Manufacturing method of thin-wall chilled special-shaped pipe

A manufacturing method and technology of cold-hard special-shaped, applied in the field of seamless steel pipes, can solve the problems of low yield of special-shaped pipes, uneven weld surface, easy cracking, etc., and achieve the effect of improving yield and smooth weld surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] When manufacturing special-shaped pipes with a wall thickness of 0.8mm

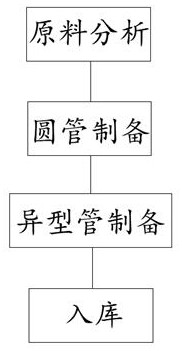

[0027] A method for manufacturing a thin-wall chilled special-shaped pipe, including adjusting and changing the plastic rebound coefficient and yield limit coefficient of the raw material when it enters the forming mold according to the thin-wall chilled thickness and Rockwell hardness of the raw material, and increasing the closed hole shape of the forming The thickness of the guide sheet, control the opening angle of the small guide and appropriately widen the width of the raw material.

[0028] Specific steps include:

[0029] 1) Raw material analysis: Choose raw materials that are appropriately widened compared with traditional raw materials, in order to ensure normal forming, welding and sizing.

[0030] Put the widened raw material into the storage bin through the loading rack, analyze the hardness and thickness of the widened raw material, thereby adjust and change the parameters when the w...

Embodiment 2

[0037] When manufacturing special-shaped pipes with a wall thickness of 0.9mm

[0038] A method for manufacturing a thin-wall chilled special-shaped pipe, including adjusting and changing the plastic rebound coefficient and yield limit coefficient of the raw material when it enters the forming mold according to the thin-wall chilled thickness and Rockwell hardness of the raw material, and increasing the closed hole shape of the forming The thickness of the guide sheet, control the opening angle of the small guide and appropriately widen the width of the raw material.

[0039] Specific steps include:

[0040] 1) Raw material analysis: Choose raw materials that are appropriately widened compared with traditional raw materials, in order to ensure normal forming, welding and sizing.

[0041] Put the widened raw material into the storage bin through the loading rack, analyze the hardness and thickness of the widened raw material, thereby adjust and change the parameters when the w...

Embodiment 3

[0048] When manufacturing special-shaped tubes with a wall thickness of 1 mm

[0049] A method for manufacturing a thin-wall chilled special-shaped pipe, including adjusting and changing the plastic rebound coefficient and yield limit coefficient of the raw material when it enters the forming mold according to the thin-wall chilled thickness and Rockwell hardness of the raw material, and increasing the closed hole shape of the forming The thickness of the guide sheet, control the opening angle of the small guide and appropriately widen the width of the raw material.

[0050] Specific steps include:

[0051] 1) Raw material analysis: Choose raw materials that are appropriately widened compared with traditional raw materials, in order to ensure normal forming, welding and sizing.

[0052]Put the widened raw material into the storage bin through the loading rack, analyze the hardness and thickness of the widened raw material, thereby adjust and change the parameters when the wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com