Sectional type rotary scanning micropore array processing device and processing method thereof

A microhole array and processing device technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of repeated pulses, continuous changes in angular velocity, and inability to guarantee the consistency of microhole processing quality, so as to improve processing efficiency, Effect of overcoming high inertia, processing efficiency and improvement of processing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

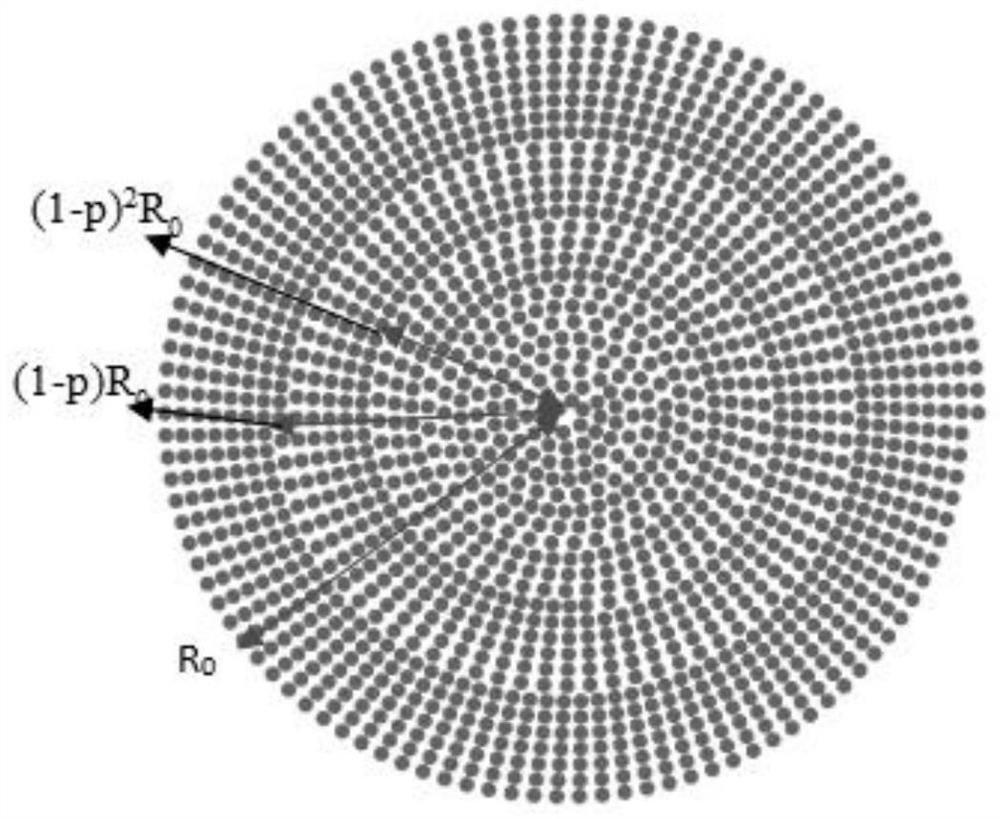

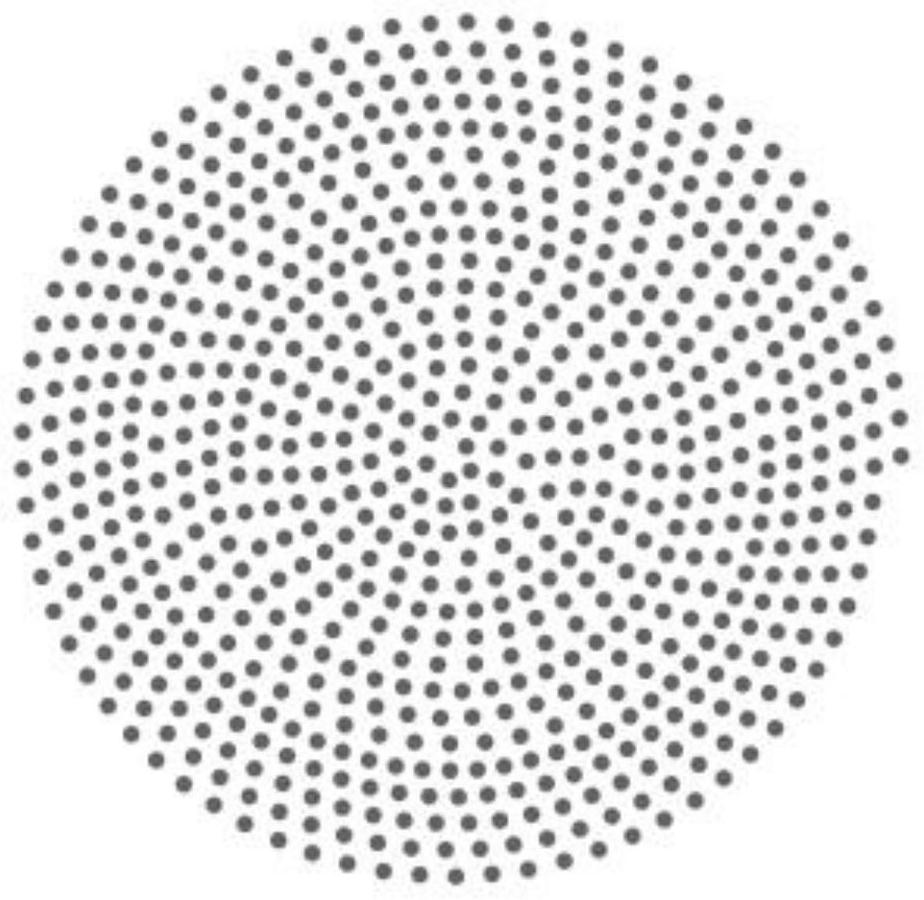

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

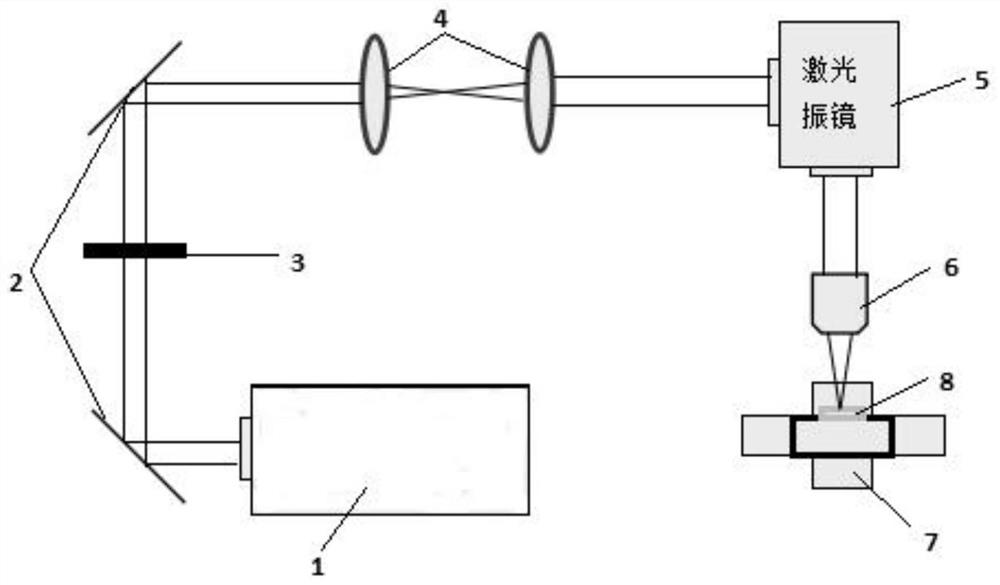

[0032] Aiming at the existing problems, the present invention provides a segmented rotary scanning microhole array processing device, including:

[0033] High repetition rate ultrafast laser 1, the high repetition rate ultrafast laser 1 generates ultrafast pulse laser;

[0034] A diaphragm 3, the diaphragm 3 is arranged at the exit end of the high-repetition-frequency ultrafast laser 1, and the diaphragm 3 adjusts the optical path of the ultrafast pulsed laser;

[0035] Convex lens 4, described convex lens 4 is provided with two and is arranged in parallel, and described convex lens 4 is arranged on the exit end of described diaphragm 3;

[0036] A laser vibrating mirror 5, the laser vibrating mirror 5 is arranged at an end of the convex lens 4 away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com