Transverse and longitudinal integrated power bogie with axle boxes capable of measuring temperature

A power bogie, integrated technology, applied in the direction of bogie, axle box, axle box installation, etc., can solve the problems of increasing the structural size and turning radius of the bogie, time-consuming and labor-intensive, narrow inner ring of the bearing, etc., so as to facilitate independent replacement and overhaul, reduce manufacturing costs, and improve structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings.

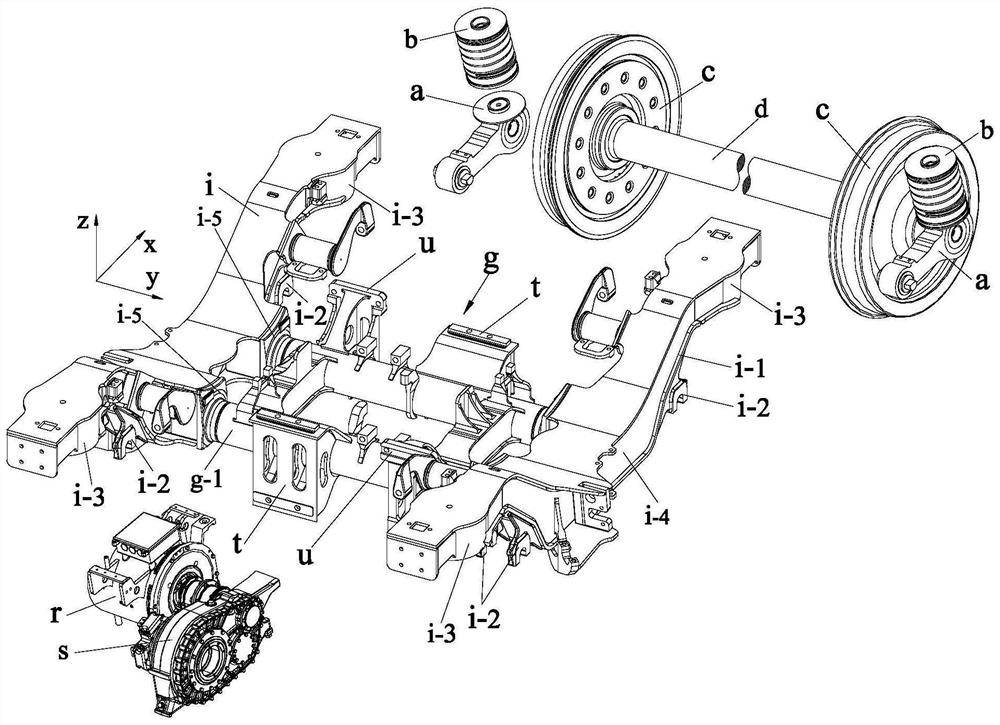

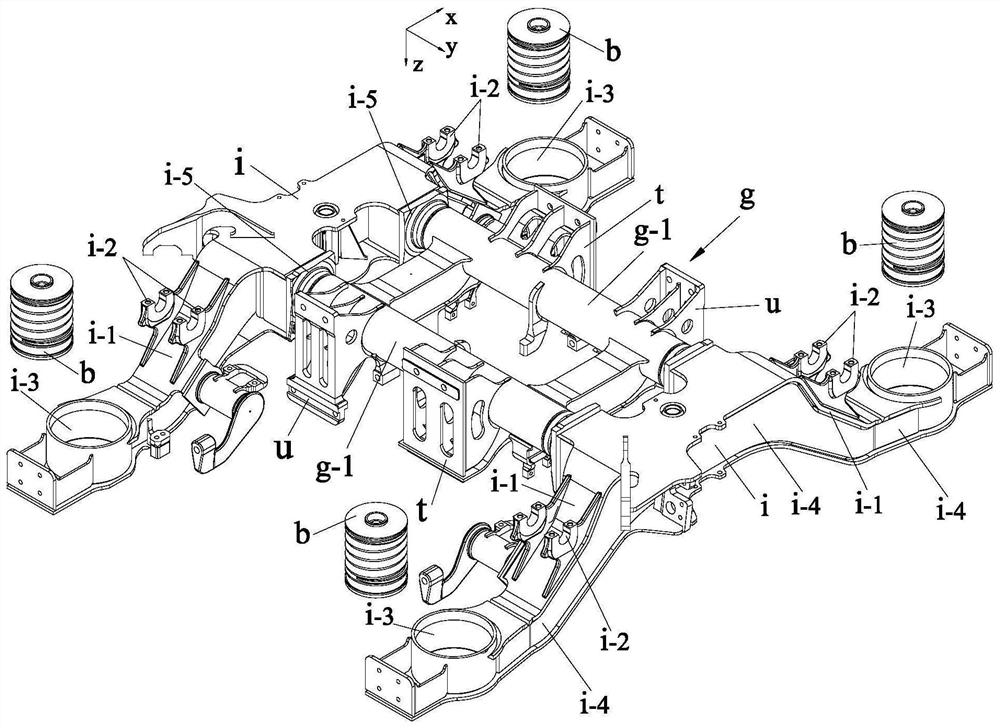

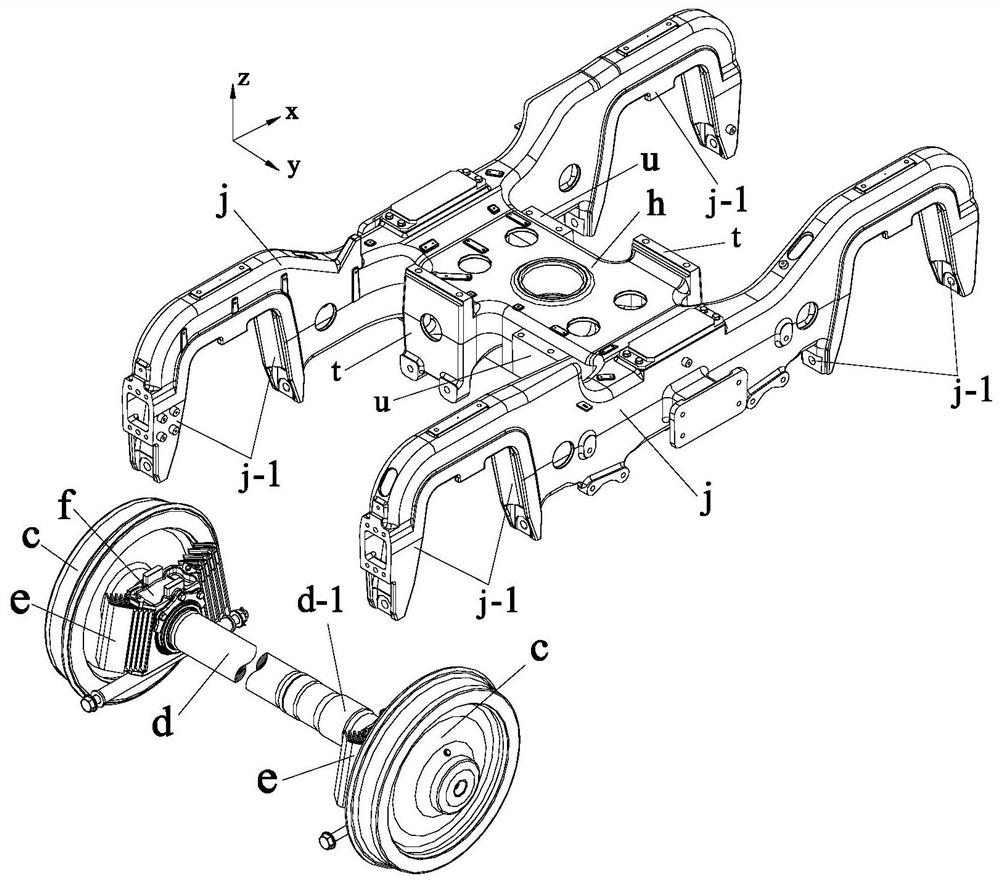

[0061] like Figure 7 to Figure 19 As shown, the horizontally and vertically integrated power bogie with temperature-measuring axleboxes of the present invention includes: a wheel set device composed of wheels and axles, a horizontally and vertically integrated interconnection frame, four ring-shaped damping axleboxes, an easy-to-return Shaft gearbox, side beam single-point suspension motor; horizontal and vertical integrated interconnection frame includes two horizontal and vertical integrated frames that are rotationally symmetrical to each other, and each horizontal and vertical integrated frame includes an integrally formed integrated side beam 1-1 and the integrated beam 1-2; the integrated side beam 1-1 includes the middle section of the side beam 1-1-1 which is the connecting part of the two bird wings and is at a lower position and two symmetrically f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com