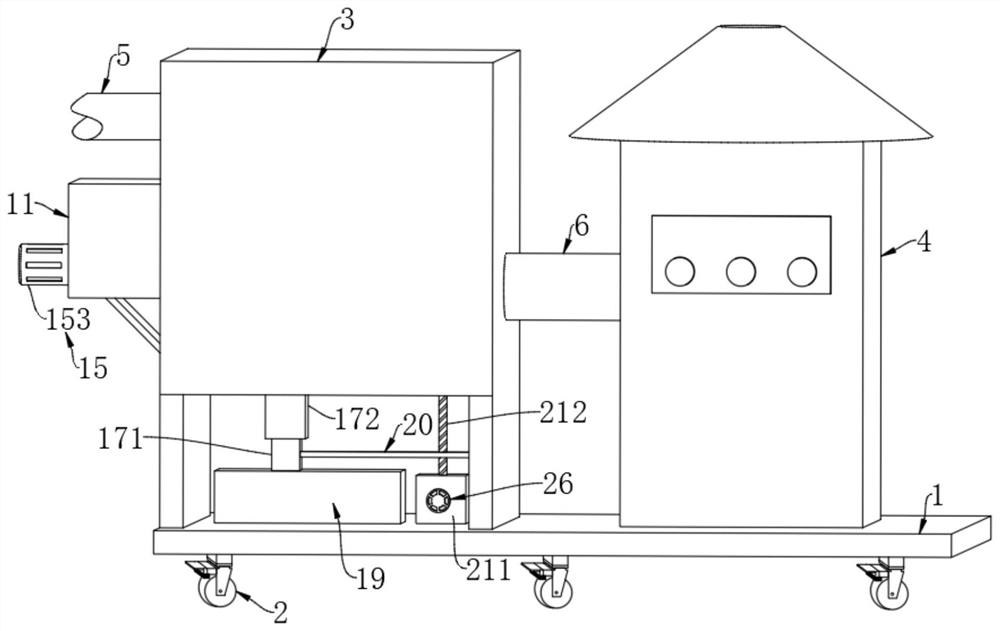

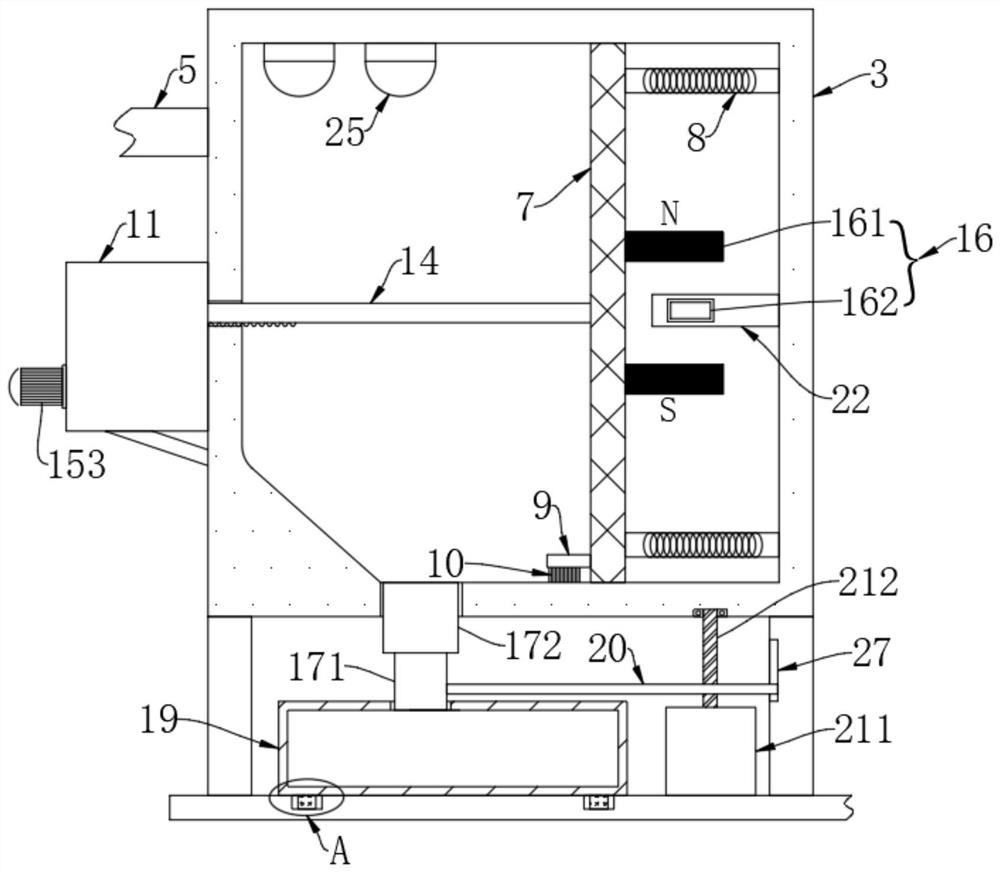

[0031] Such as Figure 1-6 As shown, a mobile pressure swing adsorption oxygen production device includes a support base 1, a plurality of universal wheels 2 are fixedly connected to the lower end of the support base 1, and the universal wheels 2 can be self-locking. It is convenient for the staff to move the whole device, avoiding the labor loss caused by manual lifting of the device, and the self-locking function of the universal wheel 2 can ensure the stability of the device placement.

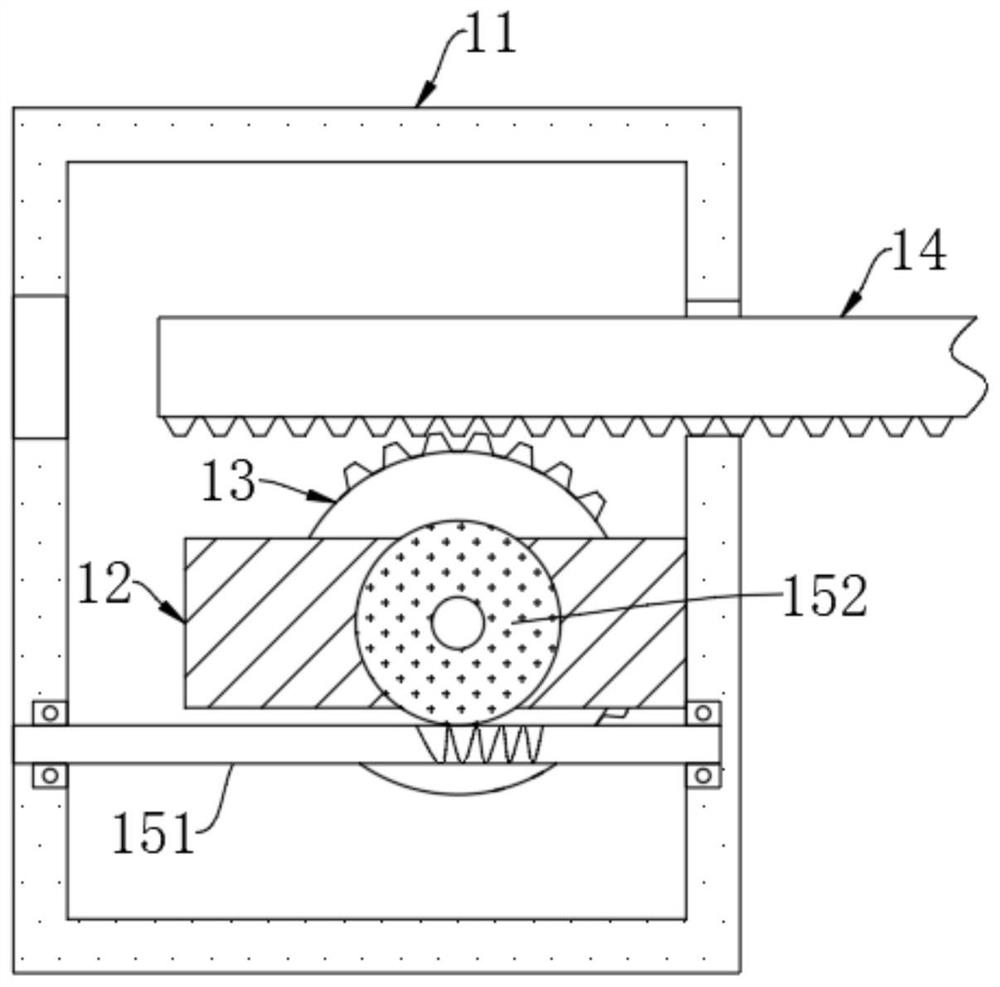

[0032] The support base 1 is fixedly connected with the filter box 3 and the main body 4 of the pressure swing adsorption oxygen generator. The filter box 3 is provided with a plurality of purple light lamps 25, and the purple light lamps 25 are electrically connected with the power generation mechanism 16. Through the set purple light lamps 25 , can cooperate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com