A kind of aroma sustained-release capsule and its preparation method

A slow-release capsule and aroma technology, which is applied to microcapsule preparations, microsphere preparation, vaporized substances, etc., can solve the problems of excessive aroma volatilization speed, pollution of human health, waste of resources and the environment, etc., to enhance the slow-release ability of aroma , The effect of prolonging the single use time and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

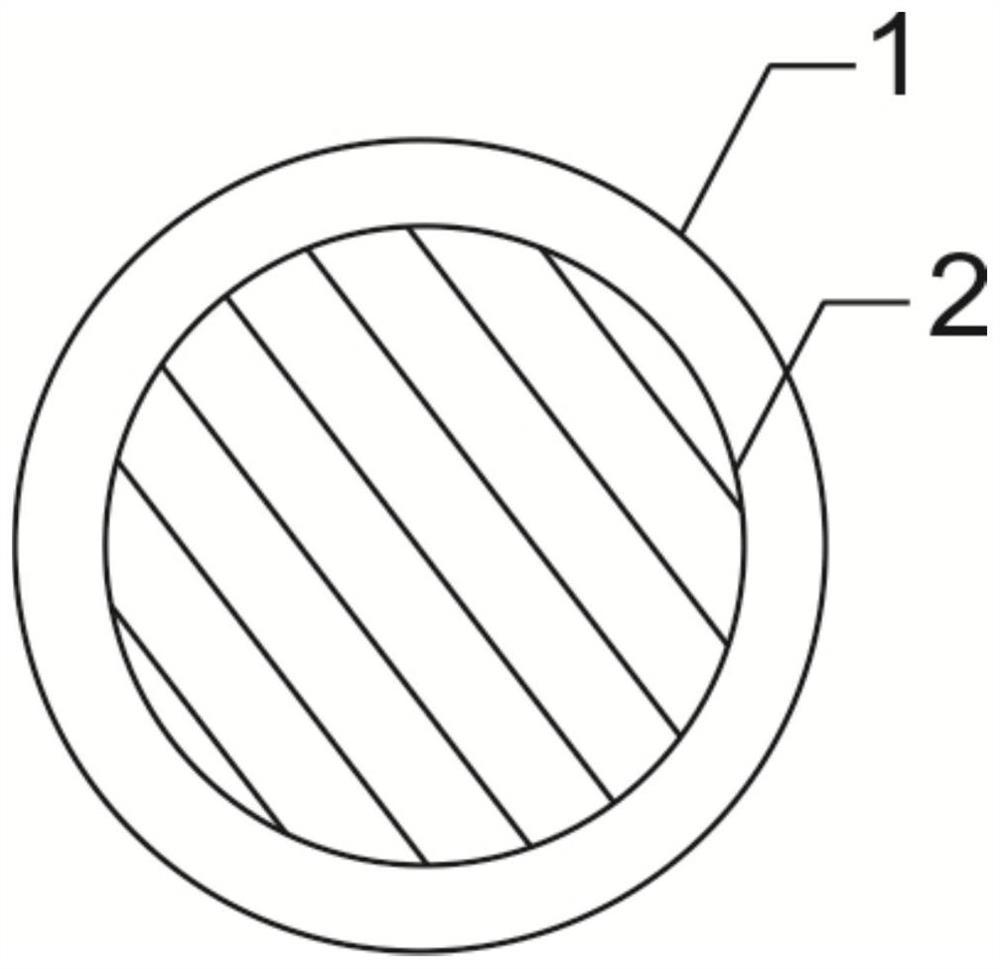

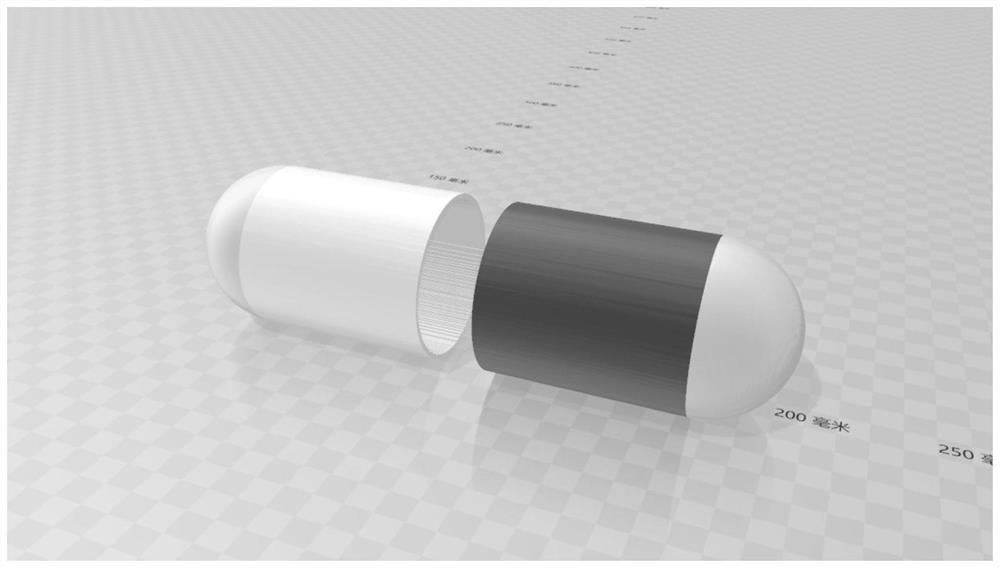

[0030] An aroma sustained-release capsule includes composite microspheres 2, the composite microspheres 2 include a plurality of microsphere units, and a matching capsule shell 1 is arranged outside the composite microspheres 2. The pore diameter of the composite microspheres 2 is 10 nm, and the length of the capsule shell 1 is 200 mm; the composite microspheres 2 are starch-β cyclodextrin composite microspheres, and the material of the capsule shell 1 is xanthan gum.

[0031] The preparation method of above-mentioned aroma sustained-release capsule, comprises the following steps:

[0032] (1) Mix β-cyclodextrin and pretreated starch in a mass ratio of 2:1, then add deionized water 6 times by mass of the pretreated starch, adjust the pH value to 10.2, and then add a cross-linking aid at 20KV / cm and Pulse electric field treatment is carried out under the condition of 200Hz, followed by centrifugation, washing and drying to obtain starch-β cyclodextrin; the cross-linking assista...

Embodiment 2

[0037] An aroma sustained-release capsule includes composite microspheres 2, the composite microspheres 2 include a plurality of microsphere units, and a matching capsule shell 1 is arranged outside the composite microspheres 2. The pore diameter of the composite microsphere 2 is 40 nm, and the length of the capsule shell 1 is 200 mm; the composite microsphere 2 is a starch-β cyclodextrin composite microsphere, and the material of the capsule shell 1 is xanthan gum.

[0038] The preparation method of above-mentioned aroma sustained-release capsule, comprises the following steps:

[0039](1) Mix β-cyclodextrin and pretreated starch at a mass ratio of 3:1, then add deionized water with 7 times the mass of pretreated starch, adjust the pH value to 10.4, and then add a cross-linking aid at 25KV / cm and Pulse electric field treatment is carried out under the condition of 240Hz, followed by centrifugation, washing and drying to obtain starch-β-cyclodextrin; the cross-linking assistan...

Embodiment 3

[0044] An aroma sustained-release capsule includes composite microspheres 2, the composite microspheres 2 include a plurality of microsphere units, and a matching capsule shell 1 is arranged outside the composite microspheres 2. The pore diameter of the composite microsphere 2 is 60 nm, and the length of the capsule shell 1 is 200 mm; the composite microsphere 2 is a starch-β cyclodextrin composite microsphere, and the material of the capsule shell 1 is xanthan gum.

[0045] The preparation method of above-mentioned aroma sustained-release capsule, comprises the following steps:

[0046] (1) Mix β-cyclodextrin and pretreated starch in a mass ratio of 3:1, then add deionized water with 8 times the mass of pretreated starch, adjust the pH value to 10.5, and then add cross-linking assistant at 30KV / cm and Pulse electric field treatment is carried out under the condition of 250Hz, followed by centrifugation, washing and drying to obtain starch-β cyclodextrin; the cross-linking ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com